Key Takeaways:

- Certain fleet management technologies unlock insights into asset locations, usage, and conditions.

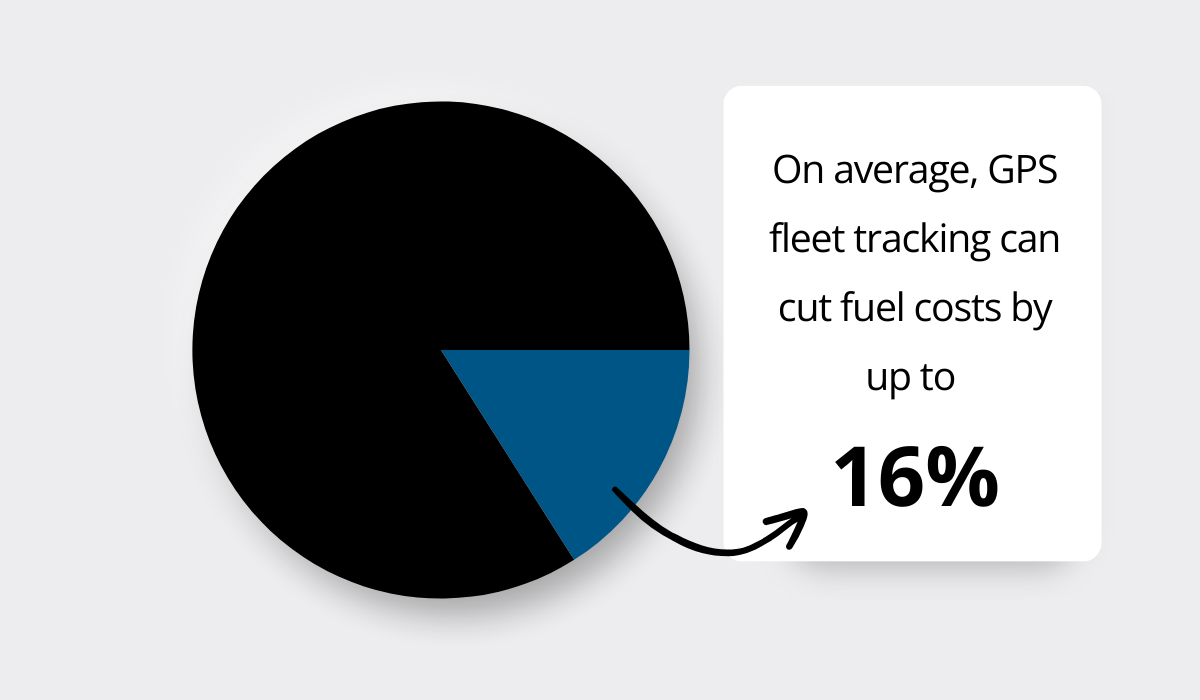

- Research shows that GPS tracking can reduce fuel costs by 16%.

- Thanks to 5G connectivity, fleet managers can now access fleet data far more quickly.

Looking for a clear and detailed guide to fleet management?

You’ve come to the right place.

In this article, you’ll discover everything you need to know about this vital and increasingly complex field:

From all the activities involved in the process to the technologies you can use to optimize your own fleet management efforts.

Ready to transform your fleet operations forever?

Let’s get started!

In this article...

What Is Fleet Management

Put simply, fleet management refers to the process of organizing, coordinating, and overseeing the entire life cycle of an organization’s vehicles and equipment.

This includes not only company-owned assets but also “grey fleet” vehicles—those owned by employees, but used for work purposes.

The field of fleet management is constantly evolving and growing.

