Key Takeaways:

- Active instrument tracking enhances patients’ safety and operational efficiency,

- Poor-quality solutions do more harm than good.

- Metal tags are the best choice for instruments exposed to frequent autoclaving.

- QR code labels and RFID tags can be combined to deliver optimal tracking results.

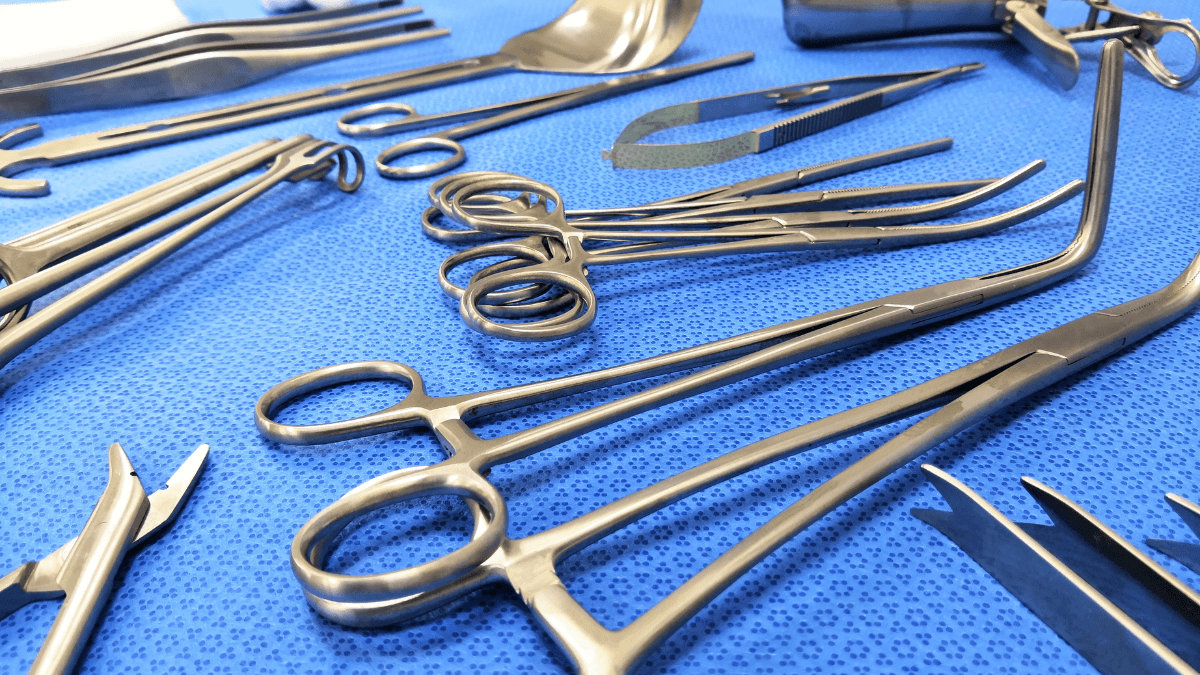

Surgical instruments are a staple of modern healthcare.

Any misplaced instrument or contamination has a profound impact on patient care and outcomes.

Since keeping track of this key inventory can mean the difference between life and death, healthcare providers are eager to explore new solutions and tracking methods.

In this article, we’ll be focusing on the key benefits and challenges, along with best practices for tagging surgical instruments.

Curious to learn how you can ensure patients’ safety while maximizing operational efficiency?

Let’s dive right in!

In this article...

The Importance of Actively Tracking Surgical Instruments

There is no debate about the importance of tracking surgical instruments.

The traceability of these critical instruments has always been a top priority for medical equipment managers for several reasons.

The first one is ensuring patients’ safety.

Hospitals and clinics pour a lot of resources into eliminating risks and ensuring top-notch care across all departments.

However, surgical care always demands extra attention.

Even a minor surgery can prove fatal if the patient is exposed to unsterilized equipment.

And if you’re not actively tracking your medical equipment, unprocessed and potentially contaminated scissors, clamps, or retractors can easily find their way to the surgical tray.

What’s more, it’s rarely just one slip-up, as shown in the example of one hospital in Denver.

Source: CBS News

The saga ended in 2023 with a $6.5 million settlement that benefited around 3,000 patients, and hopefully led to better sterilization practices at the Porter Adventist Hospital.

