As a business owner in the construction industry, you know that having the right materials and supplies on hand is essential for meeting project deadlines and keeping your clients satisfied.

However, keeping track of inventory can be a daunting task when there are multiple materials, vendors, and construction sites to manage.

This is where inventory control systems come in. They are technology solutions that track materials and supplies in your inventory through software and apps.

With automated tracking, they can help you reduce waste, minimize inventory costs, and maximize profitability.

In this article, we’ll explore the five main reasons why you should use inventory control systems to stay ahead of the game in the construction industry.

Let’s start.

In this article...

Eliminates Human Error During Data Entry

First reason to implement an inventory control system in your construction company is to eliminate human error.

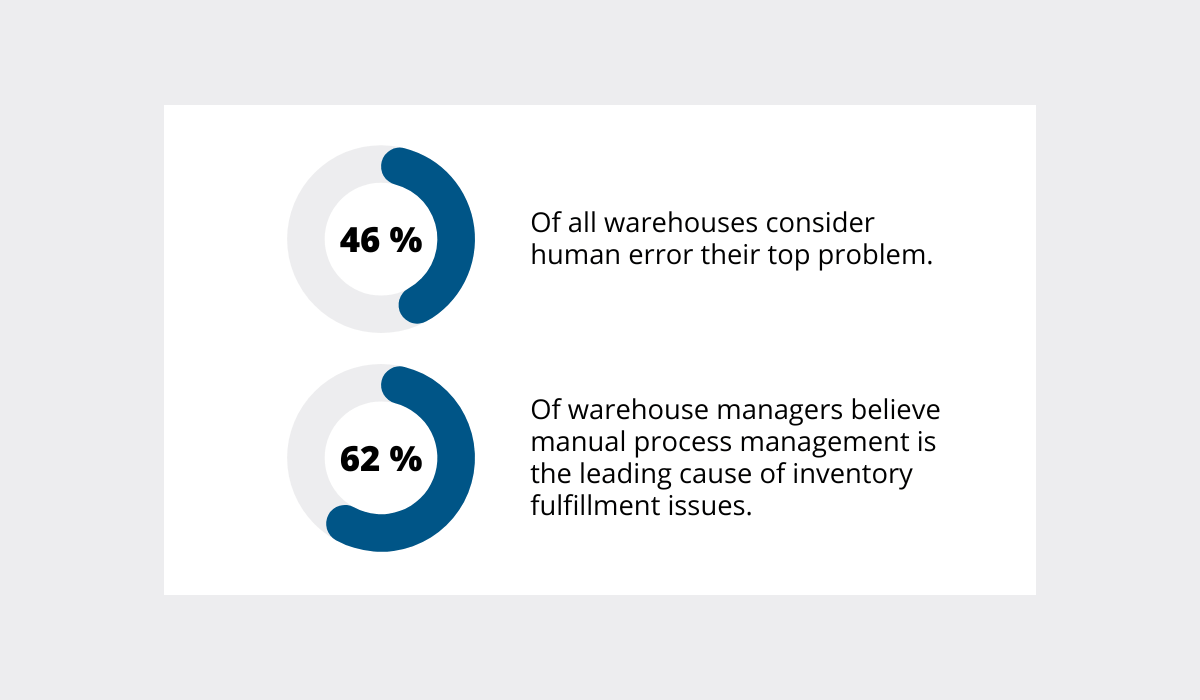

Did you know that 46% of all warehouses consider human error their top problem?

Also, according to a Stitch Labs survey, a whopping 62% of warehouse managers believe manual data entry causes the most issues in inventory tracking.

These staggering statistics highlight the need for automation and technology in inventory management, especially in the fast-paced and demanding construction industry.

When we count items, and when the amount of items is large, it is easy to lose track of counting, skip an item, or count it twice.

And if this happens and you have incorrect data about your inventory levels, you can experience significant setbacks for your company.

However, these mistakes can be avoided with the inventory control system because it works on the principle of automation.

That means the process will not require entering data into the system manually. Instead, it will be done automatically by scanning the barcode tags on inventory items.