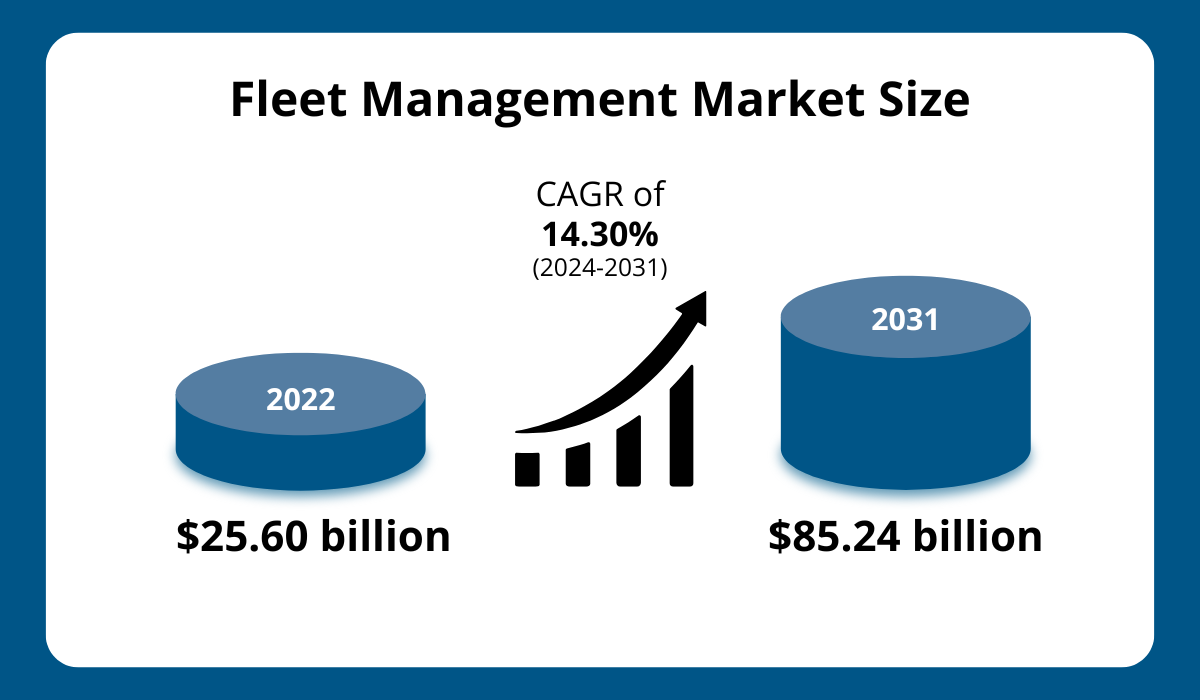

In fact, the global fleet management market, valued at USD 25.60 billion in 2022, is projected to reach USD 85.24 billion by 2031.

This significant growth is mostly driven by various technological advancements, increasing regulatory demands, and the consequent growing complexity of fleet operations.

After all, fleets play a strategically important role for companies across a wide range of industries.

So, it is not surprising that keeping them safe, efficient, and compliant requires specialized attention and innovative solutions.

What Does a Fleet Manager Do?

A fleet manager’s role is as versatile as it is demanding.

These professionals oversee both the broader strategic direction and the day-to-day operations of a business’s vehicles.

This involves a wide range of tasks, including:

- Overseeing vehicle maintenance

- Ensuring regulatory compliance

- Maintaining driver safety

- Procuring vehicles

- Tracking vehicles

- Controlling costs

And, as the field of fleet management evolves, so does the role of the fleet manager.

Regulatory rules and industry demands are continually changing, adding layers of complexity to their job.

Dave Boorman, Fleet Telematics Manager at FM Conway, an infrastructure services provider and an asphalt manufacturer, explains how the role has changed over the last decade:

“If you wind the clock back 10 years it was all about putting a bum on a seat and getting something to where you wanted it to get to. Now you’ve got to do it safely, you’ve got to do it economically, you’ve got to be sustainable in doing it and you’ve got to protect your workforce, your drivers and the members of public. […] It’s not just about getting the job done, it’s about everything is in line before you can get the job done.”

Yes, being a fleet manager is undoubtedly challenging.

But the challenge comes with opportunity.

Fleet managers are no longer just logistical coordinators: they’re now strategic contributors within organizations, driving improvements in operations and making a measurable impact.

They now have a chance to lead, innovate, and make a real difference.

How Fleet Management Improves Your Operations

So, how exactly do fleet managers make an impact?