The stakes are even higher during emergencies.

Let’s say you’re facing patient overflow, and you need to transfer surgery kits to ORs and ensure there are enough of them on standby.

While it’s possible to handle these situations the old-school way, this puts unnecessary strain on the staff and can further endanger patients.

In situations where every second counts, quick equipment locating makes all the difference, but the advantages also extend to broader compliance requirements.

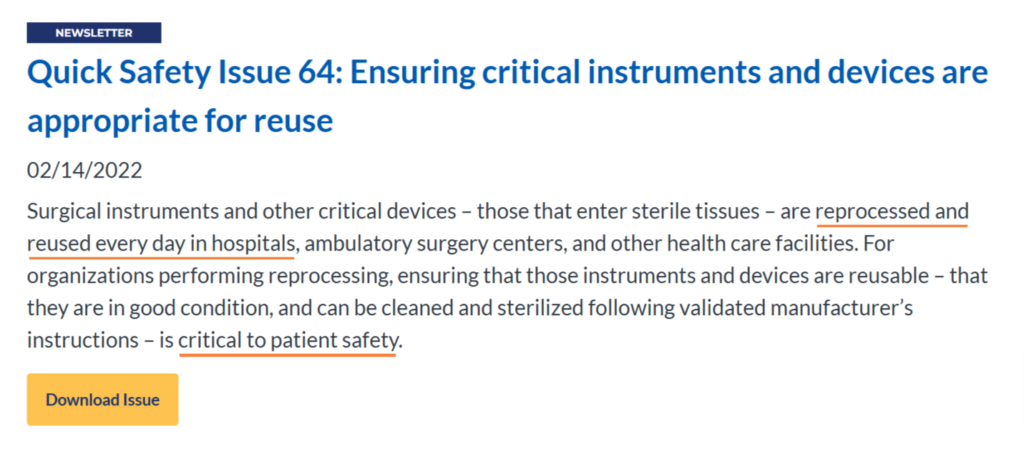

All medical facilities are subject to strict regulatory standards and audits.

For instance, healthcare providers in the United States can’t hope to secure certain accreditations without meeting The Joint Commission standards.

These extend to the reuse of surgical instruments.

Source: The Joint Commission

When you think about it, active instrument tracking benefits hospitals on several levels.

It helps prevent mistakes by identifying cases of non-compliance while at the same time making it easier to maintain records for inspections, sterilizations, and repairs.

This means that hospitals can readily provide a comprehensive record of each instrument’s history, from procurement to disposal, which is vital for audits and regulatory reporting.

Tracking surgical instruments has multiple benefits outside the ones we mentioned, from reducing costs by preventing misplacement to improving accountability among staff.

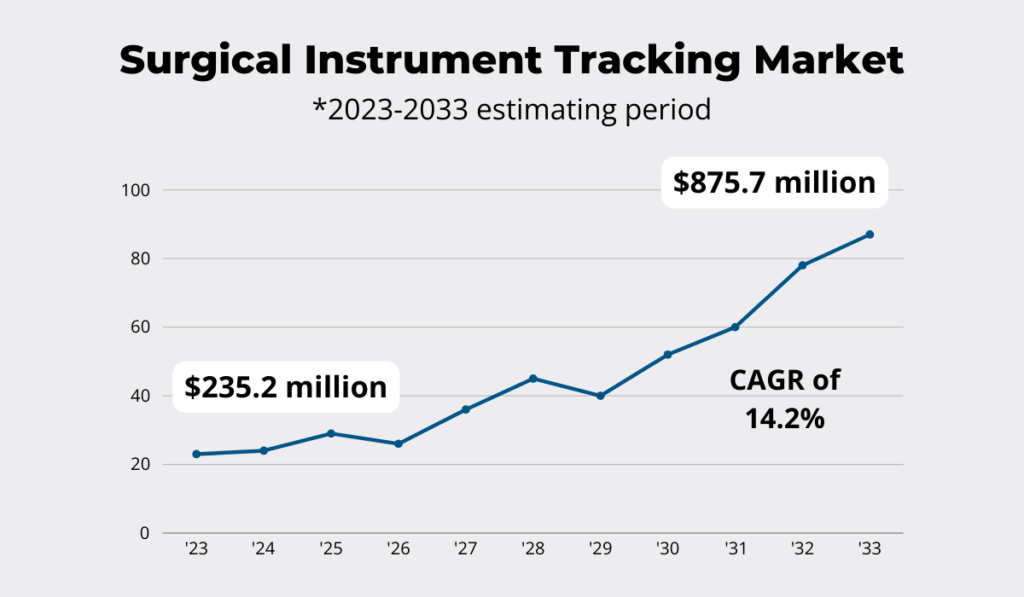

Such impact is one of the reasons why the surgical instrument tracking market was valued at $208.6 million in 2022 and is only expected to grow, as shown in the chart below.

