Rising costs, endless maintenance issues, safety concerns.

Fleet management has never been more challenging than it is today. Last year, fleet operational costs reached an all-time record in the U.S. Thus, maximizing performance can mean survival in this increasingly competitive market.

That’s why we’ve put together this comprehensive guide to transform your fleet performance.

Whether you run a construction equipment fleet or manage delivery vehicles (or something else entirely), you’ll discover proven strategies to reduce costs, improve safety, and boost efficiency.

From route optimization to preventive maintenance, each approach is designed to help you gain control over your operations.

Let’s explore the specific tactics that will help you turn your fleet into a true business asset.

In this article...

Optimize Your Routes and Schedules

Route optimization is more than just finding the shortest path between two points – it’s about maximizing efficiency across your entire fleet operation.

According to the Upper, poor route planning can increase travel time, fuel consumption, and vehicle wear and tear, directly impacting your bottom line.

Route optimization involves many steps and it may seem daunting – but it’s essential to maximizing performance.

In fact, if not done properly, it can have devastating consequences.

Take the school bus disaster in Louisville, Kentucky – a route optimization software misuse led to children ending up in wrong destinations, en masse.

Source: Google.com

While this incident highlights the importance of proper implementation, it also stresses why advanced technology has become vital for modern fleet operations.

Modern GPS tracking and route optimization tools have revolutionized how fleets operate.

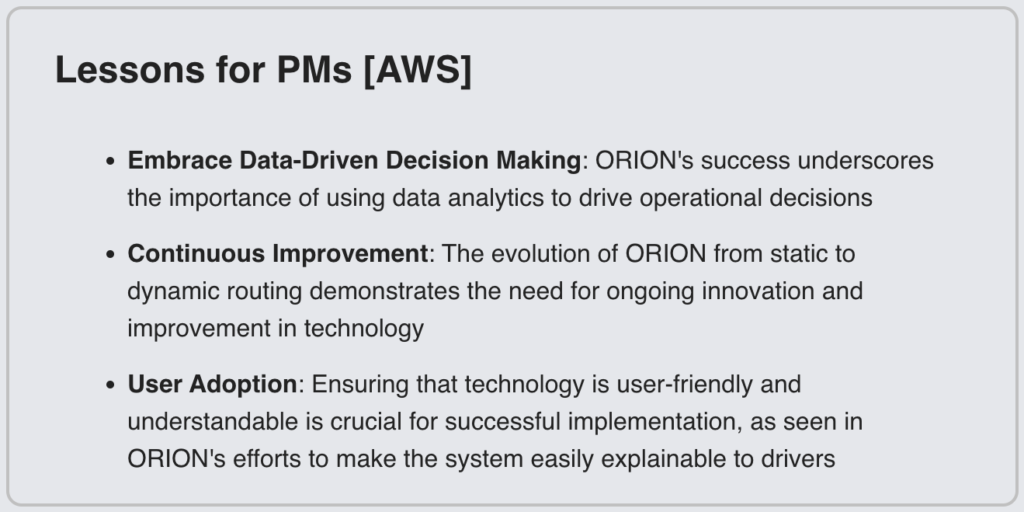

For instance, UPS famously saved millions of gallons of fuel annually by implementing their ORION (On-Road Integrated Optimization and Navigation) system, which helps drivers optimize their routes in real time.

Here are the conclusions Product Monk drew from this success story:

Source: Product Monk

This quick story emphasizes how important data-driven decision-making is.

That’s where telematics help, especially when they integrate traffic data.

Real-time traffic data is a smart way to ensure timely deliveries, reduce operational costs, and make any necessary improvements to routes.