More specifically, what are the exact benefits of effective fleet management?

Let’s find out.

Helps Manage Your Vehicle Inventory

Efficient fleet managers track assets and spare parts in real time, unlocking insights into their locations, usage, condition, and other vital information.

This level of visibility is essential for more than just effective resource allocation, though.

It’s also instrumental in ensuring that every asset is used to its fullest potential—especially when managing hundreds or even thousands of assets.

Take Superior Paving Corp, Northern Virginia’s paving and asphalt mix supply company, for example.

They monitor their asset inventory with precision, says Tyler Mitchell, the company’s former equipment manager.

This enables them to pull real-time equipment utilization and health data and ensure each machine is in the right place, at the right time, for the right job.

No equipment sits idle, and no machine is pushed to its limits.

At the same time, location data minimizes instances of asset theft or loss, further boosting efficiency.

The benefits are clear: less downtime, fewer project delays, and smoother operations overall.

Allows You to Monitor Driver Behavior

Fleet managers now have access to various technologies that monitor driver behavior and flag unsafe driving habits like speeding, harsh braking, or prolonged idling.

Leveraging this information enables them to better assess drivers’ adherence to safety and operational protocols and, ultimately, reduce accidents and vehicle wear and tear.

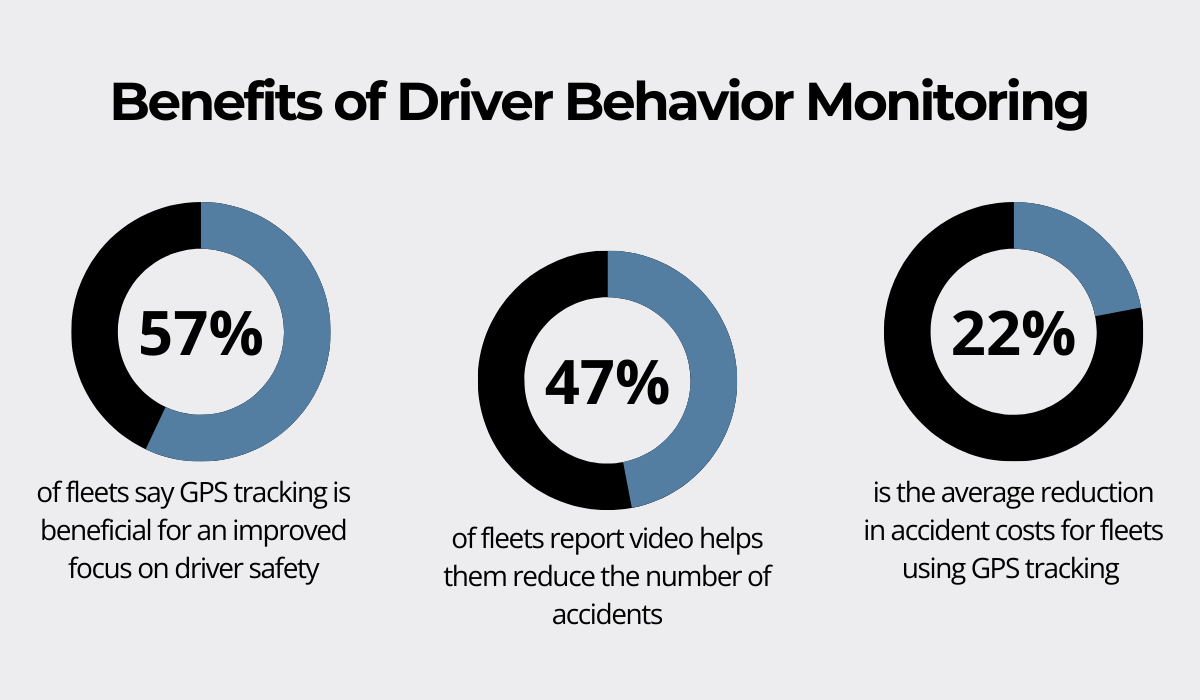

A recent Verizon Connect study illustrates just how valuable driver-monitoring tech can be.

