Key Takeaways:

- Certain label types can last multiple decades and withstand temperatures up to 400°F.

- By not applying asset labels properly, you risk shortening their useful life.

- Those who implement QR code tags can easily track vital asset data, like location and maintenance history.

Tagging your assets can be an answer to all kinds of operational headaches, from theft to underutilized equipment.

But before you invest in asset tags, wouldn’t it be wise to learn as much as you can about them?

That’s where this guide comes in.

In it, we’re breaking down everything you need to know about permanent asset labels—different types, durability, application tips, and the impressive benefits they bring.

By the end, you’ll be better equipped to make informed decisions and elevate your asset management to the next level.

Let’s get started.

In this article...

Are QR Code Labels Permanent?

The short answer: it depends.

The durability of QR code asset labels is greatly influenced by the material from which they are made.

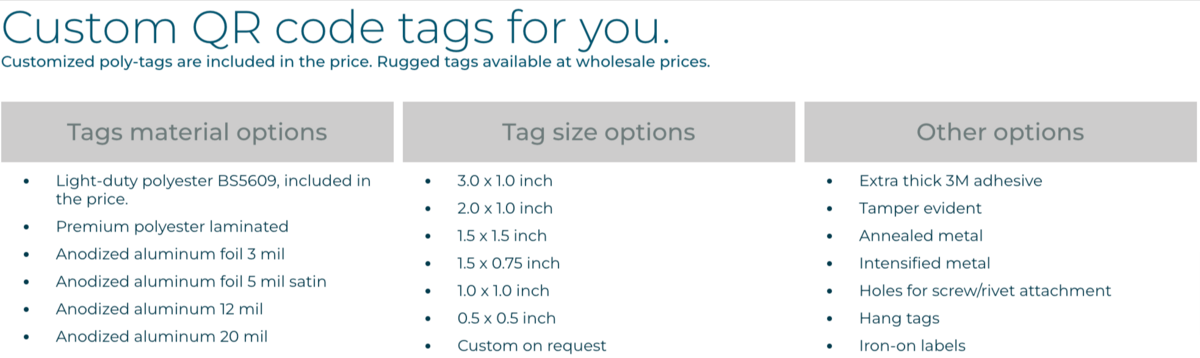

At GoCodes Asset Tracking, we provide labels in various sizes and materials, ranging from light-duty polyester to rugged industrial hang tags, as shown below:

Some of these are for indoor use only, while others are built to withstand harsh conditions and offer long-lasting performance.

Let’s break it down.

Our Standard service includes print-your-own labels, designed to be printed using your office laser printer.

While you can use any material your printer supports, we recommend the Avery material for extra resilience.

These light-duty labels are suitable for indoor use only.

Our Premium and Professional services include more durable options.

For one, there are our BS5609 (or standard) poly labels.

These 5 mm thick, 2 x 1-inch labels are water and chemical-resistant with a permanent adhesive backing, which makes them ideal for IT equipment and tools used indoors.

However, for more demanding applications, consider our premium polyester labels.

Subsurface printed, these 2 mm-thick labels with 2 mm permanent adhesive provide an added layer of protection against solvents, caustics, acids, and mild abrasion.

Finally, our anodized aluminum options are perfect for those seeking maximum durability.

You can choose between 3 mm metal foil labels with permanent adhesive backing and 8-63 mm metal tags that come with permanent adhesive, pre-drilled holes, or both.

Both options feature excellent peel strength and resistance to heat and chemicals, withstanding temperatures from -40°F to about 400°F.

Below, you’ll find a summary of each type and their features:

| Standard Polyester | Premium Polyester | Metal Foil | Metal | |

|---|---|---|---|---|

| Service temperature | up to 250°F (for short periods) | up to 250°F (for short periods) | up to 300°F | up to 400°F |

| Durability | 2-3 years | 2-3 years, up to 7 | Ten years | Multiple decades |

| Description | Water and chemical-resistant. Best for IT equipment and tools that are used indoors | Can withstand mild cleaners, mild acids, oil, and water. It provides greater durability than standard poly labels due to subsurface printing | Bendable and perfect for equipment that’s used outdoors and exposed to the elements | The most durable option. Can be used in almost any kind of environment |

But, if you’re still unsure which option is best for your needs, feel free to contact us for personalized recommendations.

And remember: how you apply the labels can also make a big difference in their longevity.