To implement effective route optimization follow these practices:

- Utilize GPS tracking systems to monitor vehicle locations and movements

- Implement real-time traffic monitoring to avoid congestion

- Analyze historical data to identify patterns and optimize schedules

- Use telematics data to track and improve route efficiency

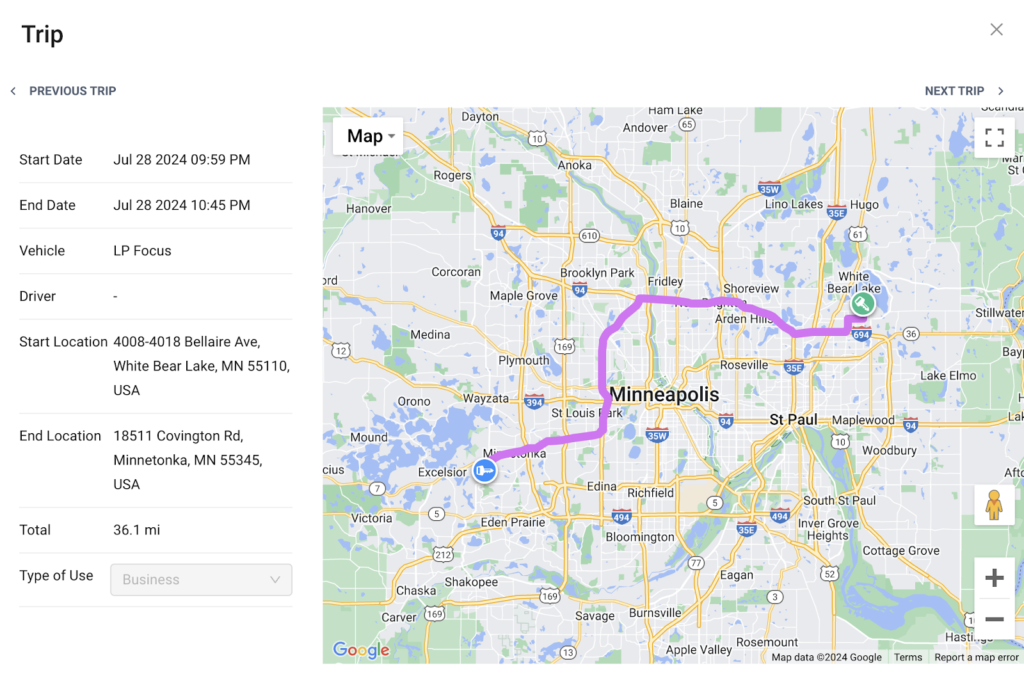

Even without traffic monitoring capabilities, vehicle tracking can provide invaluable insights.

For instance, they can get a simple image like this.

Source: GoCodes Asset Tracking

With that information at their fingertips, fleet managers can observe past trips, compare them, and decide which routes need improving.

These are straightforward methods that are easy to master and promise a more efficient way forward. But optimizing routes and schedules is just one of the many things you can do to maximize fleet performance.