Source: Persistence Market Research

According to the report, much of this growth can be attributed to tracking hardware such as scannable barcode labels and QR codes or RFID tags that provide seamless identification.

Still, cloud-based software is a key element, keeping all information on the surgical instruments’ location, usage, sterilization status, and maintenance schedule in one central location.

As always, choosing an asset-tracking solution depends on factors such as cost, tag durability, and operational requirements.

The one thing they have in common, however, is that they address a range of challenges related to managing surgical instruments.

Challenges in Tracking Surgical Instruments

Managing surgical equipment is a tricky affair regardless of the type and size of the healthcare facility.

Finding Suitable Labels

One of the most common challenges has to do with continuous exposure of all tools and instruments to harsh sterilization environments.

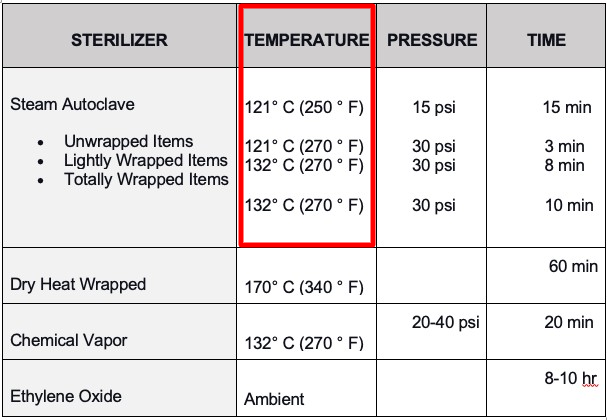

As shown in the video below, the most common method of sterilizing surgical instruments is autoclaving, a process that uses high-pressure steam to kill all harmful bacteria and viruses.

Source: World Precision Instruments on Youtube

Although some surgical instruments require cold sterilization, it’s a much lengthier process that lasts several hours.

Meanwhile, the autoclaving cycle is much more efficient and thorough, but it exposes the equipment to temperatures ranging from 250°F (121°C) and 273°F (134°C).

Source: Nevsink

Given the prolonged exposure to extremely high temperatures, the tracking labels you implement must be able to handle such conditions.

Simply put, low-quality labels and unsuitable materials won’t be able to withstand steam, and making the wrong choice here can do more harm than good.

For instance, a 2013 study of surgical instrument labeling techniques cites a body of evidence on the dangers of low-tech marking techniques.

This includes cases where a piece of tape or laminate would break off during a procedure, entering the wound and later causing infections and blockages.

Although technology advanced significantly in the past decade, it’s safe to assume that using tags with poor-quality adhesives or the wrong material would create similar problems or simply prove wasteful resource-wise.

Complex Inventory Management

Another major tracking challenge comes from the complex inventory management in medical facilities.

Inventory management involves several processes, such as:

- pharmaceutical inventory management,

- high-value equipment management,

- medical supplies reordering, and

- waste management.