Moreover, barcode inventory control systems offer more than just a solution for innocent human errors during counting. While those errors can be corrected and forgotten, the system also addresses more serious issues like theft and fraud.

Unlike manual data entry, the system’s barcode automation makes it virtually impossible to enter incorrect information, significantly reducing the risk of theft and fraud.

This means that construction companies can rest easy knowing that their inventory is secure and their profits are protected.

Let’s learn how the barcode inventory control system works.

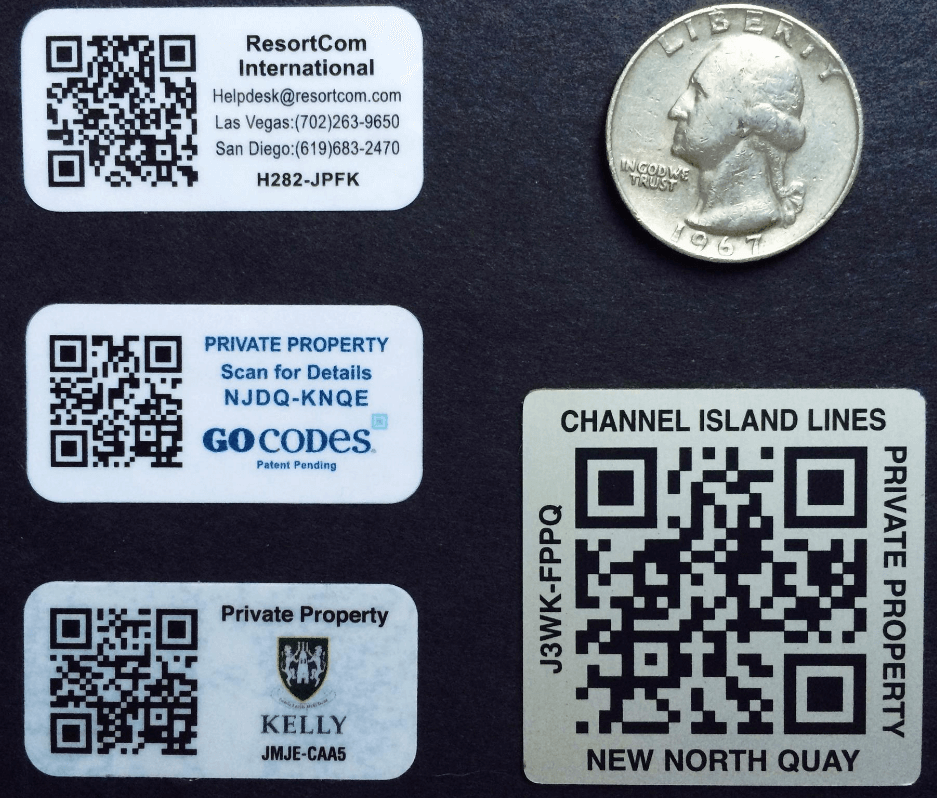

First of all, the system is easy to use. Each item in the inventory is assigned a unique barcode or quick response (QR) code, and the sticker is attached.

You can see an example of a QR code in the image below.

These codes are then scanned using a handheld scanner or, in the case of systems like our own solution, GoCodes Asset Tracking, smartphone scanner apps, which you can see on the right side of the photo.

Once scanned, the information is instantly uploaded into the inventory management software.

QR codes are customizable and allow you to decide what information you will put on the labels.

That gives you an even broader spectrum of optimizing your inventory tracking, making it personalized.

In the photo below, you can see some examples of what various QR codes look like.

To sum up, investing in a sound inventory control system will automate your inventory tracking, minimize human errors and prevent fraud and theft of your inventory—all the more when you will have customizable labels made only for your company.

Tracks Inventory Quantities in Real-Time

Knowing real-time inventory levels is crucial in the construction industry because it enables decision-makers to manage projects more efficiently and effectively, reducing delays and increasing productivity.

For example, if your construction company runs out of a critical material like cement, it could face project delays and additional costs.

