Supply chain disruptions, spiraling inflation, and the need to pay laborers top wages in a competitive worker market mean that construction companies are more hard-pressed than ever to meet project budgets.

While market conditions are beyond the control of construction companies, project managers can take their own steps to save resources and recycle materials.

It’s not possible to repurpose everything found on a construction site, but many surprising materials, such as asphalt, can find new lives in completely different ways.

Read on to find out more about which construction materials you can recycle.

In this article...

Wood

Recycling wood is an excellent way to reuse construction materials. Leftover wood might be utilized in new floors, paneling, doors, windows, fences, and more.

Groundwood can also become particle board.

Valuable hardwood floors are often a welcome surprise to clients when they are discovered beneath linoleum or carpet, and with some sanding and refurbishing, these hidden treasures can save a bundle on flooring costs.

Refurbishing wood details that are adopted into a project is just one way of reusing wood.

For lumber that isn’t usable for another construction project, engineers, chemists, and designers have found surprising ways to put wood to use:

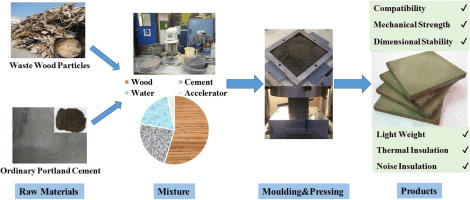

This visual aid shows how wood, when paired with cement and water, can undergo reprocessing to become eco-friendly particleboard that avoids using formaldehyde during manufacturing.

This product is suitable for many applications, as it is strong and lightweight.

Repurposed particleboard is utilitarian and dimensionally stable, and therefore excellent for thermal and noise insulation.

Here are some other uses for leftover or salvaged wood:

- Shipping pallets

- Mulch

- Molding

- Risers

- Baseboards

- Shelves

- Compressed wood

- Chips

- Subflooring

- Biofuels

- Finger-jointed structural lumber

According to one study, up to 17% of all landfill waste comes from construction sites, and the construction of one small single-family home creates between 1500-3700 pounds of lumber waste.

Choosing one of these many ways to recycle leftover construction wood, then, can preserve significant amounts of landfill space.

Metal

Metal is perhaps the most recognized candidate for construction waste recycling. It has long undergone reprocessing as a building material.

Steel, copper, aluminum, and other metals are often reused as needed. It is possible to shred, melt, or purify discarded metal into nearly any shape necessary.

Scrap metal dealers or recycling centers are usually happy to receive construction leftovers for resale. In fact, up to 30% of new steel has at least some recycled components.

Steel is often used to construct the frames of new buildings or remodeling projects, and steel from tear-down jobs is usually easy to sort from other construction waste.

In fact, according to architecture professor Kiel Moe, steel is the most-recycled byproduct of construction projects, and around 98% of steel scrap is reused.

However, that number drops significantly to just above 70% when it comes to recycling steel used in reinforcing materials or rebar.

Since this steel is usually embedded in concrete, it is often difficult to separate the two during demolition.

However, planning ahead for selective dismantling can enable the rescue of even structural steel.

Advancing technology and the strong financial return on recycling steel construction materials means that the waste reclamation process is becoming increasingly more refined and efficient.

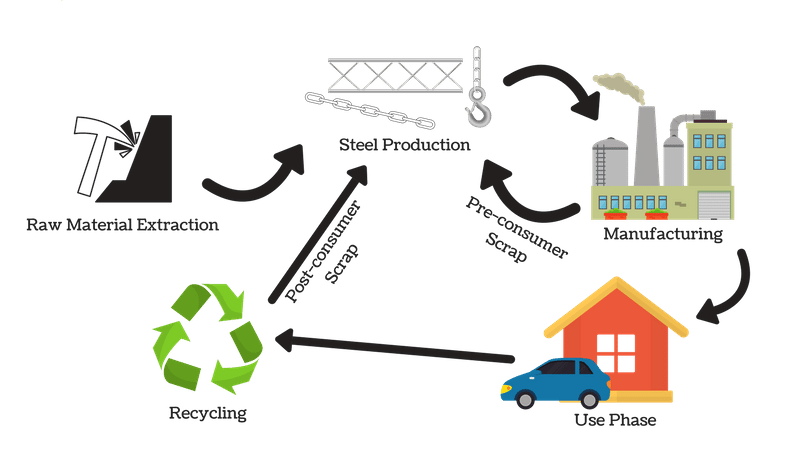

Steel recycling usually follows this procedure:

As this flow chart indicates, avoiding the mining of raw material means a tighter procedure that saves money on raw material extraction.