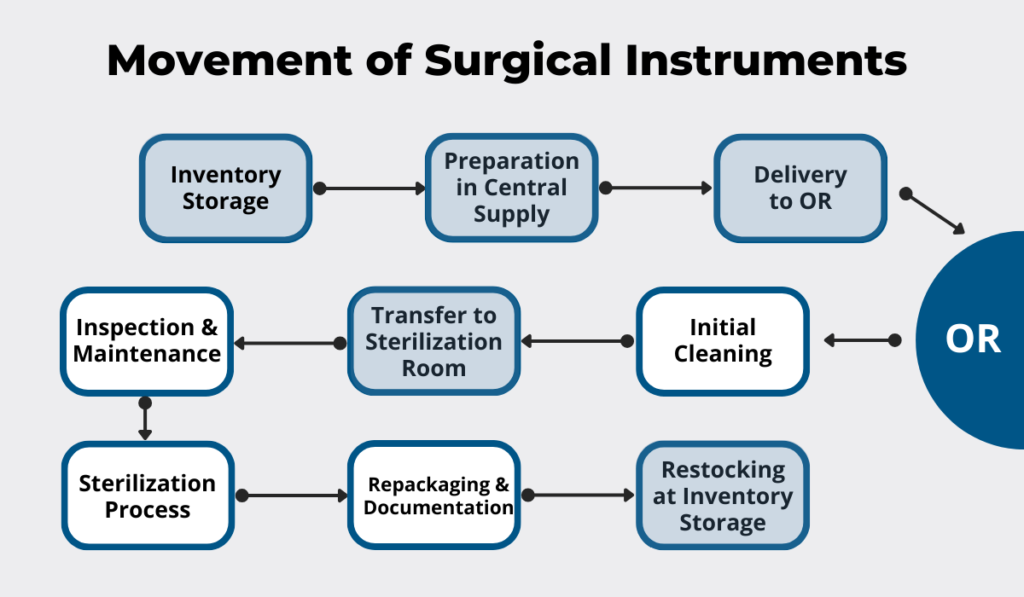

On top of all that, equipment managers need to keep track of instruments that are essential for time-sensitive surgical workflows.

The instruments require quick identification but they also move quickly between several areas within and outside the facility.

Here’s a simplified outline of such movement before and after a procedure.

Source: GoCodes Asset Tracking

That’s no less than four different areas for a single operation!

Now let’s say there is a hiccup somewhere along the way—a slight delay can create a ripple effect, impacting the quality of care and the patient’s health.

Measuring the impact of such situations is next to impossible, but several studies indicate that low traceability of instruments and delayed access can ultimately lead to loss of life.

Considering the high-stakes environment, adopting advanced tracking methods no longer feels optional.

Brent Brown, a VP and General Manager at Zebra Technologies notes that such technology is indispensable, ensuring precision in real-time.

Illustration: GoCodes Asset Tracking / Quote: Oracle

It boils down to improving workflows by capturing location and use history.

In other words, advanced tracking systems allow you to identify the tool and who used it last, check whether it needs sterilization or not, add special handling instructions, and assign it to the right OR.

Still, the overall results will depend on your choice of tag material and technology.

Why Metal Tags Are Ideal for Instrument Tracking

Metal tags are a reliable and durable solution for tracking surgical instruments in all healthcare settings.

At first glance, these aluminum foil tags don’t look that different from any other common label material, such as polyester.

Source: GoCodes Asset Tracking

However, looks can be deceiving.

The material’s properties and strong adhesive make it particularly suitable for prolonged use and the demands of ongoing sterilization.

Namely, metal tags can easily withstand:

- autoclave cycles,

- different cleaning agents, and

- heavy handling.

Since metal tags come in many shapes and sizes, it’s important to check their specifications for temperature.

| Attribute Name | Unit of Measurement | Value |

| Short Term Temperature Resistance | Minutes or Hours | 121°C (250°F) |

| Long Term Temperature Resistance | Day or Weeks | 70°C (158°F) |

Once you’ve checked the specifications, make sure you’ve picked the most wear-resistant and compatible material.

For example, stainless steel has long been used in healthcare environments where hygiene and durability are essential.

Don’t forget that there are also different processes for printing asset data.

Embossing or stamp marking is a good choice for surgical instruments, as the information on them will be less likely to fade or degrade over time compared to printed or laser-etched tags.

Precision is one additional argument in favor of metal tags.

Source: GoCodes Asset Tracking

Metal tags won’t wear nearly as fast as some other materials.

These properties also leave little room for any sort of tampering so there will be less chance for someone to manipulate inventory, conceal usage history, or steal the item.

Now that we’ve established the ideal material, let’s discuss the different technologies you can use.