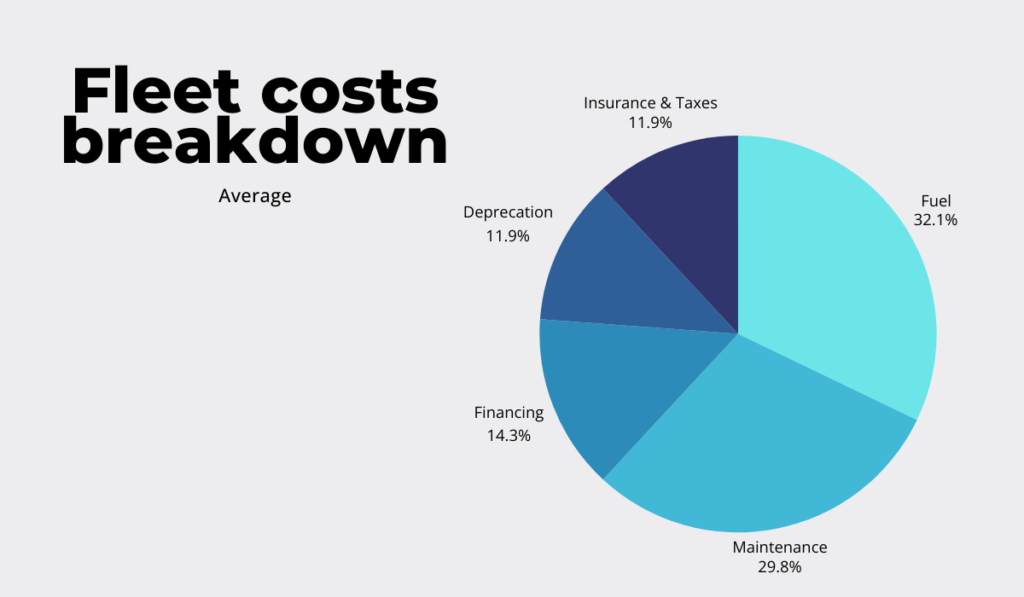

Monitor Fuel Consumption

Fuel typically represents at least 30% of a fleet’s total operating costs, so it’s safe to say it’s one of the most crucial expenses to manage.

Source: Ubivio

Modern fuel management systems have transformed how fleet managers track and optimize fuel usage – now, we have access to detailed insights that weren’t possible just a few years ago.

The data backs this up – companies using telematics report an average of 25% reduction in fuel costs, according to Quatenus.

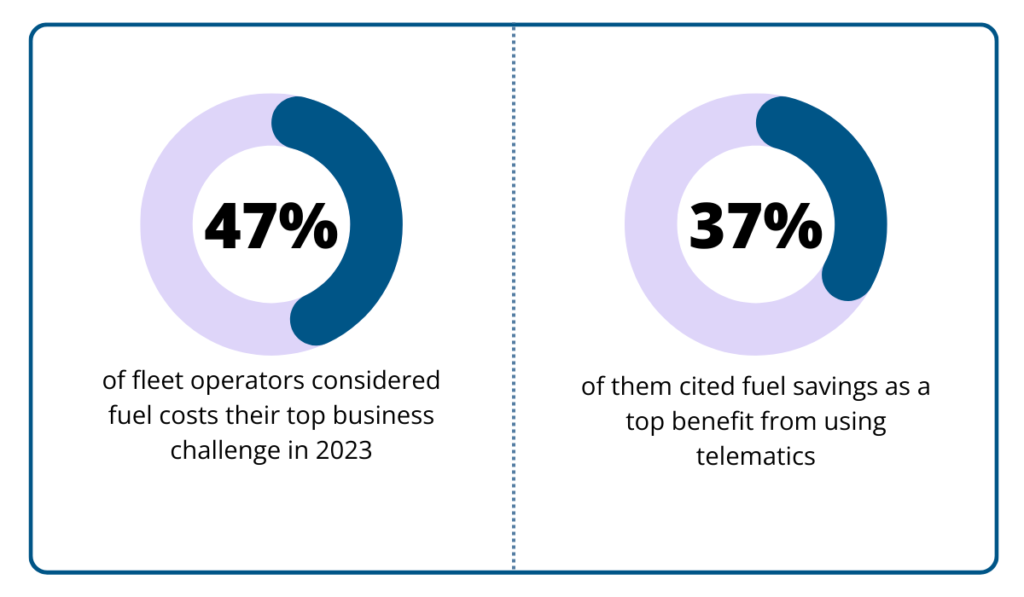

Moreover, many fleet operators cite fuel savings as the top benefit of using telematics systems.

Illustration GoCodes Asset Tracking / Data: Teletrac Navman

For instance, GoCodes Asset Tracking’ telematics solutions combine GPS tracking with vehicle sensors to monitor fuel consumption patterns in real time.

The system can track various fuel-related metrics, including consumption rates, idling time, and driver behaviors that impact fuel efficiency.

Source: GoCodes Asset Tracking

Through our fleet management software’s reporting features, managers can easily identify fuel-wasting practices and implement data-driven strategies to reduce costs.

On top of that, proper vehicle maintenance – especially tire pressure monitoring and regular engine tune-ups – can greatly improve fuel efficiency.