Use phases can take many forms, and the ability to utilize both pre-consumer scrap as well as post-consumer scrap makes for almost limitless manufacturing possibilities.

Glass

Glass shards and ill-fitting windows are, like metals, formable into other products. The use of recycled glass, however, stretches far beyond life as another window.

Glass can undergo recycling into fiberglass insulation, decorations, consumer goods, and aggregate gravel.

At the same time, the raw material used to make glass—sand or silica—is rarely in short supply, and glass windows often undergo coloration, lamination, or other chemical treatments to render it more efficient and better able to act as insulation.

Still, recent successful applications of recycled glass include turning it into sports turf, abrasives, or filtration mediums.

If you are eager to move along the glass reclaiming industry, train your team in the safe handling of glass waste, as separating it from other construction leftovers is important in the decontamination process.

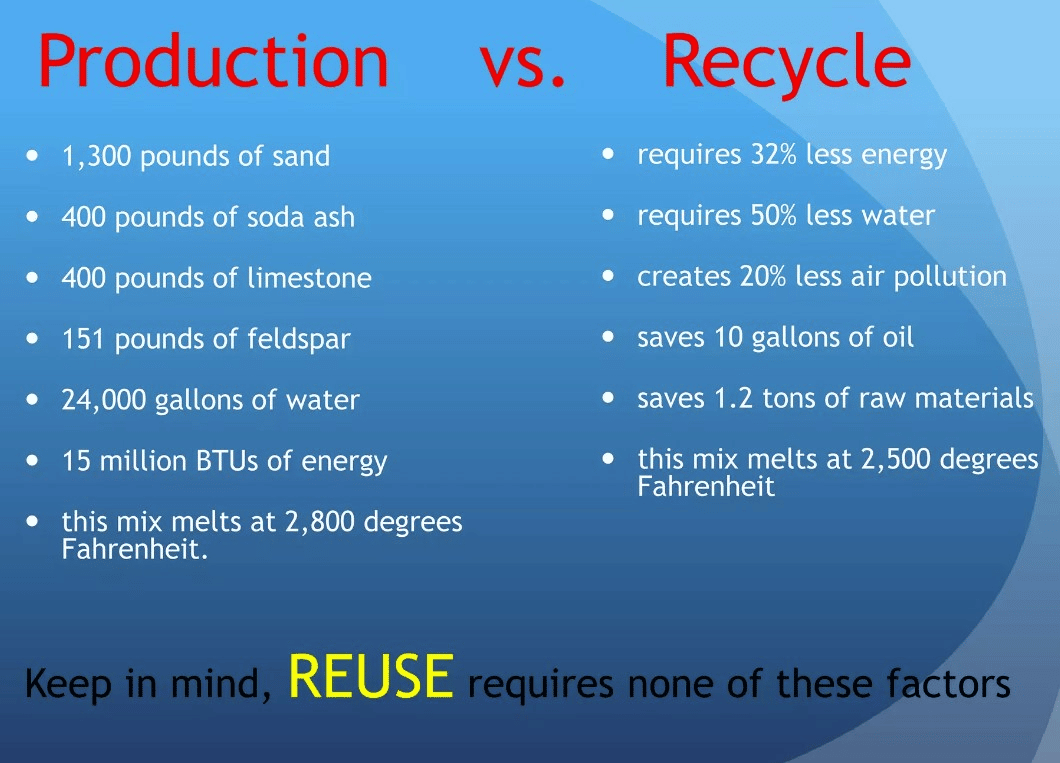

This comparison list shows the tremendous savings that are achievable if creative architects and engineers are dedicated to finding ways to use recycled glass—or, better, to reuse it without extra processing:

Recycling glass from construction sites mostly sees its return in energy savings.

According to the World Wildlife Federation, committing to recycling glass rather than producing new material can reduce related water pollution by 50% and related air pollution by 20%.

Plastic

While the construction industry is notorious for contributing a great deal of lumber and concrete waste, it typically only makes for 4% of Earth’s plastic waste.

Plastic waste on construction sites usually comes in the form of wrapping, protective materials, and temporary supports for builds in progress.