For example, 57% of companies say GPS fleet tracking improves focus on driver safety, while 47% highlight video in particular as very effective in reducing accidents.

Most impressively, these technologies slash accident-related costs by an average of 22%.

Greencore, a supplier of chilled, frozen, and ambient foods, has already experienced these benefits firsthand.

In 2023, following a successful 8-week pilot trial, they decided to roll out the integrated telematics and camera solution across their entire fleet of 525 vans and 136 HGVs.

Jeremy Fitton, their Operations Director, explains how the system works:

It’s important to note that these tools don’t just correct unsafe behavior in real time, but also serve as the foundation for personalized driver coaching.

The result?

A strong safety culture with smarter, safer, and more cost-effective driving.

Reduces Fuel Costs

With the right fleet technology, cutting fuel costs becomes effortless.

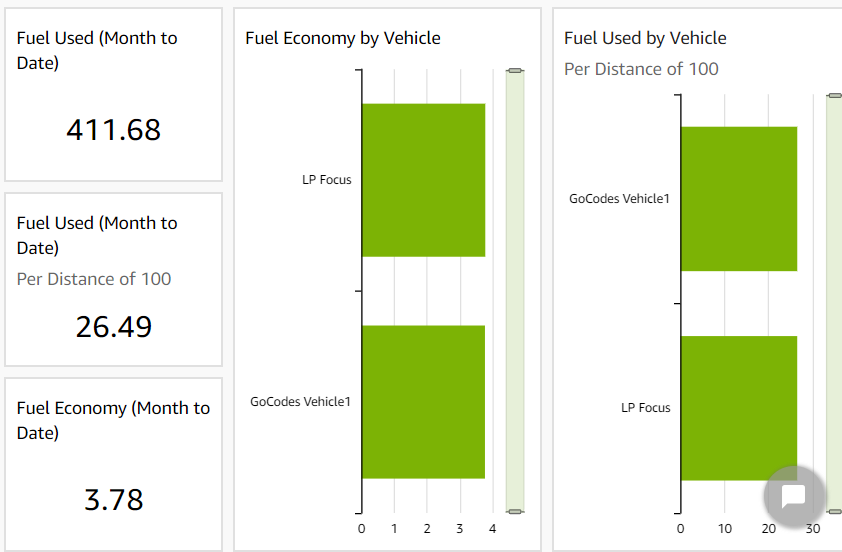

This is because fleet management tools make it easy to analyze fuel usage, pinpoint wasteful practices (like excessive idling), and take action to improve, as shown below:

And these systems are truly effective.

In fact, the Verizon Connect study we mentioned earlier has shown that fleets using GPS tracking can cut fuel costs by up to 16%.

Given that fuel expenses are a top concern for fleet managers and represent one of their largest cost areas, the impact of such savings on the bottom line can’t be ignored.

One specific way fleet tech helps reduce fuel costs is through route optimization.

Route optimization algorithms calculate the most efficient route based on distance and road conditions, minimizing unnecessary driving and reducing overall fuel consumption.

Paul Lawrence, Managing Director of fleet management technology provider AddSecure Smart Transport, explains how poorly planned routes are the number one cause of inefficient fuel use.

However, with route optimization, he says, all of that changes.

Fuel usage drops, operations run smoother, and even your environmental footprint shrinks.

It’s better for your budget, your business, and the planet.

Enables Predictive Maintenance Scheduling

Today, we can predict equipment issues before they occur, thanks to AI-driven predictive analytics.

This technology leverages both real-time and historical asset data to forecast future maintenance needs, thus addressing one of the biggest challenges in equipment upkeep.

That’s right, knowing when a repair is needed before a breakdown or accident occurs is a top concern for 44% of fleet managers, according to a J.J. Keller survey.

This is a big challenge because, if you can’t proactively schedule repairs, you risk costly unplanned downtime, project delays, and even more damage to the fleet.

Predictive maintenance, however, finally solves these problems.

No wonder more and more fleets across various industries are embracing this advanced approach.

For instance, in 2022, Singapore bus operator, SBS Transit, implemented AI- and ML-powered solutions for this very purpose.

