Tools are among the most easily lost and misplaced assets in public and private organizations. Maintaining real-time information about their location is invaluable. Tool tracking is an important function for construction companies, retail outlets, nonprofit organizations, and education establishments.

Properly applied tool tracking can lower costs, increase profit margins, boost employee accountability, and optimize preventive maintenance.

In this article...

What is a tool tracking system?

A tool tracking system is a platform that gives you information about the location, usage, quantity, and condition of the tools you own. It can involve asset tagging, software, smartphones, handheld scanners, and other forms of technology.

By harnessing this technology, even the most out-of-the-way and isolated worksite is connected to every employee who needs to access it in order to meet his or her job expectations.

Some tools are tiny and easily lost and others are difficult to miss, but they can all disappear from a worksite. Managing them across locations as they move from employee to employee protects these valuable assets.

When employees and managers scan each asset as it is used or moved, a comprehensive picture of each item’s location and health quickly emerges.

When a tool tracking system is thoughtfully installed and assiduously deployed, the investment is well worth it. An organization’s assets are put to full use, employees are more involved in daily operations, and infrastructure tools are made increasingly flexible.

Why you need to track your tools

Tool tracking systems can quickly paint a picture of how a tool landed in a particular location.

This information is not always a matter of “who stole the tool” or even “who lost the tool and how.” Both tiny items that rarely move and technology-based assets which are never in the same place are suitable for tool tracking.

Looking at how the tool traveled from one end of the warehouse to another, or from headquarters to a remote job site in another state, can help decision-makers plan more efficient supply chains and storage.

Tool tracking can eliminate inventory discrepancies, outdated data, or frustrating duplications.

Simple spreadsheets and inventory item counts aren’t enough to provide a complete and in-depth overview of not only where your tools are, but what their condition is.

Tracking systems tailored to the business they serve can inform decision-makers and employees about:

- which tools are unavailable because of repairs

- how many items are across town versus the amount in storage

- which are due for preventive maintenance or deep cleaning

Tracking your tools also gives information about how employees interact and communicate and allow management teams to maximize natural flows of information and networking for a more efficient schedule.

Besides, this data can provide hard numbers about where tools are requested, how they were delivered, and how bulk discounts and company procurement procedures are utilized.

Technologies used for tool tracking

The many technologies available for tool tracking means that organizations both large and small and in all kinds of fields can benefit from this practice.

Some technologies are better suited for a moving fleet, and others for smaller tools that move through departments but never leave the building. Let’s review them individually.

GPS

GPS tool tracking benefits companies running several projects at once in disparate locations. This form of technology is similar to what you use in your car to drive from one point to another. Because of its widespread use, GPS tracking is the most readily available and can be easily integrated into devices that your employees might already use.

When a company’s asset is on the move (even under its own power), GPS can track it in real-time. The tracker can be easily placed on the asset itself or associated with a specific employee.

This form of tool tracking can also provide alerts to decision-makers, managers, and employees at specified intervals.

Since its scanning range is virtually unlimited, GPS systems are good choices for tools spread over large distances and many branches or worksites.

GPS is generally regarded as the most globally accurate tracking system. It relies on satellites stationed in geosynchronous orbit to relay the location of your asset. The system usually runs on batteries and is easily placed on the exterior of most tools.

Most GPS devices can become part of a tool tracking system without the headache of hard wiring.

On the downside, GPS systems may not work in cloudy or other inclement weather. They are also vulnerable to satellite outages. Because of its overall flexibility and precision, GPS tool tracking tends to require a heftier initial investment than other systems.