When you combine driver training with systematic maintenance tracking, the impact on both fuel consumption and overall fleet costs can be transformative.

These improvements deliver benefits beyond the bottom line.

By reducing fuel consumption through better maintenance and driving practices, companies can also significantly decrease their carbon footprint.

It’s a win-win approach that delivers both financial and ecological benefits.

As Uber points out, “Sustainability isn’t a buzzword or a trend; it’s here to stay and it’s a team sport.”

This highlights how modern fleet management isn’t just about cost savings – it’s increasingly about environmental stewardship and sustainability.

Conduct Regular Preventive Maintenance

Preventive maintenance isn’t just about avoiding breakdowns – it’s about maximizing vehicle lifespan and optimizing performance.

Reactive maintenance is always more expensive than preventive maintenance.

That’s because when dealing with a breakdown, you’re not just paying for repairs – you’re losing money on downtime, missed deliveries, and potentially damaged customer relationships.

As Scott Bolt, maintenance expert and vice president of product management for Noregon Systems, explains:

“The next step of the evolution is that we start doing prediction based off of use… Then, the final phase is maintaining the vehicle so it doesn’t break. Today, we’re in the fix-it-because-it’s-broke phase.”

Modern fleet management systems have revolutionized maintenance scheduling.

They do that by:

- Tracking vehicle usage and maintenance histories

- Predicting potential failures before they occur

- Automating maintenance schedules based on actual usage

- Monitoring vehicle health through real-time diagnostics

Modern telematics solutions are transforming how companies approach preventive maintenance.

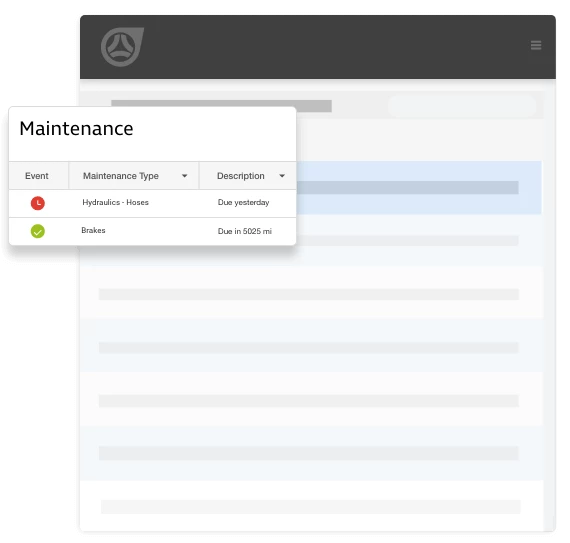

The system can be configured to automatically generate alerts based on predefined criteria such as engine hours or mileage, ensuring maintenance is performed at optimal intervals.

When integrated with fleet management software, managers receive automated notifications when vehicles reach specified maintenance thresholds, accompanied by detailed data about engine performance, fuel consumption, and other diagnostic indicators.

Source: Teletrac Navman AU

This all-around approach to maintenance tracking has helped construction companies reduce unplanned downtime, extend equipment lifespan, and ensure compliance with manufacturer warranty requirements.

By detecting potential issues before they escalate into major problems fleet managers take immediate corrective action rather than waiting for equipment failure or scheduled inspections.

Enhance Driver Training

Driver behavior directly impacts fleet performance, safety, and operational costs.

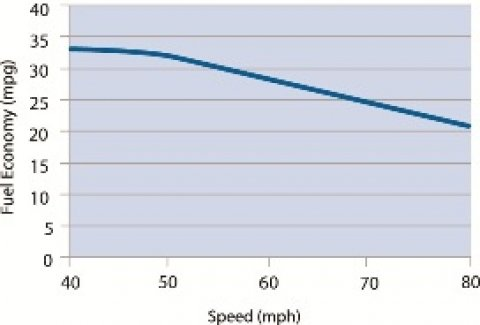

Namely, the U.S. Department of Energy has found that aggressive driving behaviors like rapid acceleration and braking can lower fuel economy by 15-30% at highway speeds.