The potential applications of salvaged plastic are many:

- Roofing

- Pipes

- Window frames

- Fencing

- Doors

- Glazing for windows

- Skylights

- Toys

- Ducts

- Scaffolding boards

- Thermal panels

- Flooring

- Consumer products

- Interior fittings

- Playground equipment

- PVC windows

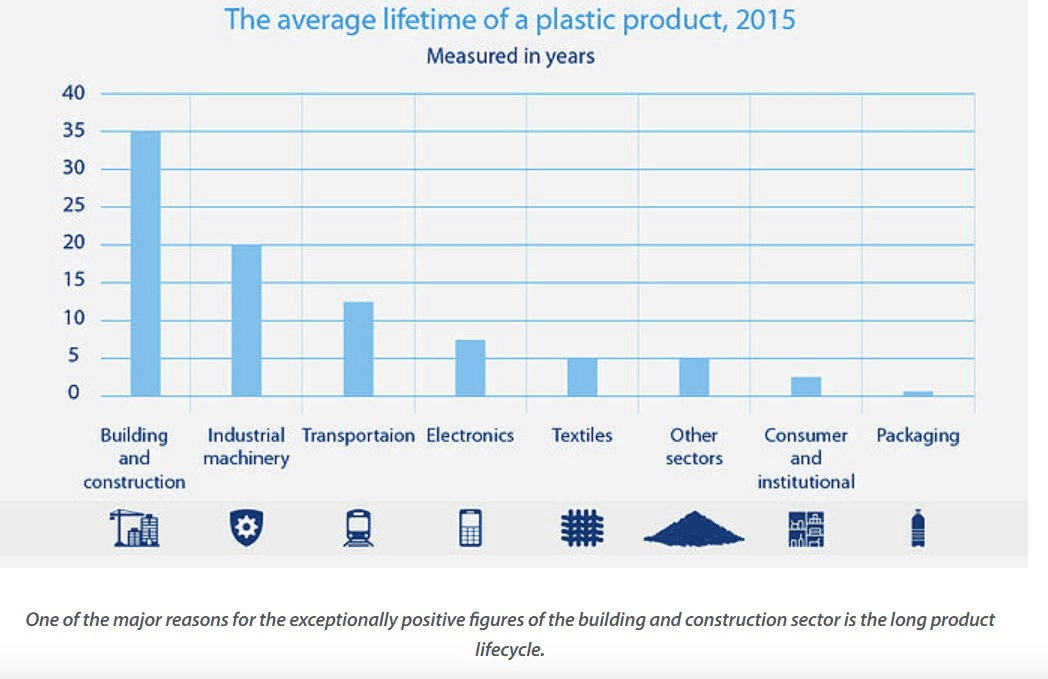

One of the reasons for construction’s strong record in the environmentally responsible use of plastics is its long product life cycle.

Once the plastic is in place within a construction project, it tends to last many years, as this bar graph shows:

When construction plastic recycling takes place, it usually takes the form of packaging, landscaping, and insulation.

Most plastic construction waste comes from wrappings and food packaging for crew members.

About 25% of construction plastic waste, in fact, issues from build packaging, says Invest Northern Ireland.

Drywall

Also known as plasterboard, gypsum board, or its most popular brand name, Sheetrock, drywall is a constant on almost every construction site.

It is a building material made mostly from gypsum and surrounded by paper.

Drywall is most typically used in construction to provide increased mildew resistance for the interior walls of a building.

It’s also useful in repelling water and providing some measure of fire protection.

Where construction materials are concerned, drywall was introduced at the turn of the 20th century, but did not come into common use until during the building boom after World War II.

Because of its relatively recent addition to the construction industry, drywall usually contains at least some processed materials, such as manufactured boric acid, plastic, and even formaldehyde.

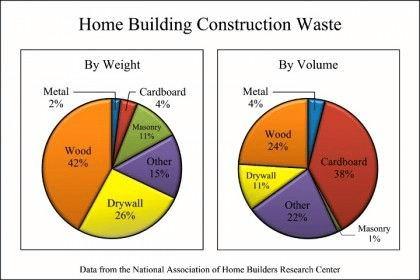

Of all the waste from construction sites, drywall can constitute up to 25%.

As a result, Gypsum Recycling International estimates that about 40,000 tons of drywall a day ends up in landfills.

Drywall is recyclable to become more drywall, but only if it is true scrap and has not become wet or contaminated with paint or dirt.

Still, from an environmental point of view, the paper surrounding the gypsum is subject to recycling like any other type of paper or wood material.

The most recyclable item in drywall is its gypsum.