RFID

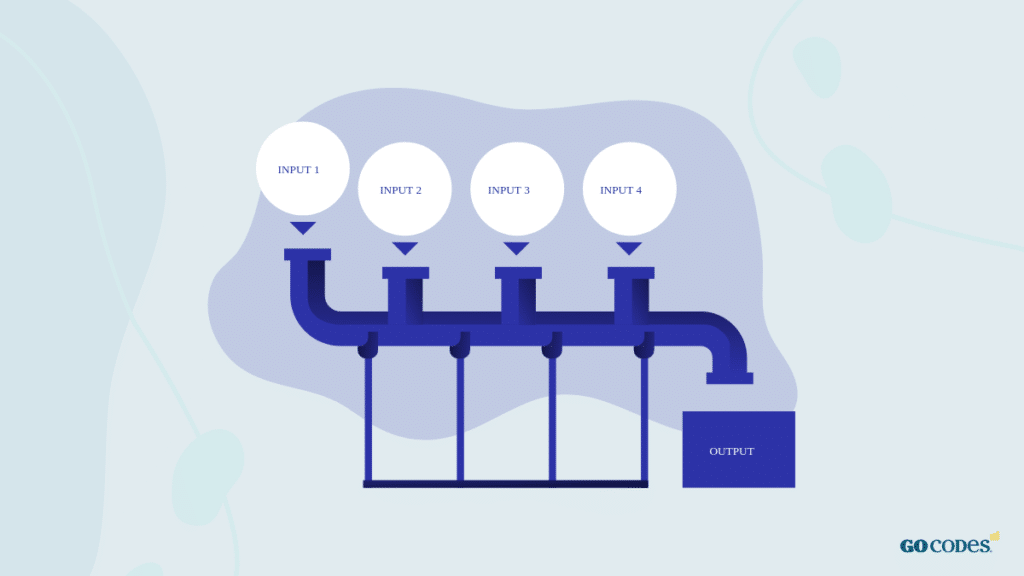

RFID is an acronym for Radio Frequency-Identification. It works with tags that have been placed on an asset. These tags are then tracked by radio waves issued from a nearby antenna.

As the item and its tag travel through the scanning field of the antenna, its signal is located and confirmed. That pinpoints its location, as well as other information.

Since RFID can function as an automated “set it and forget it” tracking tool, it eliminates programming time after the initial setup. Its ability to auto-track also means it’s less prone to human error.

Although it doesn’t have the global range of a GPS unit, an RFID system can still read data from great distances at a lower cost.

RFID data is easily password enabled and its output encrypted, which makes it a great choice for organizations that prioritize security.

The plastic-covered tags typically used with an RFID system are eco friendly because they can come from biodegradable sources and are reusable.

Companies needing to track tools that incorporate large amounts of liquid and metal might not work well with an RFID system. The radio signal emitted by the tags might become scrambled or weakened by these materials.

In addition, organizations with massive numbers of assets to tag should seriously consider the labor efficiency and cost of implementing RFID, as bringing the entire system online usually takes longer than other methods.

QR Codes

If you have a smartphone, you have probably scanned a QR code. QR stands for “Quick Response,” and it is ramping up as one of the most popular forms of asset tracking for larger corporations—many times replacing or appearing alongside traditional retail barcodes.

Originally developed to track cars as they moved down an assembly line, QR codes can store much more data than a bar code. They look like squares with black and white markings and can be minimized or enlarged as much as necessary.

A tool tracking structure based on QR codes has the built-in advantage of providing technological advancement with a system likely already familiar to most employees.

QR codes don’t require specialized equipment such as hand scanners, and their integration can easily involve tablets and phones. The technology is fast, easy to work with, and versatile.

Such systems might be a good fit for companies that require real-time geolocation tracking. They demand point-to-point input; the information stored in the code is dependent upon input accuracy and regular scanning.

However, QR code readers enabled with GPS, such as smartphones, allow for tracking a mobile or fixed asset along with its geospatial information. We at GoCodes Asset Tracking use GPS-enabled asset tracking, patented in 2015.

It’s a workaround to having real-time data. You just need to scan the item regularly.

Doing that provides you with near real-time visibility into its geospatial data over time. If the tool moves after you’ve scanned it, the next scanning will reveal where it is at the moment.

How a Tool Tracking System Can Help You

Benefits of tool tracking are as varied and as flexible as the organizations which use them—from libraries to construction contractors to retail establishments.

Here are some of the many ways a tool tracking system can benefit your business.

Compliance

When properly used, tool tracking systems quietly amass and organize all the data your company needs to prove compliance during audit processes and safety checks.

Whether it’s time to file taxes, provide information for a permit, work with the Occupational Safety and Health Administration (OSHA), or drop company specs while bidding for a contract, tool tracking keeps your data organized and up to date.

Employees who need to access information about company assets can do so, even from the other side of the world, or when support staff is not present.

Flexibility in time of crisis

In unfortunate circumstances, commerce and companies need to be agile and quickly adapt to new situations.

Take the COVID-19 pandemic for example; every possible industry was affected, whether by government shutdowns, supply chain challenges, or unexpected runs on products such as toilet paper and soap.

Some companies found themselves in a vastly different industry overnight—for example, Anheuser-Busch suddenly needed to pivot from manufacturing beer to producing hand sanitizer.

Having a robust tool tracking system enabled such companies to know precisely which assets were at hand and what their condition was during a time of global crisis.

