Contractors are responsible for a vast array of activities during a project.

These can range from tedious permit-related paperwork to the brute digging work of heavy machinery and the fine craftsmanship only a master plasterer can provide.

A good project manager balances all these activities, and while they might not be an expert at every single one of them, they should know what to look for in an inspection and understand the skills of the employees who provide these services.

This is particularly true of those activities that take place on the construction site itself.

Broadly, the main types of construction activities are site marking, excavating, welding, concreting, brick masonry, and plastering.

In this article...

Site Marking

Site marking is one of the first exciting signs that a construction project has progressed from the planning stage to the actual execution.

Marking the construction site is one of the activities to undertake before the rest of the project gets underway.

Site marking involves setting reference points for the approved plan boundaries in the form of construction grid lines. Here is an example of a grid layout:

As you can see, these boundaries are marked and the dimensions of the site are carefully measured.

These lines provide team members with a common point of reference on the site, as well as a way to orient themselves according to the planned layout of the project.

Excavating

Excavating breaks the ground and truly begins the physical phase of the project.

It includes the removal of soil, rocks, and tree roots to prepare for building foundations or specialized landscaping.

Sometimes particularly deep excavation takes place to prepare an area for putting in the foundations of a building, or an underground basement.

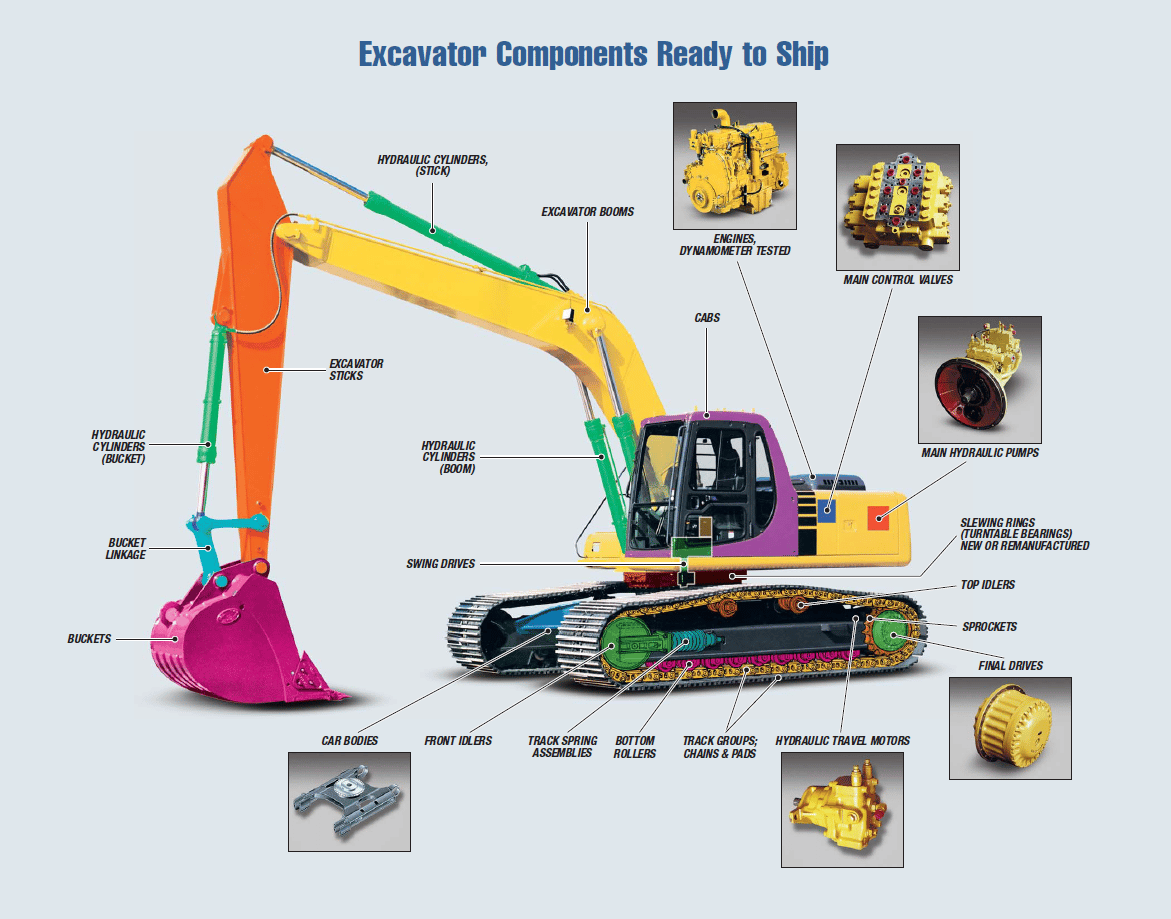

Excavation is often achieved with specialized heavy equipment called excavators. Excavators are massive treaded machines designed to claw, lift, and move heavy loads of earth.

The visual aid below shows the many components of a standard excavator.

This picture gives an idea of the complexity of an excavator, and the power it requires to safely prepare the ground for the other team members.

The depth to which the excavators work is usually determined by site plans and a soil investigation report.

If the dig is particularly deep, the foreman usually calls for inserting supports for the walls until the foundation is complete.

Excavation is so important and complex that the construction industry divides it into various types, based on several different factors.

Material is one of those factors:

- Topsoil: The uppermost layer of soil, plus vegetation, grass, trees, or leaf piles. Removing the topsoil, even on a site that will not contain a foundation or a basement, helps to ensure that the land can support the weight of the building.

- Rocks: On most sites, rocks will be relatively small in size, but project managers should budget time and resources for clearing away particularly large rock formations. Sometimes this involves blasting or drilling, which have to be done by specialized contractors.