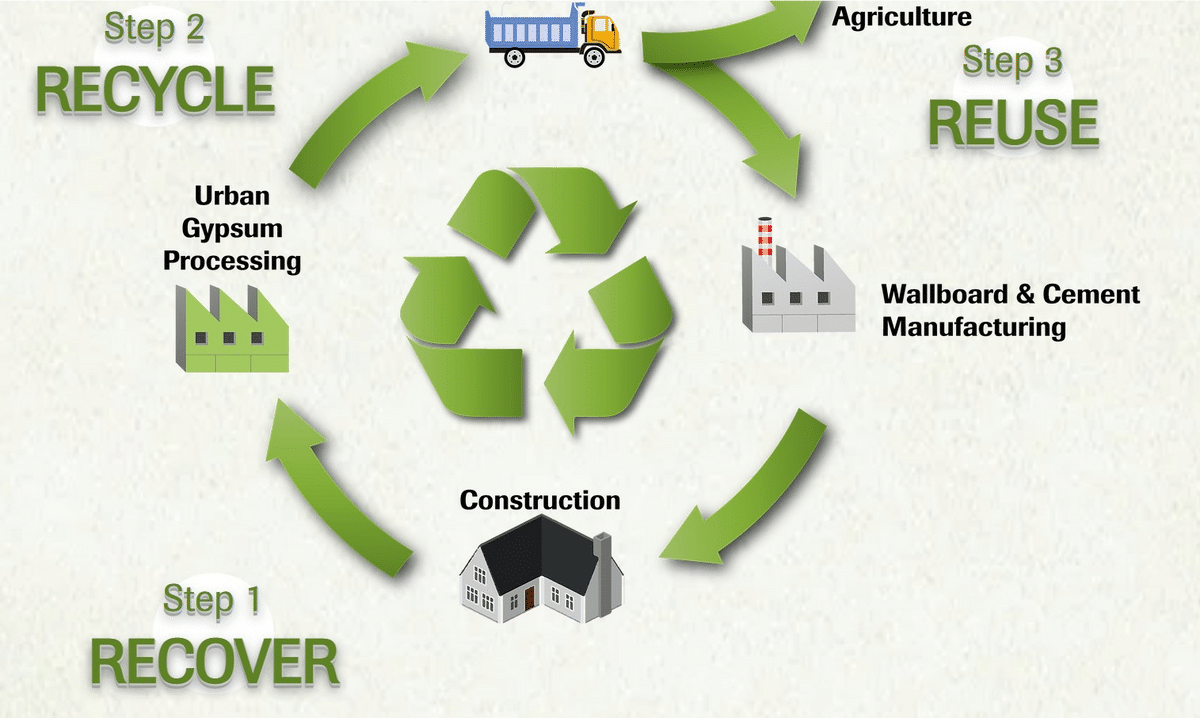

This graphic shows the process of recovering gypsum from drywall:

As the above visual shows, recycled gypsum also has industrial applications in addition to agricultural uses.

Drywall is reused to plug holes in walls or turned into agricultural products because gypsum contains boron, which is a plant nutrient.

The gypsum used in drywall might also undergo another life as compost or a concrete additive.

Masonry

Leftover masonry can undergo cleaning and possible brick reforming for other construction projects. In some cases, masonry can undergo crushing for the production of new masonry.

It can also appear in road construction bases, landscaping, and more.

Bricks that were used to support a foundation, though, are often unusable for the same task, as they are more liable to take on moisture and are usually unreliable for sustaining heavy loads.

It is also often difficult to remove the mortar from bricks used in walls or foundations.

This pie chart shows that masonry isn’t responsible for much construction waste by volume, but by weight, its contribution is quite significant:

One of the ways to reduce the waste associated with construction masonry is to grind it up on site.

Not all repurposed bricks can bear as much weight as they did when originally laid.

Still, bricks are typically made from shale and other mined materials, so reusing them when possible—on top of a decorative wall, for example—can result in a positive environmental impact.

Recycled masonry is usually most useful in a chipped or crushed state.

Uncontaminated masonry materials can find another use in small hobby construction projects, walls, parking lots, and as brick powder for running tracks or baseball diamonds.

They also make useful doorstops or attractive planters.

Concrete

Concrete and asphalt rubble left over from a construction project is recyclable for other projects. These materials are common, but not recycled as often as steel or other metals.

Some experts estimate that if every construction company’s concrete waste in the US were recycled, the energy savings would equal about a billion gallons of gasoline.

Subcontractors can crush and remix it for new concrete. Of course, concrete is a common sight in urbanized areas; it appears in sidewalks, utility passages, roads, and landscaping projects.

Concrete is also widely used in the consumer industry for non-construction purposes. Recycling this common item, then, saves resources in many different ways.

In the United States alone, according to the Concrete Materials Recycling Association, about 140 tons of concrete undergo recycling.

Concrete is heavy and non-biodegradable, so transferring it to a crushing center rather than a landfill helps to free space for forms of non-reusable waste.

Some construction companies institute concrete separation and crushing in the field, then reuse it in other forms.

