If your renter or buyer is on the other side of the world, you’ll have to find a way to ship the equipment to them. The most popular and cost-effective way to do this with heavy equipment is to import the machinery using nautical vessels.

However, many containers get damaged in transport, which can cause damage to the cargo inside. In fact, 65% of all load-related damage happens because of incorrect securement or container stuffing, which means it could have been prevented.

This article will explain how to properly prepare your heavy machinery for transport and what you need to know before shipping.

If you follow the advice from this article, your equipment will safely arrive at its destination.

In this article...

Preparing the Equipment for Transport

Before you can ship your heavy equipment overseas, you have to prepare and secure it properly. Otherwise, it may encounter issues during transport.

The first thing you need to do is go through the manufacturer’s manual. It will tell you exactly what parts of the equipment you can safely detach and how you can secure it during transport.

Both these pieces of information will ensure that your machinery stays safe during overseas transport.

Cargo securement should be your top priority when transporting your equipment overseas. The type of securement system you will use will depend on the size of the equipment.

It will determine whether you should opt for cabling, different types of rope, webbing, straps, or other methods of tying down the equipment, so it doesn’t move during transport.

Remember that containers can roll over or fall, damaging any equipment you didn’t secure properly.

Then it’s time to prepare and clean the equipment for transport. Start with emptying the machinery of all liquid substances, including fuel, oil, and hydraulic fluid. You don’t want your equipment to suffer any spillage.

After that, you should disconnect the batteries and any alarm systems, as you don’t want them to go off during transport. Of course, if you opt for a roll-on/roll-off (RO-RO) mode of transportation, you’ll have to keep the batteries running.

Since there’s always a chance that your equipment might be exposed to harsh weather conditions during its journey overseas, you must protect it. A great way to do this is by rust-proofing, which decreases the chance of rust forming on your equipment.

Some standard rust-proofing methods that can be useful are plating, galvanizing, and painting.

A tin and zinc mix that is used in plating helps protect your machinery from corrosion. On the other hand, when you galvanize, you must use zinc and steel to coat your equipment. Most people use pure zinc as the last coat due to its shock-absorbing properties.

If you opt for painting, you’ll cover your machinery with a new, separate layer of protection from outside influences in the form of a coat of paint.

Finally, don’t forget to ensure there’s enough room for workers to safely unload and unpack the equipment. You have to be sure that nothing falls on the workers and that they don’t have to risk their safety in any way to retrieve your machinery.

Knowing the Equipment Size and Specs

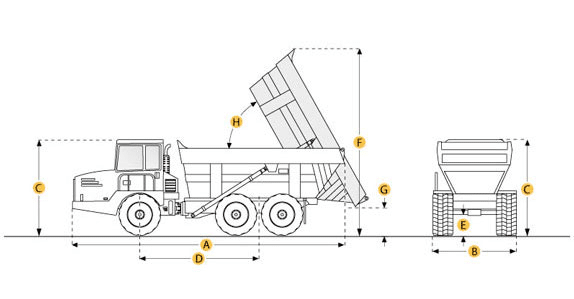

Always know your equipment inside and out, including the machinery details and specifications.

The mode of transport and destination port (namely, the regulations and requirements they impose) are just two out of many reasons you as the owner should be aware of your machinery’s specifications, including the weight and height.

For instance, if your equipment is too heavy for the ship you have in mind, you won’t be able to ship it overseas using the transport mode you selected, which means your entire plan will fall apart. So, knowing the size helps you pick the correct-sized ship.

The image below shows the most critical measurements of a dump truck, and you should be aware of them to understand what size of container or trailer you need if you’re opting for those options.

If you’re using the RO-RO method, you should check what type of equipment the ship in question can handle.