- Muck (mud): This messy mixture of water and dirt is a construction nightmare and must be removed through excavation before the foundation is poured.

- Earth: This refers to all of the soil beneath the topsoil layer.

We can also categorize the types of excavating according to purpose:

- Cut and Fill: When a plot is large and does not require the removal of large rocks, this technique is used to clear away upper layers of topsoil and sand. The construction area is also graded.

- Trench: Usually relied upon to prepare the site for such utilities as pipes, sewer lines, or gas, narrow channels are dug to clear away obstructions and allow for deeper work.

- Basement: Non-sandy soil areas above the water table are typically suitable for basement excavation. This prepares the site for construction below ground level.

- Dredging: When there is a body of water at the jobsite, dredging takes place to remove sediment, trash, and animal debris so that the land underneath is suitable for allowing boat passage or drilling for supports.

Excavation can quickly become expensive if unwelcome discoveries are made once it starts, or if substandard weather conditions plague the build.

A wise project manager plans for these hindrances and finds ways to overcome them.

Welding

Welding is a trade skill done by specialized craftsmen that entails creating structurally sound metal frameworks by joining various metal components with seams of heat, most notably joints in large buildings.

In construction, it is also used to construct joists in flooring, staircases, handrails, and firewalls.

The American Welding Society notes that welding craftsmen are currently in short supply, and the shrinking pool of certified welders means that the US will experience a shortage of 400,000 welders by 2024.

Their lack of availability could delay projects and raise labor costs, as it is estimated that about 50% of all products in the United States are welded.

Welding is so widespread because it offers many benefits compared to other techniques.

It helps to ensure structural integrity, especially in tall buildings that will support a great deal of weight.

Moreover, it improves the durability of the heavy equipment employed at construction sites.

As technology advances, welding is also becoming increasingly efficient and productive.

This technique is extremely flexible, so it is applicable both in small personal home projects and large-scale public ones.

Concreting

Most construction projects involve the use of concrete at some point.

The material has a wide variety of applications and can be used for the base of buildings, roads, bridges, and much more.

Concreting is the process of mixing and applying a mixture of water, sand, and gravel to form a substance that hardens when it dries. Shale and limestone are used as well.

The graphic below indicates how indispensable concrete is in the construction industry.

In fact, concrete is the most used building material in the world. Each year, six billion tons of concrete are mixed and poured in construction projects.