Source: Department of Energy

By using telematics data, companies can identify and correct these behaviors through targeted driver training. And of course, achieve substantial savings in their fleets.

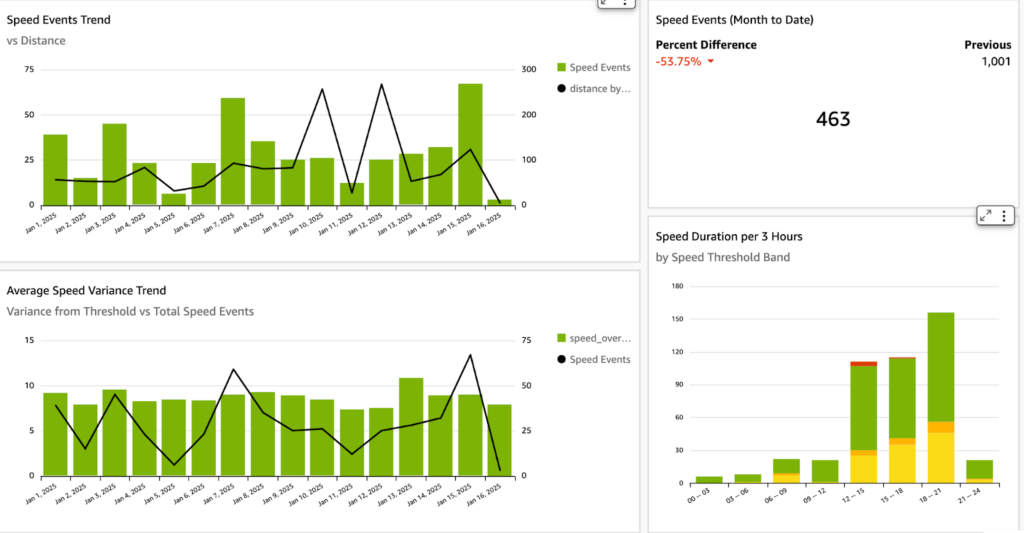

Through a combination of GPS tracking and vehicle sensors connected to software, fleet managers can track everything from speed patterns and harsh braking to acceleration rates and idle times.

The system’s real-time alerts and detailed reporting features help identify areas where drivers need additional training or support.

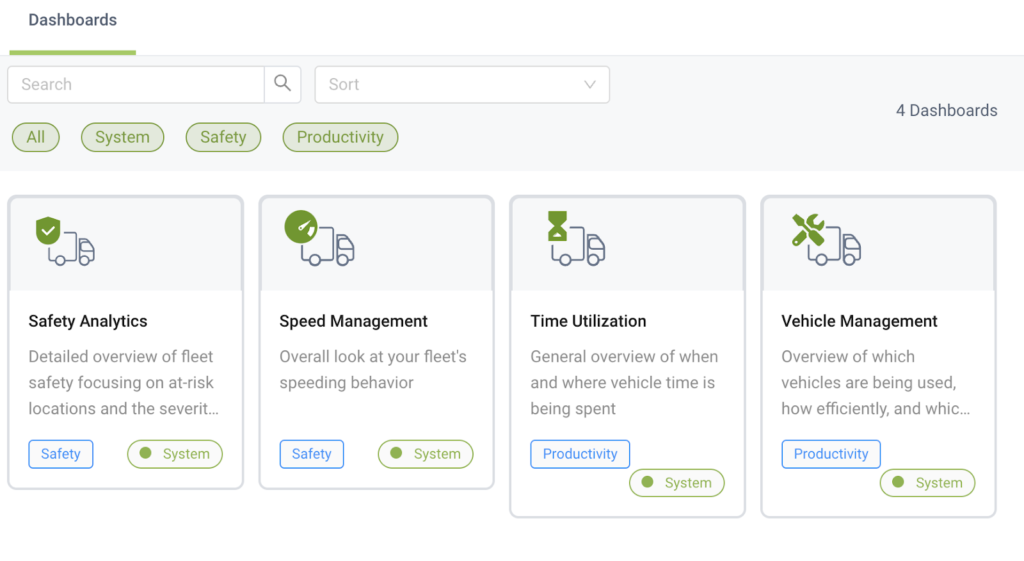

Source: GoCodes Asset Tracking

Through the intuitive dashboard, managers can easily analyze driver performance trends, set benchmarks for improvement, and implement data-driven training programs that enhance both safety and efficiency.