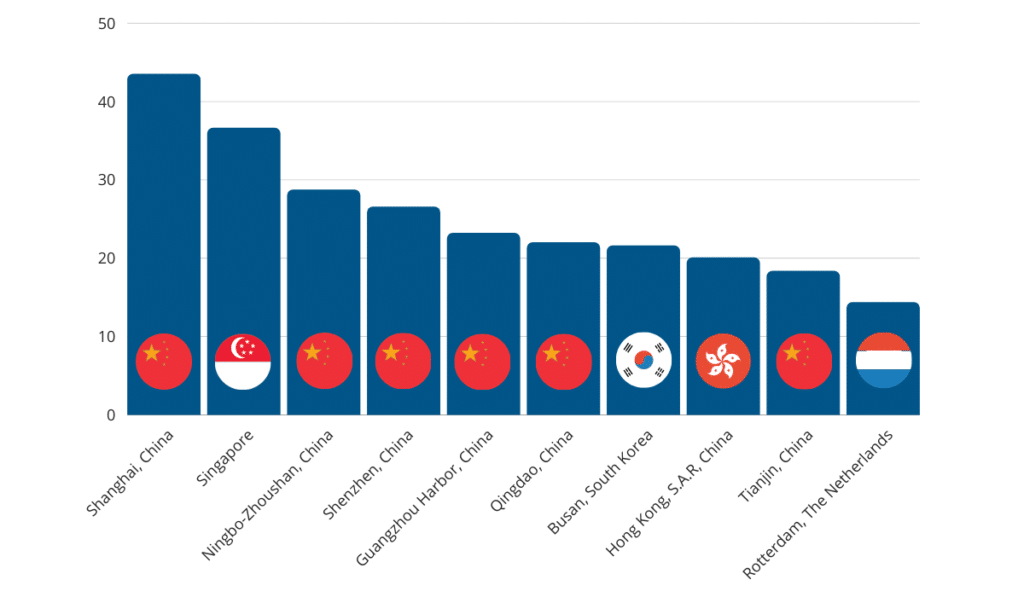

Then, think of the destination port. Where do you want to ship your equipment? If you did your research, you know that not every port can handle every ship.

If you’re sending your machinery to one of the biggest ports in the world, there shouldn’t be any problems on the receiving side, as those ports are prepared for receiving all kinds of goods.

However, if the port is smaller, you should definitely look into the acceptable weight and size of the load to be sure the destination port can accommodate your cargo.

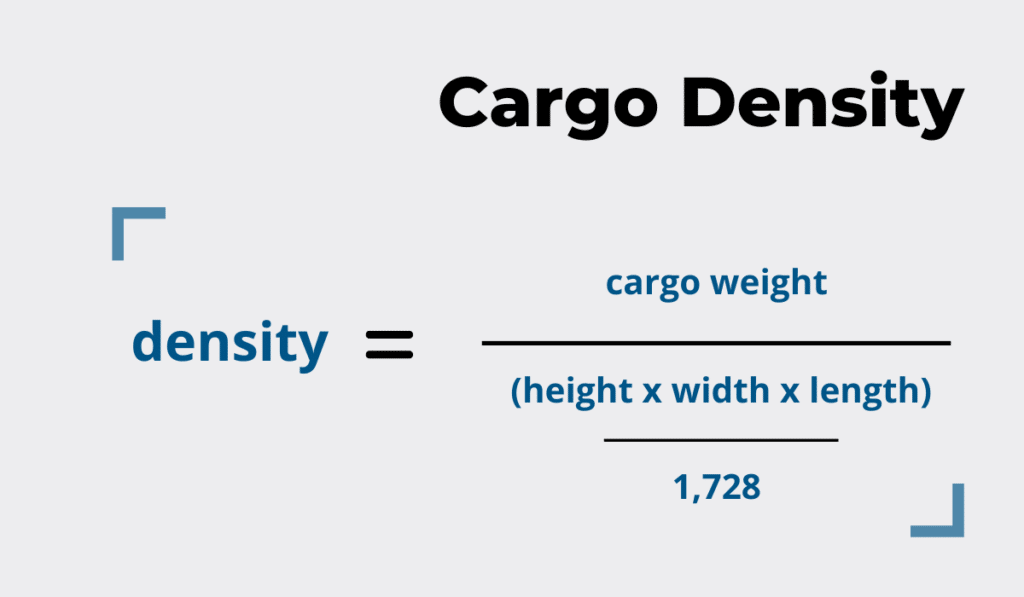

The easiest way to determine the size of your cargo is to calculate its density.

This measure is the weight of your shipment expressed in pounds per cubic foot. When calculating, make sure to take each aspect of the cargo into account, including pallets or other types of packaging.

First, you have to multiply the height, width, and length of the shipment, which will amount to its total number of cubic inches. Then, divide that number by 1,728, which is the number of cubic inches in a foot to get your cargo’s total cubic feet.

Then, divide the weight of your cargo by the total cubic feet to get density or the pounds per cubic feet value.

Now that you know the density of the equipment you’re sending along, you’ll have an easier time determining the best shipping options for you. But first, let’s look into some other requirements you’ll have to meet.

Gathering Equipment Documentation

One of the chief activities that precede heavy equipment shipping is getting all your documentation in order.

Without the necessary documents, you won’t even be able to get the machinery out of its port of origin, let alone deliver it to the buyer/renter.

Besides, every country has different regulations for heavy equipment shipping, so make sure to get familiar with the relevant rules and customs requirements. You don’t want to be breaking any laws by accident.