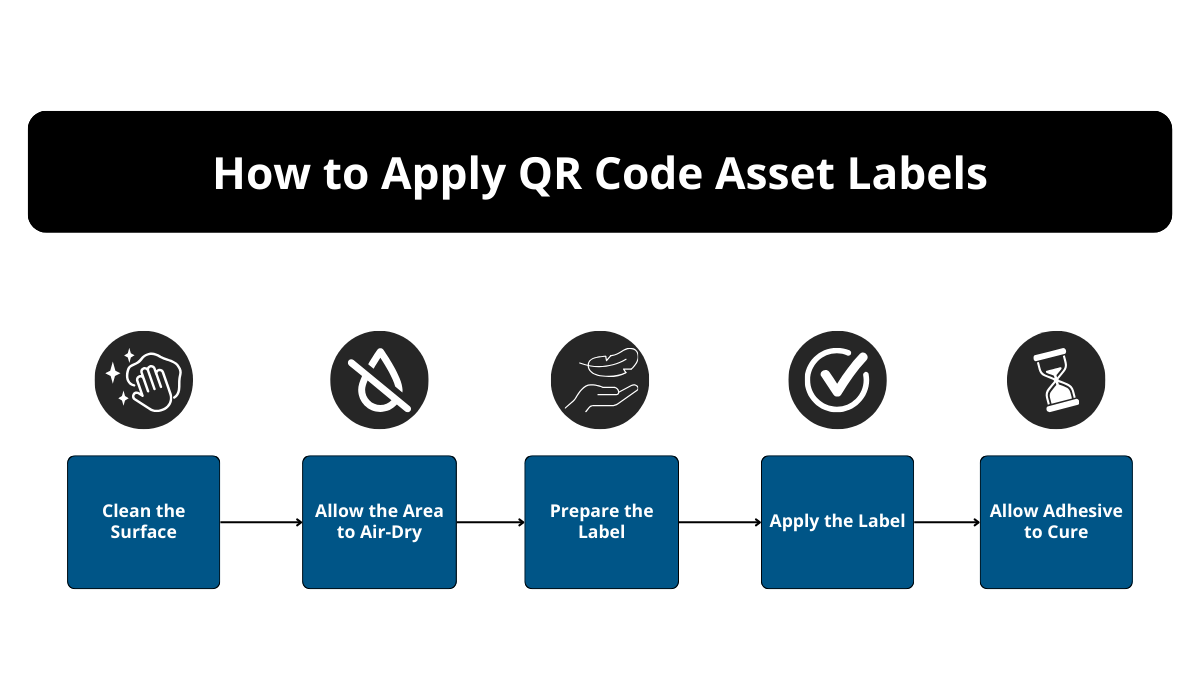

How to Apply Permanent Labels

Applying your labels properly is the key to getting the most out of them and ensuring they last as long as possible.

Follow these simple steps to achieve the best results:

Start by cleaning the surface where the label will be applied.

You can use an industrial cleaning solution or isopropyl alcohol to remove any grease, oil, wax, moisture, silicone mold release, or dirt.

This is critical for proper adhesion, so make sure the area is spotless.

Once cleaned, let the area air-dry completely as any remaining moisture can interfere with the bond.

When peeling the label from its liner, avoid touching the adhesive side. This ensures the adhesive remains clean and effective.

Hold the label by its edges and set it over the spot where you plan to affix it.

Keep in mind that placement matters too, so, make sure the label is in a visible and easily accessible location.

Once in place, apply the label firmly to the surface.

Start from the center and press outward to release any trapped air, ensuring all edges are securely bonded.

This video from Seton shows the entire process, so give it a watch for further clarification:

And one last thing: once the label is secure, resist the temptation to “test” its hold.

The adhesive needs time to cure—between 48 and 72 hours—so let it stay undisturbed during this period.

Why You Need Permanent QR Code Labels for Your Equipment

QR code labels aren’t just for show; they’re a real game-changer for your operational efficiency and bottom line.

Let’s explore some specific benefits they bring to the table.