With an awareness of real-time inventory levels, you can anticipate the need for more cement and order it before it runs out.

This ensures that the project continues without interruptions, and you avoid the cost and time associated with stopping and restarting a project.

Our asset and inventory tracking software, GoCodes Asset Tracking, has a feature that allows you to track consumable inventory using our scanner apps.

Let’s see how it works.

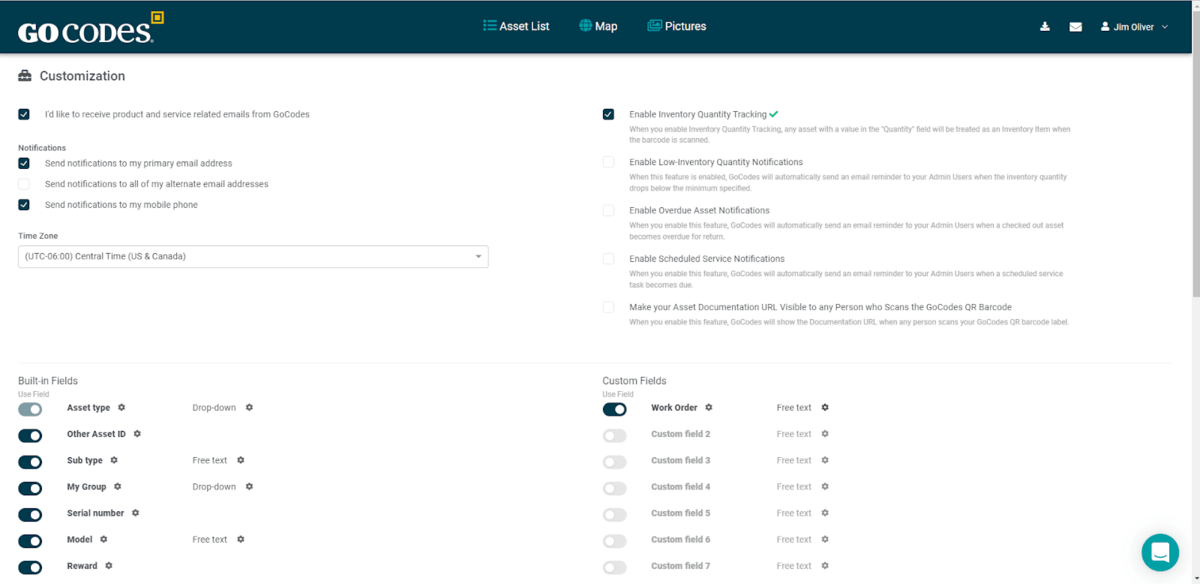

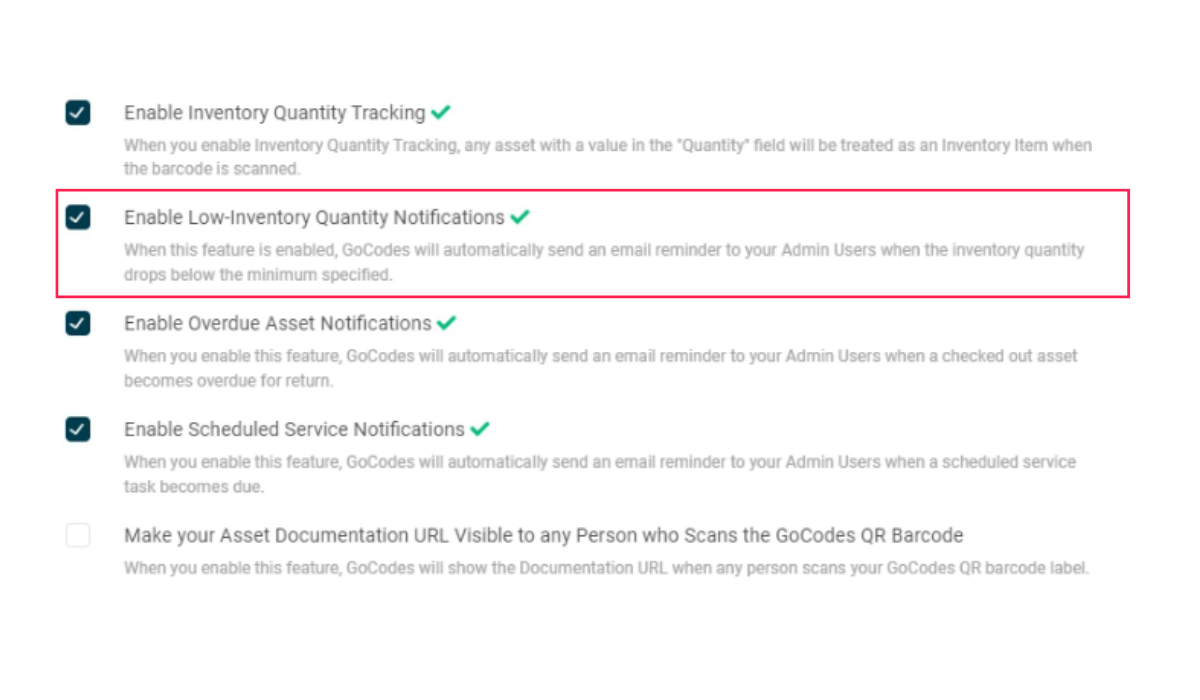

The first step is customizing your GoCodes Asset Tracking account. You can do that by clicking on your name in the upper right corner and scrolling down to the Customization section.

Once you do that, check the Enable Inventory Quantity Tracking checkbox, which you can find at the top right of the Customization screen, as seen in the image.

When you have enabled the feature, go back to your asset list, and you are ready to start tracking your inventory.

You can also use our mobile app to track inventory quantities. First, you must enable the Quantity check in the Customization section on your computer.

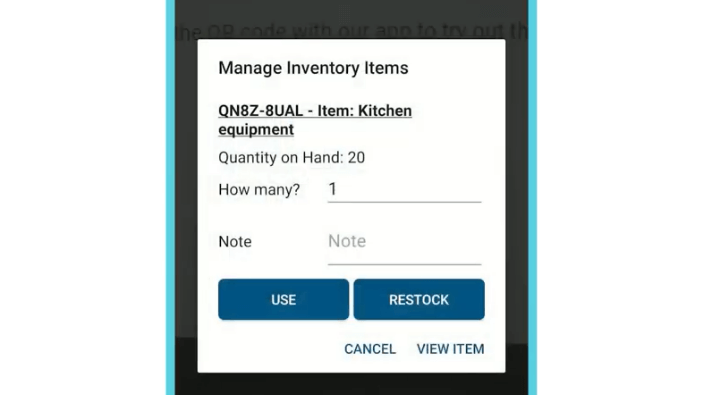

When you scan a QR code attached to an item with an app, a new window will appear with information about the item.

You will have options on what to do with the thing, such as use or restock.

When you, for example, use more of the same items and you go back to the main page, you will see that the quantity information was updated to the actual number of things that are still available.

Also, in the history tab, you will see the location, quantity, and time of the scanning and have all information in one place.

In GoCodes Asset Tracking, everything is automatic, and you know when and where your inventory is used in real-time.

Check the video below to learn how to use the GoCodes Asset Tracking tracking inventory quantity feature in detail.

To finish off, by having a real-time picture of inventory levels, you can make informed decisions about purchasing, production, and delivery, leading to more streamlined operations and increased profitability.

Shows When to Order New Inventory

A sound inventory control system will notify you when the quantity of a specific inventory item reaches or falls below the minimum and alert you when to order new inventory.

This is possible because inventory control systems use data analysis and forecasting techniques to determine when a product is likely to run out.

When your inventory quantity value falls or is under the minimum value that you have set, the system will alert you to order more before it becomes a problem.

This is usually done by email reminders or by notifications inside the app.

The photo below shows how such a feature looks in the inventory tracking software.

How does this work in practice?

Imagine working on a massive construction project tasked with building a steel bridge that will be used by thousands of people daily. It’s a high-pressure job, and you’re determined to complete it on time and budget.