Some countries will want to see both the proof of ownership and insurance documents before allowing someone to use the equipment on their territory.

The documents you’ll need include:

| Document | Purpose |

| Ownership records | Prove you’re the equipment’s rightful owner. Without such records, the equipment is as good as stolen, so you can get into legal trouble for handling it. |

| Packing list | Lists everything you intend to ship so the customs, allowing anyone else who has to inspect the shipment to understand what you’ve listed and what you’re actually sending. |

| Shipper and consignee ID | Identifies the people sending and receiving the equipment for a better understanding of the parties involved. This is especially important for customers as some people may be prohibited from receiving heavy machinery shipments, for instance, if they’ve had previous troubles with the law. |

| Power of attorney form | Serves to prove that the company is shipping the machine legally. If this form is missing, whoever is charged with inspecting the equipment can treat the transporting activity as theft. |

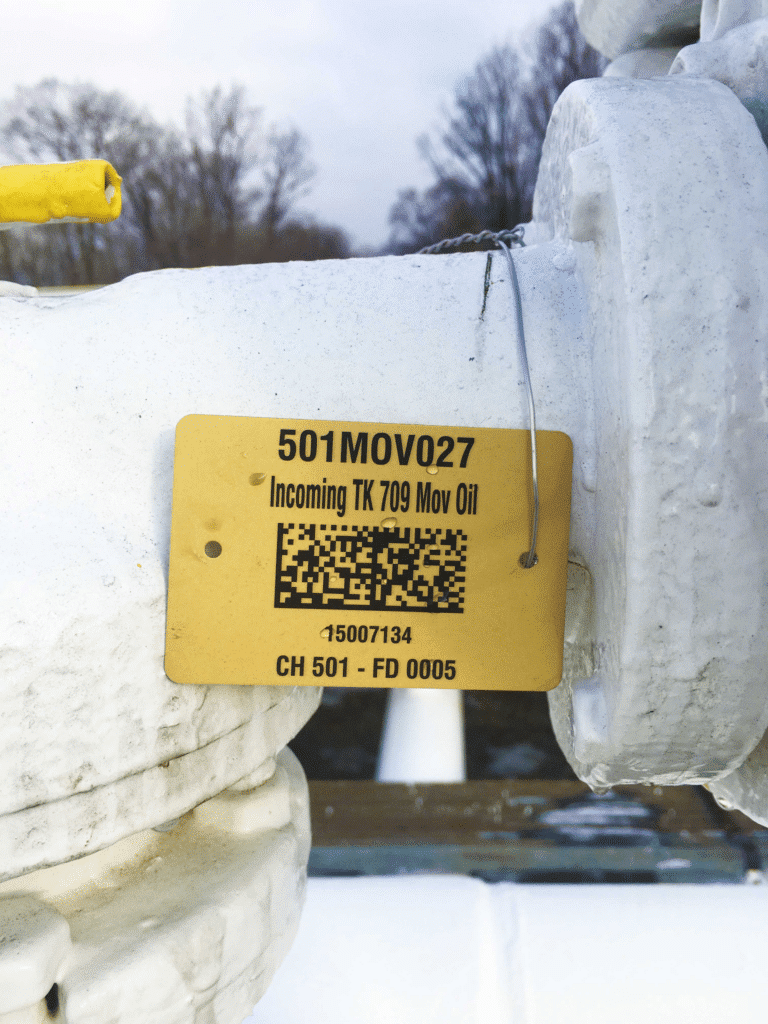

If you often ship equipment overseas or have to send multiple machines at once, it is a good idea to invest in software that lets you track equipment, as well as its documentation.

Such software is relatively easy to use: simply log the equipment’s details into the system and attach any supporting documents. You should also tag the machinery with a QR code, a durable tag, or a barcode.

Once scanned, the QR code leads the user to the machine’s page to easily access the necessary documentation.

So, if you’re shipping your equipment overseas, such software will allow you to have all the required documentation with you wherever you are, as long as you have your phone at hand.

Customs Checks and Other Freight Regulations

When going through customs, you’ll have to present two filled-out forms, one for the country of origin and the other for the destination country.

The forms include information on the equipment you’re shipping, your business, and the person who will receive the machinery.

You’ll also have to pay a fee at customs for importing the equipment into another country.

Customs base the price on the value of your shipment and the regulations of the destination country.