This system was supposed to serve as an early warning system, helping technicians identify and resolve faults before they cause bus breakdowns.

And that’s precisely what it did.

In fact, thanks to this technology, the company was able to reduce asset breakdown by at least 20%.

Jeffrey Sim, Group CEO of SBS Transit, hailed the system for boosting the reliability of their fleet, too.

The bottom line?

With predictive maintenance, there’s no more need for guesswork and ineffective upkeep scheduling.

Fleet managers can now stay ahead of potential problems, keeping their assets in peak condition and operations smooth.

Technologies That Are Revolutionizing Fleet Management

Now that we understand the benefits of fleet management, it’s time to explore how exactly these advantages are unlocked.

The short answer?

Technology.

However, let’s dig a bit deeper and take a closer look at the specific tools that are transforming the field of fleet management.

Telematics

Using GPS, sensors, and other devices, telematics provides a plethora of valuable insights into asset performance, health, and use—all in real time.

This is probably why the use of this technology is growing so rapidly.

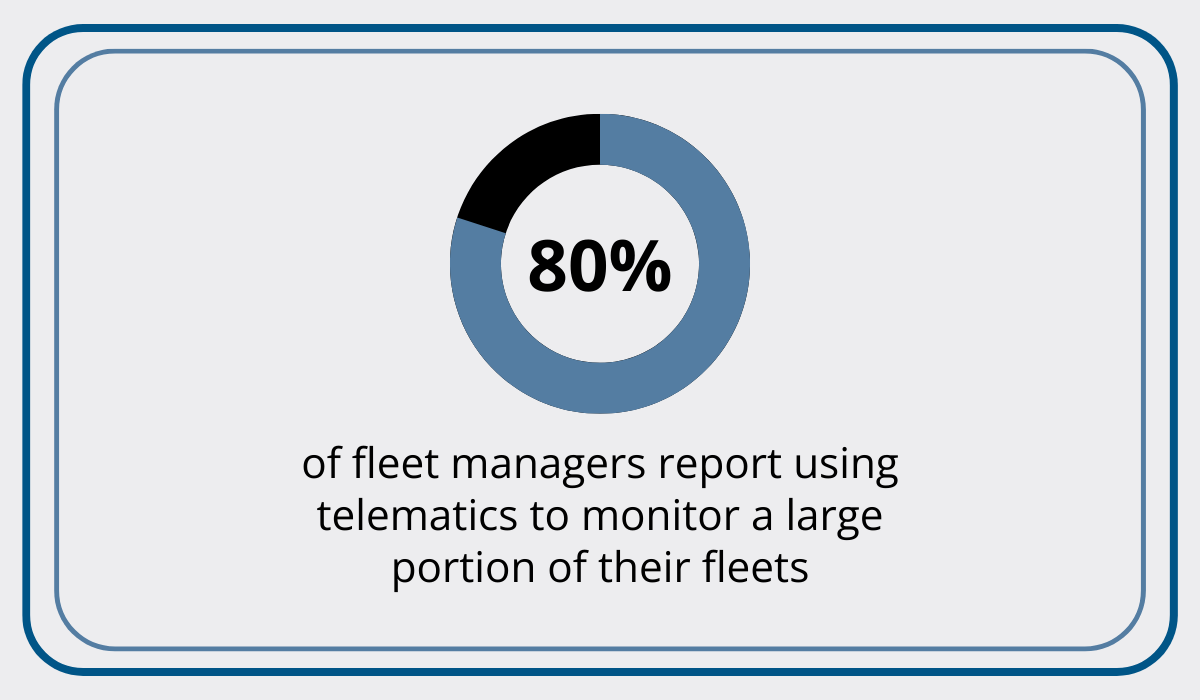

According to a SambaSafety survey, 80% of fleet managers now report using telematics across most of their fleet.

And why wouldn’t they?

There are so many benefits, from enhanced safety and extended equipment lifespan to significant cost savings and minimized operational disruptions.