But then disaster strikes. On the day of installation, you realize that your construction company is running low on steel beams.

Panic sets in as you know this could result in costly delays, additional labor expenses, equipment rental fees, and penalties for not meeting the project deadlines.

Luckily, you have a secret weapon: an advanced inventory control system that alerts you when the stock of critical materials is running low.

Thanks to this system, you receive an early warning that you need to order more steel beams before they run out.

By taking action quickly, you’re able to prevent a major setback in the project and keep everything on track.

So when choosing the right inventory control system for your company, make sure to select the one with a feature that will alert you about low quantities in your inventory.

To sum up, your company can reduce stockout risk and improve operational efficiency by having real-time alerts on inventory levels.

Reduces the Risk of Inventory Shortages

The inventory control system’s ability to reduce the risks of inventory shortages is another excellent reason why you should start using it.

When inventory shortages occur, they can have significant impacts on construction companies, including project delays, increased costs, and, consequently, unhappy clients.

For example, research from the Capgemini Research Institute has shown that the shortage of critical parts and materials increases project costs by striking 74%.

Such a large percentage is dangerous and can easily harm your company’s profits.

Let’s return to our steel beams example to see how inventory shortage impacts your business.

Now imagine that you didn’t correctly track your inventory and failed to notice that you are running low on steel beams. The day of installation came, but you didn’t have enough material.

To remedy the situation, you had to rush order the missing steel beams, paying a premium price for expedited shipping.

The additional cost of the rushed order and the labor costs for the delay resulted in increased expenses, cutting your profits.

Moreover, the delay meant that the project was not completed on time, causing further inconvenience to the client and potentially damaging your company’s reputation.

In this example, the inventory shortage led to a delay in the project, which resulted in increased costs and an unhappy client.

If you had an inventory control system in place, you could have easily avoided this situation by receiving timely alerts when inventory levels were low, as explained in the previous section, and taking appropriate measures to prevent shortages.

The photo below shows a simple equation that will help you visualize the factors affected by inventory shortages.

As you can see, the equation is pretty simple. It implies that eliminating shortages means avoiding delays and extra costs and getting happy clients.

Overall, inventory shortages are a significant challenge for the construction industry and can seriously affect project timelines and budgets.

That’s why an effective inventory control and tracking system is essential for construction companies to stay on top of their inventory levels and prevent shortages.

Makes It Easy to Perform Inventory Audits

In addition to the four reasons we listed in the previous sections, the inventory control system also simplifies inventory audits.

By attaching barcode tags to inventory items, an inventory control system allows quick scanning with a built-in barcode scanner.

Information about the item’s location, the date and time of scanning, and the identity of the person who scanned the item will all be visible in the system.

Barcode scanning eliminates the need for manual data entry during the physical counting process of auditing.

Inventory items are quickly and accurately identified and recorded in the inventory control system.

This is a huge time saver and reduces the risk of errors that can occur with manual data entry.

Moreover, barcode scanning can help identify discrepancies between physical and recorded counts in the inventory control system.

By scanning each item, the system can compare the recorded count with the physical count, making it easier to identify discrepancies and address them promptly.

However, when choosing the inventory control system for your company, you should consider the one with the audit feature with the option to scan multiple barcodes simultaneously.

This will make the auditing less time-consuming and the person performing the audit can handle it in bulk instead of doing everything at once.

To summarize, an inventory control system can streamline inventory auditing, making it easier to identify and address discrepancies and optimize inventory management processes.

Conclusion

Investing in an inventory control system for your construction business is a no-brainer.

By eliminating human error during data entry and tracking inventory quantities in real-time, you can streamline your operations and keep your projects running smoothly.

Moreover, the inventory control system will prevent you from having additional costs and unsatisfied clients by alerting you when to order new inventory reducing the risk of inventory shortages.

With the help of this technology, you’ll be able to manage your inventory more efficiently, save time and money, and ultimately grow your business.

Start exploring inventory control systems today and take your construction business to the next level.