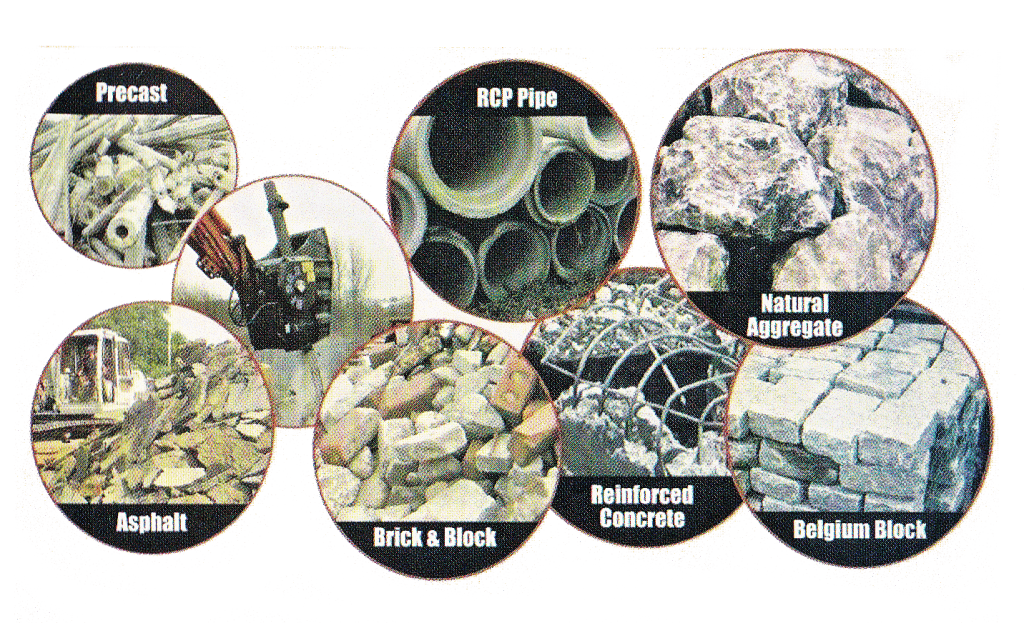

Source: CivilArc

This graphic shows the many ways in which recycled aggregate concrete can take on new roles after reprocessing.

However, concrete recycling is not as technologically advanced as metal recycling, and it is usually not appropriate for structural applications.

The use of natural aggregates is still typically preferred for their superior ability to bear weight, remain durable, and repel water.

With further study and experimentation, the use of recycled concrete will likely rise in the future, especially as raw materials continue to remain in short supply.

Asphalt

Recycled asphalt is useful when crushed and reused for paving roads, and the National Asphalt Pavement Association states that it is one of America’s more recycled forms of waste.

Thanks to technological advances in asphalt reclaiming, this product is highly recyclable because its quality usually matches or even exceeds the original material.

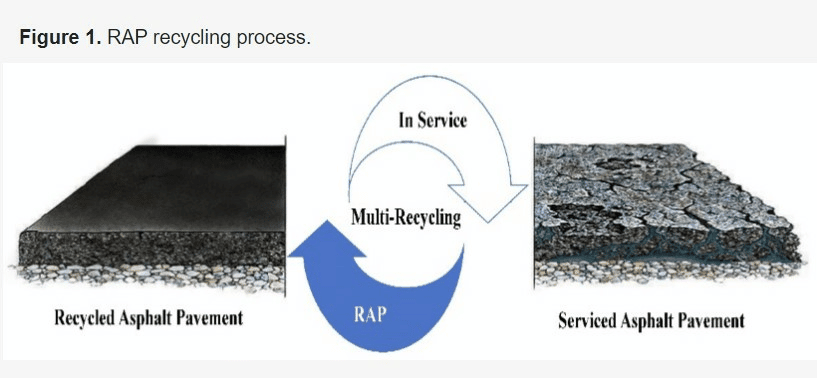

Asphalt can undergo many reclamation cycles, and it’s always needed for roads and parking lots.

American Asphalt says that recycling this material can result in savings of anywhere between thirty to eighty dollars a ton.

Reclaimed asphalt pavement undergoes an efficient work cycle, as shown here:

Recycled asphalt prevents the source material from sitting in a landfill, where it will not decay.

Most reprocessed asphalt is used for repairs rather than new roads because it might require more cleaning than virgin asphalt, and, depending on its location and source, might cost more initially.

Conclusion

While not all construction materials are appropriate for reuse in their original form, they can often serve as compost, road beds, or in landscaping projects.

Ensuring that your team handles and separates these items properly can conserve gas and save money when it’s time to restock.

Wood, metal, glass, plastic, drywall, masonry, concrete, and asphalt can all be reused in the construction industry, sometimes in surprising ways.