Comparing QR Codes and RFID Tags

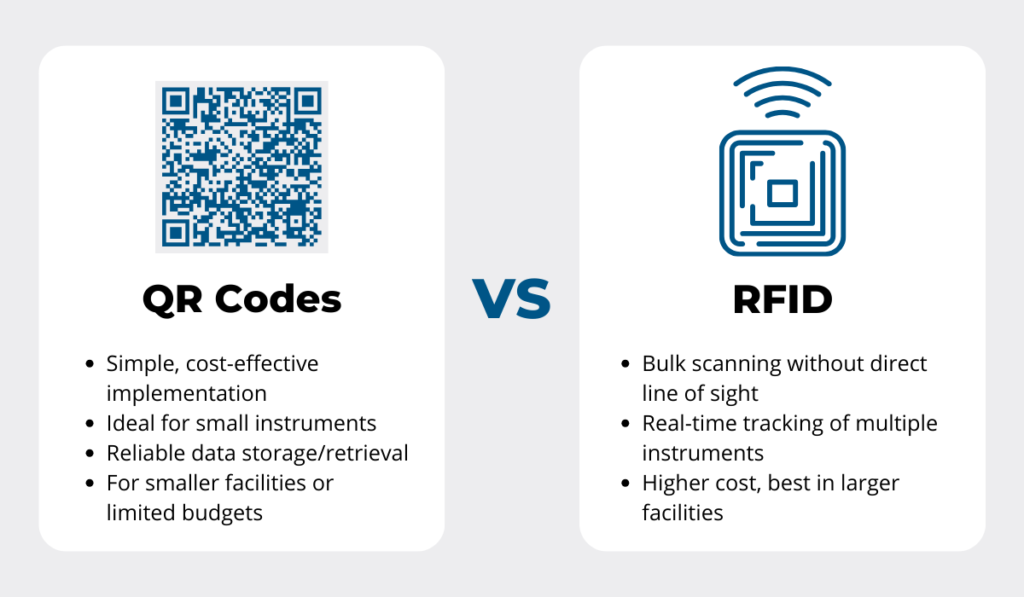

Both QR code tags and RFID tags can be used for tracking instruments in the medical sector.

However, understanding the key differences between them is essential.

First, let’s see what QR codes and RFID tags have in common:

| Compatibility with Various Materials | Used with a range of tag materials, including metal. |

| Data Scanning | Rely on scanning to retrieve information. |

| Automation & Efficiency | Streamline data collection, eliminating the need for manual record-keeping and reducing the chances of errors. |

| Wide Applicability | Used in diverse industries, from healthcare and manufacturing to logistics and retail. |

Now, let’s dive into specifics, starting with QR codes.

The biggest selling point of this tracking technology is that it’s cost-effective and easy to deploy.

Even smaller medical facilities with limited budgets can use this technology, integrating it with existing workflows without hassle.

QR codes also store a bulk of data that can be tailored to specific needs, such as sterilization history.

Even more importantly, data retrieval stays reliable no matter the QR code’s size. The code can be smaller than a coin, for example.

Source: GoCodes Asset Tracking

Nevertheless, there are some disadvantages when it comes to scanning.

QR codes are not active trackers, meaning they use passive GPS technology and only provide the location of the item based on its last scan.

Moreover, each QR code tag has to be scanned individually, which can be time-consuming and inconvenient for higher-volume inventory.

When scanning a QR code you need to keep a direct line of sight to get an accurate reading.

In this respect, RFID tags are the opposite.

You can scan the RFID tag even through some material. Plus, RFID systems also provide real-time monitoring capabilities.

For healthcare professionals who are always hard-pressed for time, and yet need to do frequent stock counts, this feature is indispensable.

Here’s a quick recap of the main characteristics.

Source: GoCodes Asset Tracking

Different tracking technologies cater to different needs, so you want to choose a reliable vendor that can meet your needs in the long run.

GoCodes Asset Tracking offers all kinds of trackers, including both QR code and RFID solutions, which can seamlessly fit specific operational needs and constraints.

In the end, implementing advanced tracking technology for your surgical instruments is not an either-or choice—you can leverage both in a way that will fit your specific needs.

Conclusion

Today, effective surgical instrument tracking builds a strong foundation for improving patient safety while driving efficiency and innovation.

As technology advances, more and more opportunities for healthcare providers emerge to streamline their processes and safeguard patients.

Choosing the technology that will benefit you the most and implementing it can be challenging, but the time and effort required are definitely worth it.

By investing in the right tracking solution, you’ll empower your medical teams to focus on what matters most: delivering exceptional care.

The future of tracking is here, and if you haven’t already, now’s the time to embrace it!