Source: GoCodes Asset Tracking

The most effective driver training programs are those based on actual performance data.

When drivers see their own metrics and understand how their behavior affects vehicle performance and safety, they’re much more likely to make lasting improvements.

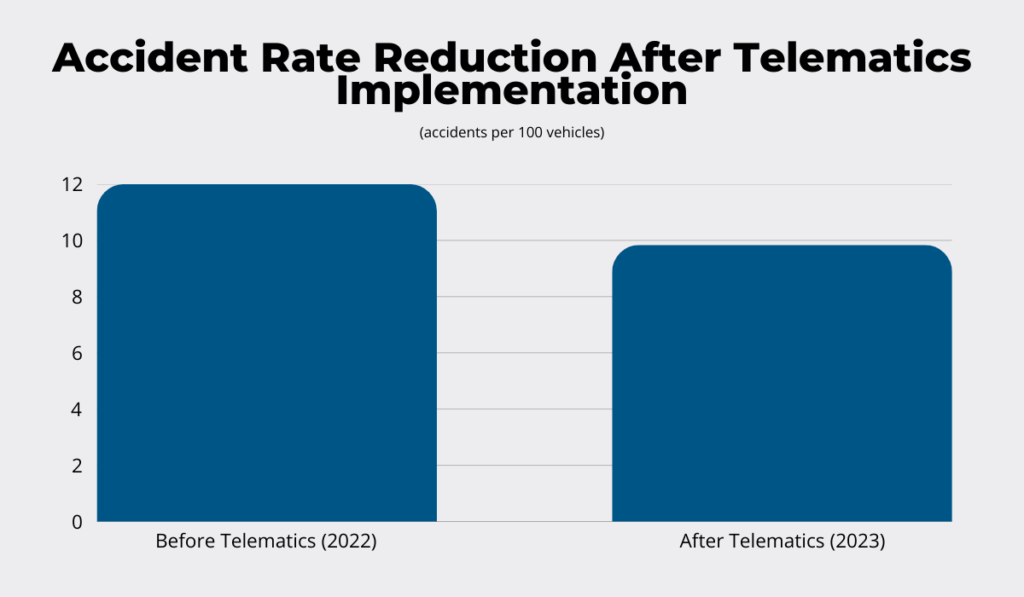

And of course, better-skilled drivers who have undergone training are less likely to cause accidents – this means no more wear and tear, and higher insurance premiums.

Today, successful companies are using telematics systems to:

- Monitor real-time driver behavior

- Track acceleration, braking, and cornering patterns

- Identify areas for improvement through data analysis

- Provide targeted training based on individual driver metrics

For instance, Ryder Europe implemented a comprehensive driver training program based on telematics data, resulting in an 18% accident reduction.

Source: Ryder

This success story led to others, and now, many more companies are using telematics to keep their drivers at the top of their game.

Analyze Total Cost of Ownership for Vehicles

Understanding the total cost of ownership (TCO) for fleet vehicles goes far beyond the initial purchase price.

Maintenance, fuel, and depreciation play a major role in a fleet vehicle’s TCO.