Some companies that have never imagined impact from a pandemic found themselves with empty warehouses and employees locked down at home.

Since gyms, yoga studios, and recreational sports suddenly disappeared from daily life, for instance, home fitness equipment became a hot market.

In March 2020, sales of items like small weights, home treadmills, and exercise bikes soared to 130% above what they were in the previous year, according to The NPD Group.

In turn, the massive exercise equipment demand also affected delivery services, home playground options, and Internet businesses providing the bandwidth for streaming exercise classes online.

The companies which responded best to this sudden spike were the ones most prepared for such an unforeseen event—those with the ability to process which tools they had, precisely when they needed them.

Optimize Communication

Tool tracking can do much more than simply track tools. There are many dimensions in which your system can collect data. It can inform decision-makers about which employees prefer which tools, and why.

Brief surveys or requests for opinions as part of the tool-tracking process helps employees feel like part of a larger project and provide an opportunity to gather such reflections right after the employee has interacted with the asset.

Memories are sharp and the employee might feel more comfortable interrelating with anonymized data rather than in a face-to-face meeting, or in a survey which is conducted months after the tool has left the employee’s hands.

Tips for Tool Tracking

Once you have put in a tool tracking system in place, take the time to make the most of your investment. Here are some tips for optimizing your tracking process.

Begin Accurately

Your tool tracking system is only as good as the information it receives, both in the beginning and as it receives and sorts data day by day.

However, even a top-of-the-line, cutting-edge system with full employee participation won’t yield much return if the system was based on faulty data or incomplete information.

Taking the time to fully survey the assets at hand, as well as their condition, might seem tedious at first. Still, this work will yield massive returns when you can find information on a tool’s location, price, maintenance schedule, and warranty information all at the touch of a button.

Continue Updating

It’s disheartening to think of a company that devoted a lot of time and money all to see it go to waste when the tool tracking system is not used past its first few weeks or months.

Just as a workable tool tracking system must begin on a solid foundation, each layer built on top of it must reflect consistency, accuracy, and changes in inventory. If you don’t update the information about tools in the tracking system, it will become useless and obsolete. And that brings us to the next point.

Train Thoroughly

The key to obtaining ongoing accurate information is to train employees to input it correctly. Simply handing a scanner to a new employee and saying “You’ll figure it out” is asking for missing or incorrectly scanned data.

Regular employee training at sensible intervals can keep your tool tracking system up to date and functioning smoothly. Ensure that new employees are properly trained on tool tracking as a distinct job duty as it can install good habits from the start.

Most importantly, communicate to employees why tool tracking is necessary and beneficial to help them realize how vital their role is. They are then more inclined to take part and do so properly.

Plan for Preventive Maintenance

If you communicate that you take preventive maintenance seriously, your employees will realize that you are concerned for their safety, as well as the quality of their work and your service.

Since tool tracking provides such valuable information where preventive maintenance is concerned, it alerts managers and employees when an asset might be unavailable because it is either in repair or undergoing regular checks.

This allows the team to shift schedules, find alternate solutions, and have extra equipment on hand to compensate for the asset’s downtime.

Software for Tool Tracking

While deciding on which type of tool tracking system is the optimal choice for your organization, keep the importance of software in mind.

The “best” software is that which fits your company’s needs and streamlines data retrieval about each asset.

Here are some things to consider when looking for a perfect tool tracking software:

- how easily the software can accommodate growth and crisis

- what kind of infrastructure changes must take place to accommodate the system

- ease of training employees and managers in utilizing each aspect

- whether your company must collaborate across departments

No matter what kind of industry you serve or what size your organization is, there are certain aspects of tool tracking software you should look for.

These are a few:

- end to end tool management—the software solution involves easy installation, implementation, and automatic or simply handled updates

- a flexible system which can pivot with your organization

- location information on the exact position of your assets

- simple, intuitive check in and check out for employees who might not use the system regularly

- real-time updating

- ability to quickly compile and present data

- automatic maintenance scheduling and reminders

- cloud-based data, which allows employees to access information across the system

- simple integration and upscaling

- free trial period to ensure the system is a good fit

GoCodes Asset Tracking asset tracking software covers all of these features and some more. Get acquainted with its full functionalities via this video.

Conclusion

A tool tracking system is essential for companies and organizations with assets that are on the move. Properly implemented, tool tracking saves time and money. It also provides the ability to make informed decisions and make rapid changes in times of fast growth or crisis.

By choosing thoughtfully designed software and a flexible, user-friendly asset tagging system, tool tracking will serve you as well as the tools themselves.