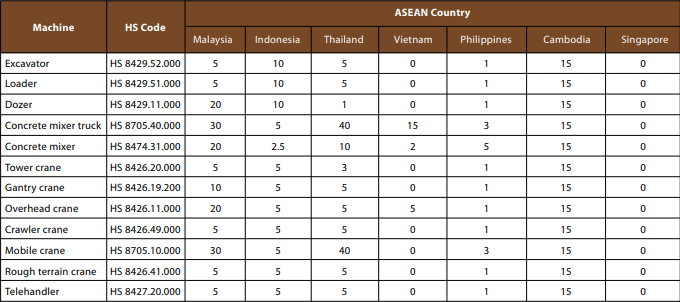

Some countries will take a low percentage of the total amount (5% or less) or won’t charge a fee at all, while others will make you pay a small fortune to import your machine.

If you look at the information above, you’ll see that countries like Singapore and the Philippines keep their fees low, so importing heavy machinery there is a bargain.

However, other countries aren’t that lenient. Cambodia’s fees equal 15% of the equipment’s value, while Malaysia’s fees increase to 20 and 30%.

Consider the fact that a small excavator costs anywhere between $80,000 to $150,000. To export the cheapest excavator into Cambodia, you’d have to pay a $12,000 fee.

The highest import fee out of all ASEAN countries is definitely Thailand, which charges 40% for concrete mixer trucks and mobile cranes.

Additionally, when shipping heavy equipment to Europe, bear in mind that you’ll have to pay a fee of 25% if you’re importing from the US as of November 2020.

This rule applies to some types of shovel and crawler loaders for now. Of course, the US also has the same tariff for equipment imported from Europe since October 2019.

The point is that you have to be aware of what you can expect at customs, so it’s best to get informed before even venturing into shipping heavy machinery overseas.

When you have all the necessary information, you can determine if it’s a wise move, i.e., whether transporting the equipment will cost you more than you’ll earn from the sale.

What Are Your Shipping Options

The final question you have to ask yourself is how you will get your equipment onto the ship.

The two most popular shipping methods are the roll-on/roll-off (RO-RO) and container shipping.

The RO-RO option allows you to drive machinery on and off the ship with the help of loading ramps.

Since you don’t have to use a rack or a container, you won’t waste time loading and unloading cargo, so it takes significantly less time to drive the equipment on and off the ship.

However, there are some downsides to this option.

First, not every ship can accommodate this method as certain vessels only accept containers.

Then, there aren’t as many sail dates for RO-RO vessels. At times, such ships only sail out when there is enough cargo for them to do so, which means you’ll have to wait until enough people need to ship their heavy equipment overseas to be able to send yours on its way.

Therefore, the container option might be a lot more suitable for you if time is of the essence and you can’t afford to wait for weeks for a vessel to sail out.

In this case, you’ll use a large open or closed container to store your equipment during transport, and you’ll load it onto and off the ship that way.

One of the most popular container types is the flat rack, which allows you to place your equipment on a rack and bring it onto the ship that way.

It is a form of a container with hollow sides, so the cargo can be as wide as you want, and it will still fit onto the rack.

Flat racks are primarily used for transporting equipment or vehicles with unusual dimensions. In other words, you can use them to ship cargo that won’t fit into a closed container. Because of this, they’re frequently used by those who need to ship heavy machinery.

Your shipping options will significantly depend on the cost. The price can vary greatly depending on aspects like density, destination, insurance, and priority.

Density is a vital factor. Some vessels may even refuse your machinery if the container is too dense. Others might charge you extra or require you to use runners to gain height and decrease the density.

Most ports and countries accept container vessels, which means that selecting that form of shipping gives you more choice in terms of the destination.

On the other hand, if you opt for the RO-RO method, you’ll have fewer options, which means it will also cost you more.

Insuring your cargo is obligatory for almost all shipping companies. Depending on the size and value of your machinery, some providers might even require you to pay for more than one policy.

The reason is simple: large equipment poses significant risks to the vessel, employees, and other cargo.

Besides, there’s a chance your container might get lost at sea. Around 3,000 were lost in 2020, and the number was already up to 1,000 in April of 2021.

Finally, priority will also affect the price.

If you need something to be shipped as soon as possible, you’ll have to pay extra. Otherwise, you’ll have to wait until there is room for your cargo on a vessel that accepts the type of packaging you’ve selected.

So, when figuring out how much it will cost you to ship your heavy equipment overseas, don’t forget about these critical four points!

Conclusion

When thinking about shipping your heavy machinery overseas, you have to take different factors into account. Namely, you have to know the equipment’s size and density to pick the right shipping option.

Once you know how you’ll ship the machinery, you should prepare it for shipping with an additional layer of safety.

Depending on the destination country, you have to have all the related documentation ready and be prepared to pay an import fee.

On top of that, you should be aware of all the customs rules and both the origin and destination country’s heavy equipment shipping regulations.

When you account for all of the above, you make sure your equipment will get shipped without a hitch.