Customers often ask us how to barcode their assets. Their goal is to be able to uniquely identify each asset with a secure barcode so that they can accurately track it throughout it’s’ life. In many cases, these assets have a lifespan spanning many years, so it’s important that the barcode labels be securely attached, remain legible and withstand their operating environment.

In this article...

Part of a barcode solution

In most cases, barcode labels or tags form part of a larger solution that is used to track the assets. In many cases, companies purchase hardware, software or hybrid solution from a vendor and then contract with a label manufacturing company to create barcode labels which are compatible with the system they purchased. Customers are often surprised to learn that these labels can be quite costly vs. paper labels due to the desired longevity and operating environment they are designed for. In effect the customer acts as the system integrator as they install the software, setup the hardware and procure or print their barcode labels to create a complete system. We find that many customers would rather purchase a complete solution from a single vendor, one that includes custom barcode labels.

Sourcing the labels/tags

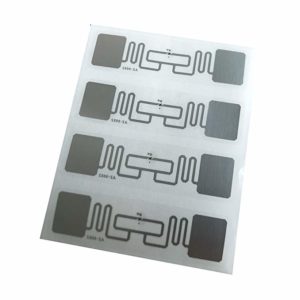

Once a decision is made in terms of the overall solution, the labels can be designed and procured from a vendor. When ordering, customers are asked to specify the following common parameters specific to their application: quantity, material, adhesive spec., dimensions, barcode type, color, logo or design options. The most common options are to use a polyester or polycarbonate label which may also be laminated to increase the overall resilience. 2 x 1 inch is a common size, and utilizes a linear 1D barcode (looks like stripes). Most labels include rounded corners and a permanent adhesive which requires up to 72 hours to cure.

Common application requirements

When applying the labels, it’s often necessary to apply pressure to trigger the adhesive curing process. Also, we recommend that the surface be completely flat, smooth and clean. In many cases it’s recommended that the surface be cleaned with a degreaser to ensure a strong bond.

Using spreadsheets

Some companies choose the simplest solution which is to record the assets information by serial number (from the barcode) in a spreadsheet. This approach has limitations in the long run. In many cases, the data quickly atrophies as assets are never consistently updated.

Next steps

Overall, the key to successful asset barcoding is to implement a complete solution that includes all the components required and is easy to use, so the data is easy to maintain going forward. It may have to span many years and changes in ownership etc.

Looking for more information? We are always ready to help answer your questions.

Other Articles You May Like

How to Choose the Best Inventory Software for Your Business

What should I print on my asset labels?

Get Tough on Asset Management! – Rugged Solutions for Apple iPad and Android Tablets

The real reason SMBs switch to cloud apps [INFOGRAPHIC]