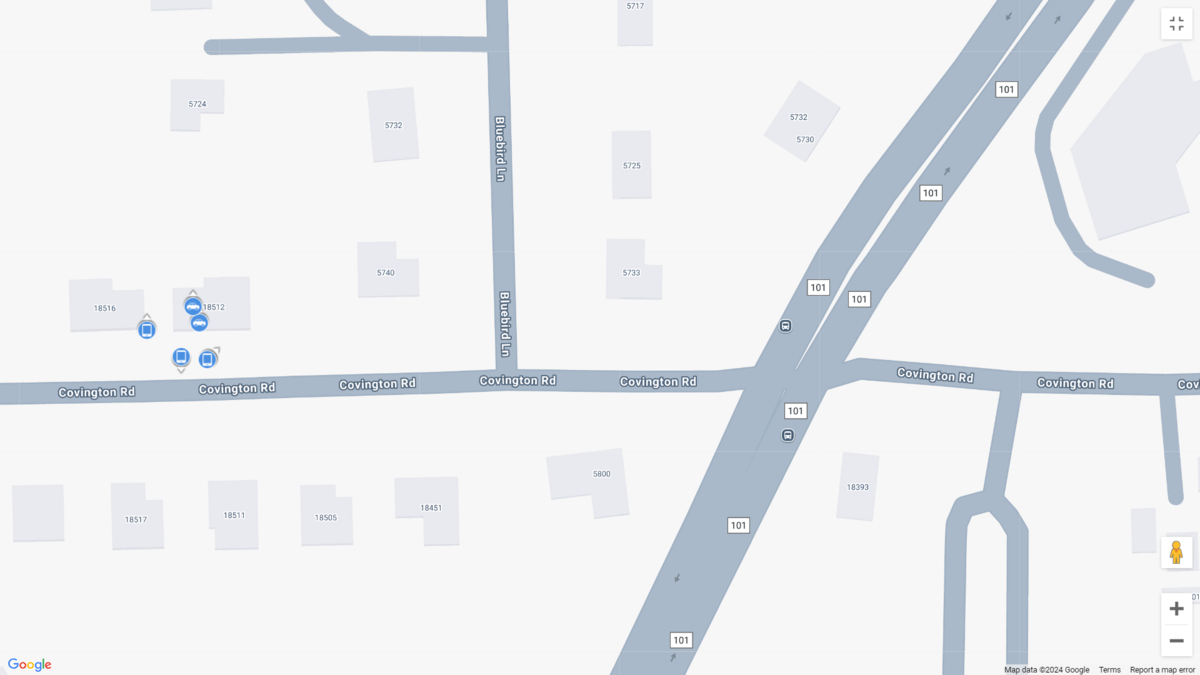

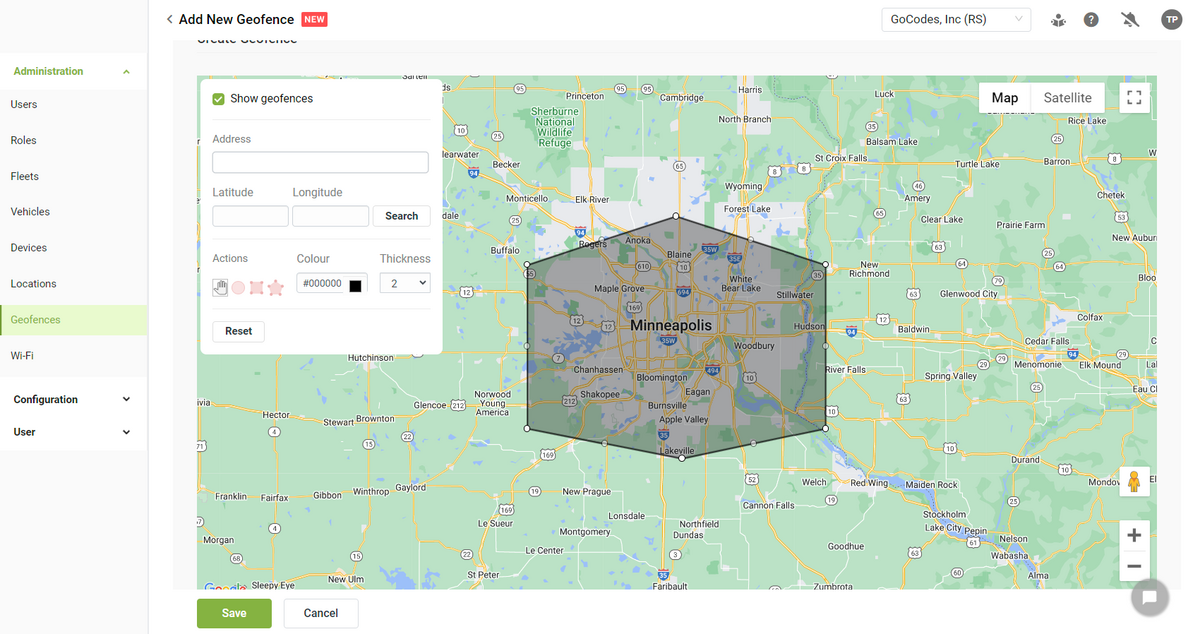

Take GoCodes Asset Tracking, for instance.

Combining our asset management software with real-time GPS trackers (shown below), you can take control of your fleet like never before.

In addition to minute-by-minute updates on asset locations, our system also captures data like speed, braking, engine hours, and more.

That way, you get a complete picture of your fleet’s movement, utilization, and condition—a perfect foundation for smarter equipment allocation and maintenance planning.

However, there’s more to it.

Our geofencing feature adds another layer of control.

It allows you to easily set up boundaries your fleet shouldn’t cross and then sends you alerts if any unauthorized movement occurs.

This helps prevent asset loss, misuse, and even theft.

So, if you’d like to learn more about GoCodes Asset Tracking and how it can take your fleet management to the next level, don’t hesitate to schedule a free consultation with our team.

After all, when it comes to rich, actionable fleet insights, nothing can match telematics.

Autonomous Vehicles

Autonomous vehicles (AVs) replace either all or at least some human input during operation, using a variety of technologies.

For example, sensors—like radar, cameras, lidar, and ultrasound—help AVs observe their surroundings, while sophisticated ML systems process these sensors’ feeds into actionable data.

This is how they’re able to, say, identify pedestrians or predict the behavior of other vehicles.