They Streamline Equipment Tracking

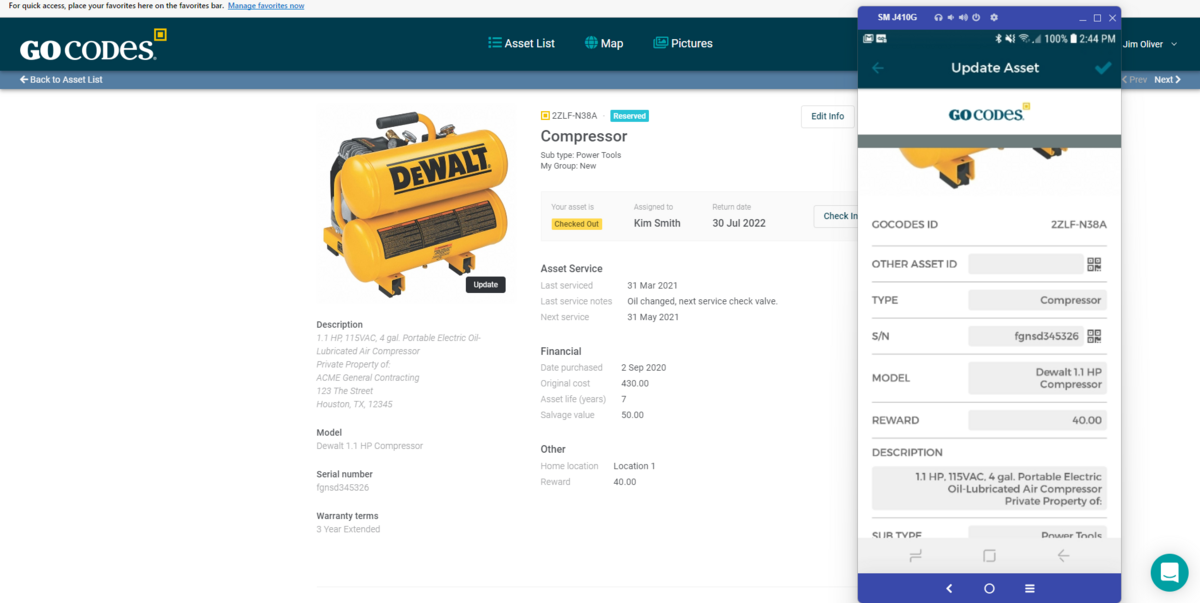

QR code labels offer instant access to all essential equipment details, including location, usage history, maintenance records, warranty information, and more.

Here is an example of a typical asset view accessible through QR codes:

QR code-powered equipment tracking completely transforms the way you manage your assets.

It keeps all the vital data up-to-date and accurate, in turn empowering you to allocate your machinery or tools more strategically and minimize instances of loss and theft.

Ultimately, this boosts your productivity and bottom line.

As Soeren Brogaard, CEO of a SaaS-based IoT solution for construction, Trackunit, says, tracking assets across job sites without a proper system is a significant time waste:

He adds that this becomes particularly problematic in time-critical jobs, where having the right tool is essential to completing tasks and keeping operations moving smoothly.

However, QR code tags change that by providing unmatched visibility into your valuable equipment’s movements and status.

Take J&M Keystone, Inc., a leading San Diego restoration contractor, as an example.

With GoCodes Asset Tracking labels, they were able to drastically reduce equipment losses and associated costs.

Lee Sherman, their former Operations Manager, explains how the company was losing substantial money due to misplaced tools before they implemented this tracking solution:

Luckily, the labels turned out to be an effective and convenient way to track and recover equipment, quickly paying for themselves through cost savings they unlocked:

“Through [GoCodes Asset Tracking], we’ve got our equipment loss down, probably closer to $1,500 per year.”

So, how does it work?

It’s very simple.

Each time a QR code label is scanned for asset check-in/check-out, the location of the update is recorded in the GoCodes Asset Tracking software.

Therefore, when workers need to find a specific piece of equipment, they can simply check their phone or computer to see its last known whereabouts, as shown in the image below.

And the best part?

You don’t even need specialized hardware for these tags to work.

They Don’t Require Special Equipment

That’s right, QR code labels don’t require any specialized tools in order to be used.

This means you don’t have to buy multiple expensive scanners, which often get misplaced anyway.

Instead, your workers can use the smartphones they already have and feel comfortable using.

In fact, according to the 2021 JBKnowledge ConTech Report, 90% of contractors and construction workers already use their smartphones daily for work purposes.

Therefore, adopting QR code asset management won’t feel like such a drastic change, as they’ll be using something they’re quite familiar with.

The same goes for our GoCodes Asset Tracking labels, too. All you need for them to work is the scanner in the GoCodes Asset Tracking app.

The app is user-friendly, even for those less tech-savvy, providing easy access to critical asset data on-the-go.

You can see what it looks like below:

So, for those looking to get started with our solution, the setup is straightforward: you just install the app and order permanent labels.

You’ll then receive an onboarding email with simple instructions and a link to a form where you can submit your shipping and label design details.

Once we receive the form, we’ll send you a digital PDF proof of your label design within one business day.

After the proof has been approved by you, we’ll print and ship your labels.

And that’s all there is to it.

At the end of the day, what good is your asset management system if it’s too complicated to set up and figure out?

With QR code labels, you get an intuitive, hassle-free solution every employee will love to use.