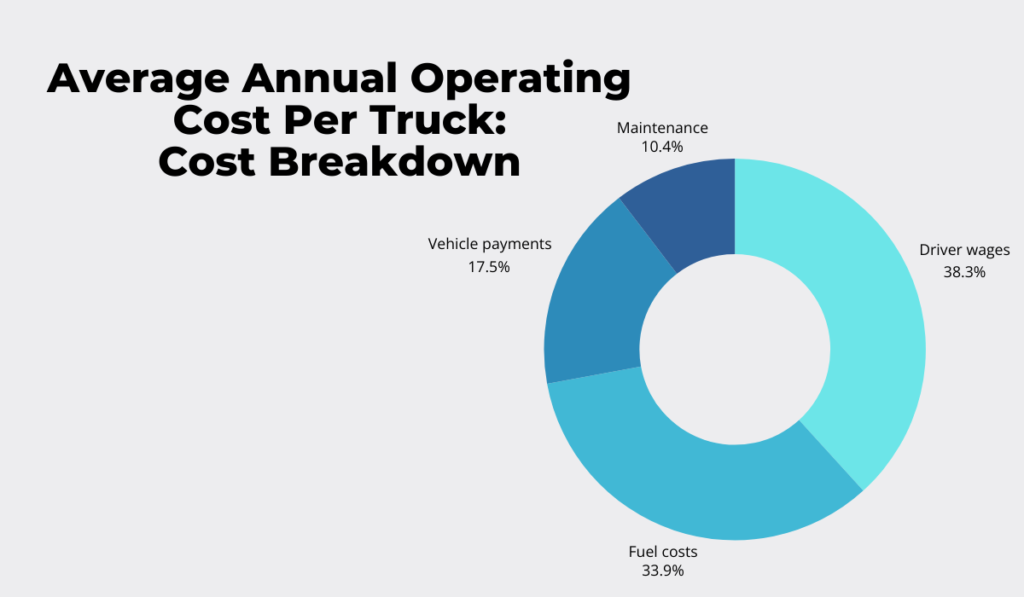

According to the American Transportation Research Institute’s 2023 analysis (via TruckingDive), the average annual operating cost per truck is now over $2 per mile.

These record costs include fuel (64.1 cents per mile), driver wages (72.4 cents per mile), truck and trailer payments (33.1 cents per mile), and maintenance costs (19.6 cents per mile).

Source: truckingresearch

But this cost is not a given – it can be improved to save large amounts of money in the long run.

This is another area where real-time tracking with telematics helps.

Smart telematics lets companies track key metrics like fuel efficiency, maintenance costs, and vehicle utilization rates in real time.

This data-driven approach helps fleet managers make informed decisions about vehicle replacement timing, maintenance scheduling, and resource allocation – all crucial factors in reducing the TCO.

Streamline Workforce Management

Effective workforce management is crucial for better fleet performance, impacting everything from operational efficiency to compliance.

A 2022 study by Harvard Business Review revealed that companies that adopted analytics-driven workforce management strategies experienced an average savings of 15% in labor costs and improved overall efficiency.

Source: GoCodes Asset Tracking

Successful fleet operations achieve this through:

- Automated scheduling systems that optimize driver assignments

- Real-time tracking of driver hours and compliance requirements

- Integration of maintenance schedules with driver availability

- Performance monitoring and incentive programs

A great example is how UPS optimized its workforce management using integrated telematics and scheduling systems.

They reduced overtime hours by one million in the third quarter from the plan’s inception, and improved driver dispatch timeliness by 13%.

As competition grows fiercer and operational costs continue to rise, it’s crucial to consider doing the same.

Conclusion

Building a high-performing fleet combines smart technology, data-driven insights, and strategic thinking.

We’ve explored how various strategies – from route optimization and fuel management to preventive maintenance – can work together to boost your fleet’s efficiency.

Start with the area that will make the biggest impact, then build from there.

Even small changes in maintenance tracking or fuel monitoring can lead to significant savings over time.

GoCodes Asset Tracking’ fleet management solutions can help you take these first steps, offering everything from GPS tracking and telematics to user-friendly software that grows with your needs.

Ready to start optimizing your fleet performance?

Explore how GoCodes Asset Tracking’ smart tracking solutions can help streamline your operations and boost your bottom line.