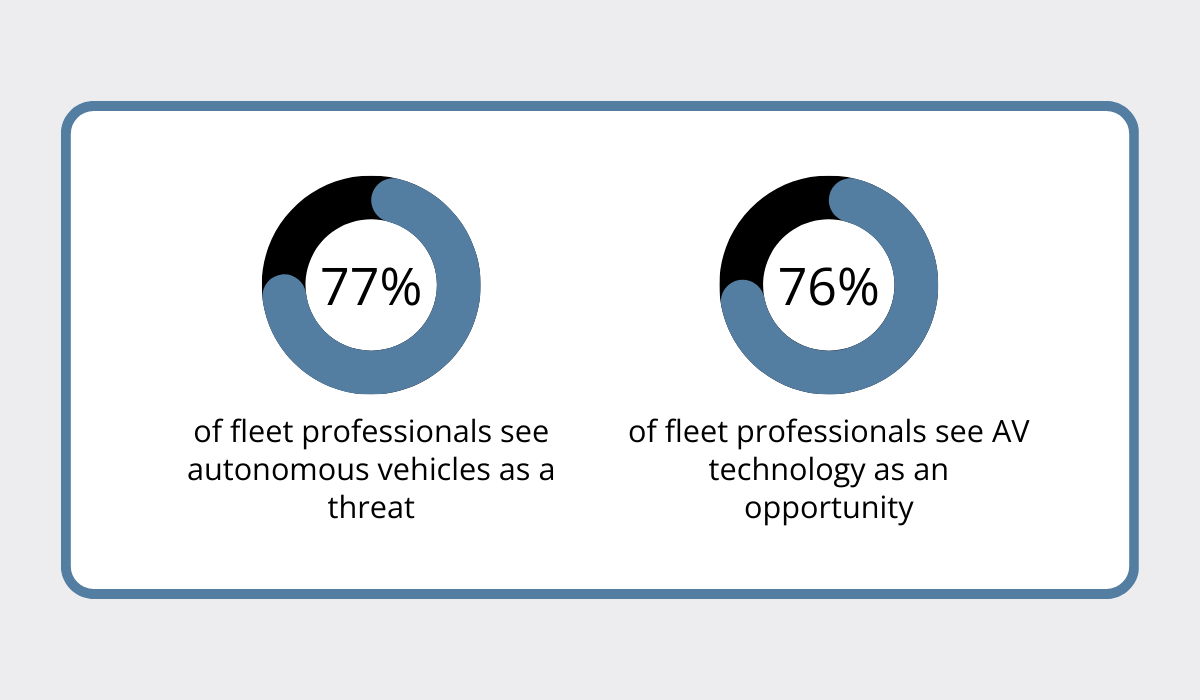

However, unlike telematics, autonomous technology hasn’t won everyone over just yet.

According to a Shell report, fleet operators are split: 77% see AVs as a threat, while 76% view them as an opportunity.

Nevertheless, AVs do have the potential to significantly improve fleet management efforts.

How?

Baddressing inefficiencies caused by human error, lowering labor costs, and increasing overall operational safety.

The construction industry, in particular, known for being dangerous and demanding, could greatly benefit from this technology.

In fact, some companies within the industry already are.

Take, for instance, the Austria-based construction group Strabag, which successfully tested a new autonomous asphalt paving technology recently.

The trial took place on a section of the A9 motorway near the Slovenian border, where Strabag is currently renovating the road.

Equipped with object recognition sensors and satellite navigation (GNSS), the autonomous paver handled the entire 180-meter trial stretch without human intervention.

Yes, Strabag’s team from Graz coordinated implementation and logistics, but the machine did all the heavy lifting itself.

Sebastian Czaja, the company’s head of TPA Group PSS (Process Stability in Road Construction), claims this is the future of paving:

All in all, AV technology is definitely not something to ignore.

In the future, we’re bound to see more and more of it, helping us increase the efficiency and cost-effectiveness of our operations.

5G Connectivity

Put simply, the rollout of 5G networks means improvements across all fleet management technologies, from telematics to autonomous driving systems.

Here are some specific benefits these networks deliver:

| High Speed | 5G can provide internet speeds up to 100 times faster than 4G, which directly translates to quicker data transfer |

| Low Latency | Latency refers to the delay before a data transfer begins following an instruction for its transfer. 5G drastically reduces this delay, making real-time communication and data processing more efficient |

| Increased Capacity | 5G networks can handle more devices at once, which is crucial for managing large fleets of vehicles |

All of this enables faster, more efficient communication between fleet systems overall, even further improving decision-making.

After all, better, more reliable connectivity is key for quick and uninterrupted data transfer between modern fleet hardware and software.

Vernon Bonser, UK and EU Sales Director at Queclink Wireless Solutions, a supplier of wireless machine-to-machine devices and solutions, elaborates:

“5G will enable seamless integration with cloud-based platforms where the hardware generates reliable data faster and the software, in turn, supports high-quality data storage, analysis, and remote monitoring. With the ever-increasing capabilities of hardware and the subsequent higher volumes of data generated, we are seeing more and more the need for high-speed, reliable data transfer.”

Ultimately, this might encourage even more fleets to start using telematics or other fleet management tools and take full advantage of all the benefits these advanced systems offer.

At the end of the day, data is king—and 5G ensures you access it more quickly and easily than ever before.

Conclusion

Hopefully, fleet management doesn’t seem so intimidating anymore.

Sure, there’s a lot to it, but with the right tools, it can be surprisingly straightforward.

In fact, now that you understand the benefits of effective fleet management, you may be eager to implement some of the available technologies, like telematics, yourself.

Here’s the key: don’t rush it.

Take a cue from some of the companies we’ve mentioned and start with a pilot program.

Experiment with the technology on a small part of your fleet and once you see the results (spoiler: they’ll likely be impressive), you can confidently roll it out across the board.

Good luck!