They Are Durable in Harsh Environments

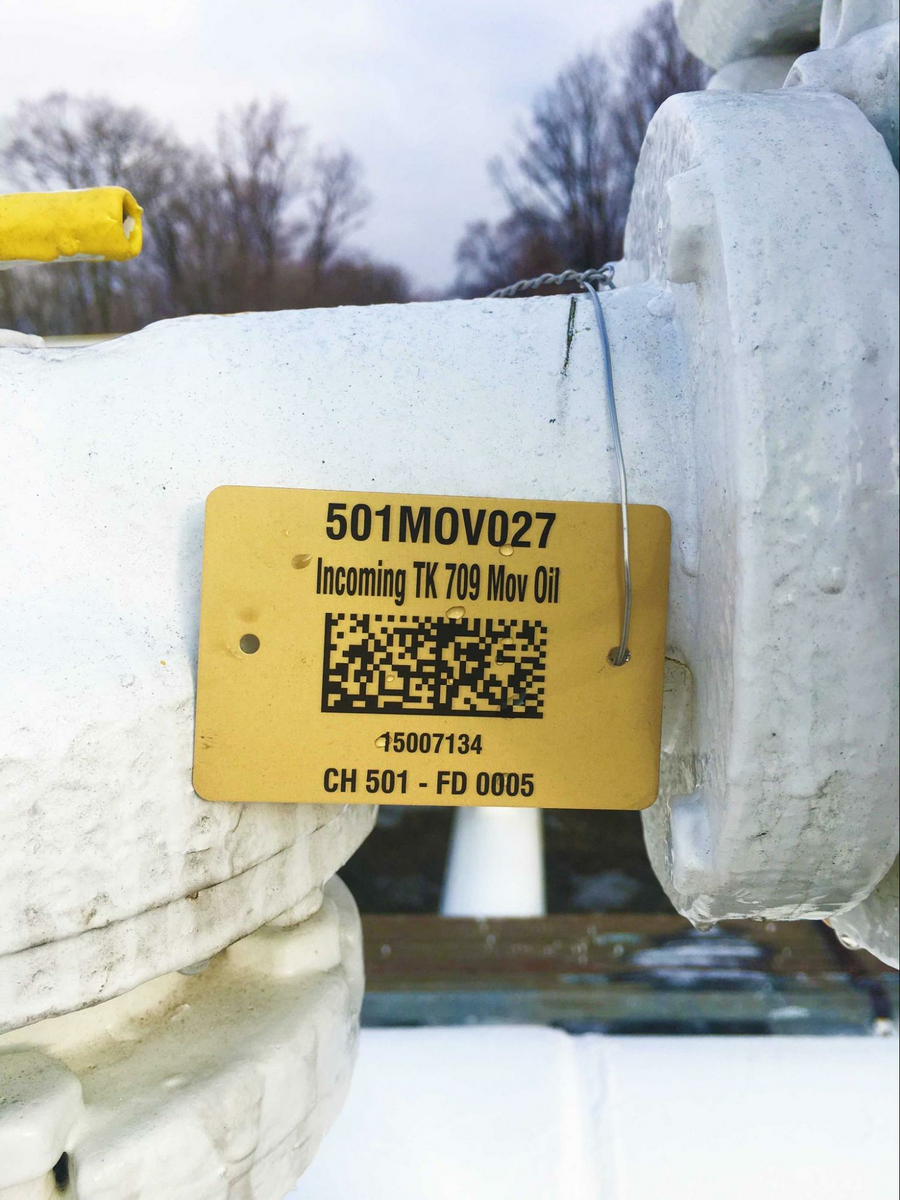

Permanent QR code labels (like the one you see below) are specifically designed to withstand harsh conditions, including extreme weather, dirt, and heavy usage.

This ensures they resist fading, peeling, or degradation, and stay legible and fully functional over time.

That’s why QR code asset labels are ideal for industries operating in challenging environments, such as construction.

Anyone who works in this sector knows that durability is paramount.

After all, regardless of the season or project scope, the nature of the work is tough on assets—along with the labels attached to them.

Take, for example, summer construction.

It doesn’t just bring high temperatures, but all sorts of different challenges, says Jacob Sherman, Manager at DEVELON, a construction equipment manufacturer.

He adds that, in certain regions, high humidity during the summer months can accelerate corrosion and rust on equipment, further complicating maintenance efforts.

However, winter is no easier, presenting a whole new set of obstacles.

Danny Freeman, Product Manager at Volvo Construction Equipment, elaborates:

In addition to these environmental factors, assets in construction and other similar industries are also frequently exposed to chemicals, corrosive substances, and mechanical stress.

If all these conditions can take a toll on equipment, they are certainly harsh on asset labels, too.

And if QR codes get damaged, this can lead to scanning errors, disrupt workflows, and create inefficiencies in tracking or inventory processes.

Durable QR code labels, however, preserve the integrity of the encoded data, ensuring reliable and accurate information retrieval—even in the toughest environments.

Conclusion

Now that you’re familiar with permanent asset labels, it’s time to choose the right ones for your equipment.

Consider the assets you want to track, their operating environment, and the durability they require.

However, don’t stop at the labels—check if the vendor provides compatible asset management software.

After all, the labels won’t do much if they aren’t connected to a system.

Ensure the software is user-friendly, just like the labels, and take advantage of free trials to confirm it meets your needs.

This is the smartest way to evaluate the system before committing to a purchase.