It is an inert substance that is easily made in large quantities, which contributes to its popularity.

Moreover, it’s economical compared to other building materials.

It hardens quickly in a fairly wide variety of weather conditions, and the amount of energy required to produce it is remarkably low.

In a liquid state, concrete is easily poured into molds, and when it hardens, it provides strong resistance to high temperatures.

Finally, once concreting is complete, it can last a long time, particularly when reinforced with rebar.

Brick Masonry

Brick masonry, or the laying of bricks in a systematic way, ensures that the building will have structural integrity.

Bricks are placed in and bound with mortar—for example, cement mortar—and are left to dry.

Offset bricklaying involves interlocking patterns so that cracks remain contained within a single brick rather than expanding throughout the entire wall.

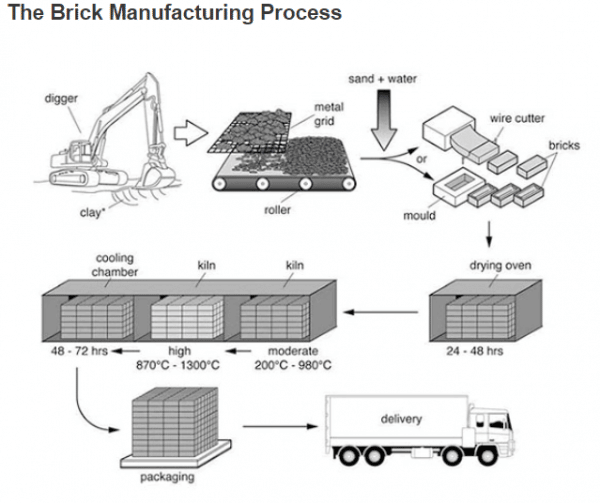

As the graphic above shows, brick-making is long, complicated, and labor-intensive. However, the process of supplying specialized bricks can take even longer.

While most people might associate this material exclusively with red or light-covered clay bricks used in houses, many more types are used in construction.

Here are just three:

- Engineering Bricks: These bricks are also made of clay, but they are harder than typical bricks, and therefore less porous, so they are typically used for paving.

- Silica Bricks: Bricks made from silica (sand) can withstand extremely high temperatures, and are commonly used in the construction of chimneys. A small amount of lime is included in silica bricks as a binder.

- Acid Resistant Bricks: Clay is also present in these bricks, but they also include silica and feldspar, which contains large amounts of calcium, sodium, or potassium. They are usually made in chemical plants.

Bricks are cheaper than stone, and they are relatively lightweight.

A brick wall is usually durable and fireproof. However, bricks are not suitable for earthquake zones and tend to take on water more than other surfaces.

Plastering

Plastering is the process of covering masonry and blockwork with plaster, which is a mixture of cement and sand with the required amount of water.

Although plaster is sometimes less aesthetically pleasing than brick, it is often used to protect walls from elements that can damage them.

Plaster is available in a number of different forms, including lime, gypsum, cement, and clay. Specialized plasters can also aid in waterproofing.

Construction teams use internal or external plastering in a project. As the name suggests, internal plastering is placed on walls facing the indoor side of a building.

It provides fire protection and a certain amount of insulation.

External plastering, on the other hand, is applied to outdoor-facing walls. The form of plaster used there is made of cement and sand.

Workers spread it over blockwork or bricks. The plaster acts as additional protection from the elements and dries to a coarse finish.

This photo shows external plastering in progress. It is accomplished with scaffolding and covers the appearance of the concrete:

Although plastering offers protective qualities, it is typically considered part of the finishing process in a build.

Plastering can affect the aesthetics of a completed structure, and it usually signals that the project is in its final stages.

Conclusion

Paying attention to the various stages of construction invites project managers to have a better knowledge of how one phase of the project can affect another.

Site marking, excavating, welding, concreting, brick masonry, and plastering all provide significant signposts on the progression of a construction project.

Learning more about these construction activities and how they are intertwined can also present opportunities for improvement, which will eventually boost the efficiency and productivity of the entire project.