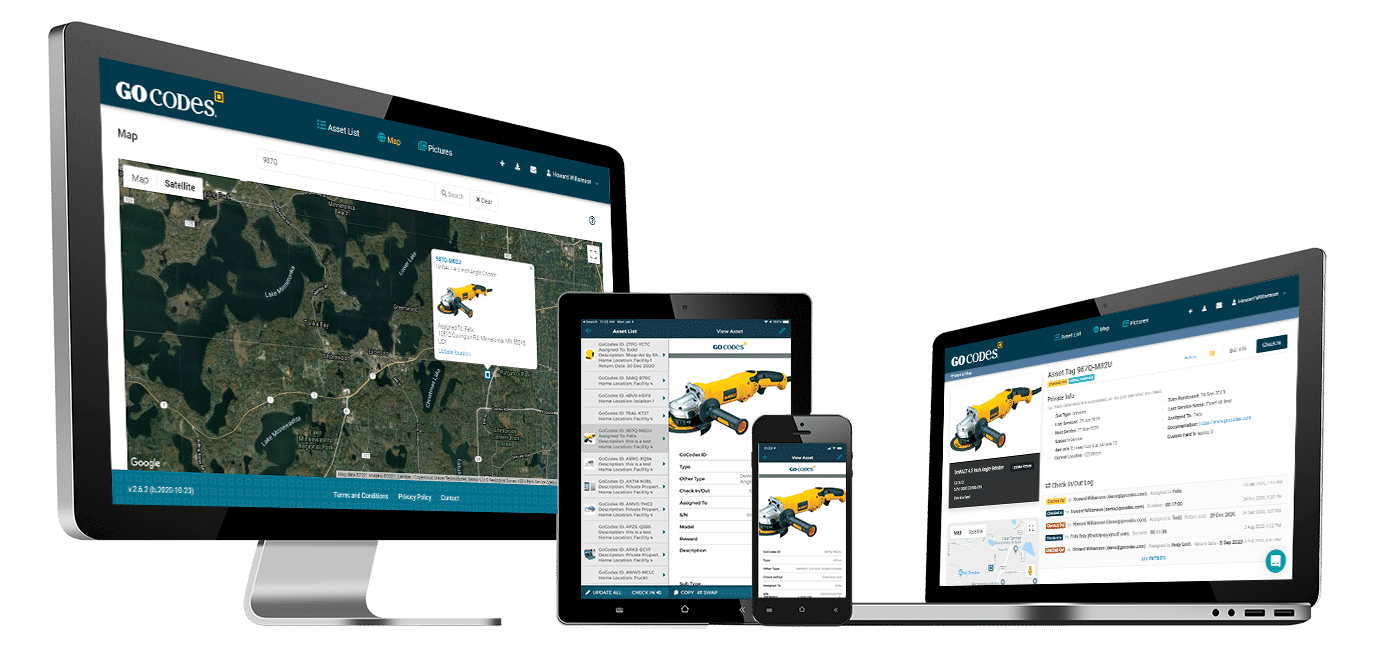

Trusted by 1,000+ businesses for the past 14 years

Real-Time Warehouse Tracking Without The Enterprise Nightmare!

2 week vs 6+ month implementation

Deploy instantly with smartphones. No consultants, no IT infrastructure needed

Total solution software + hardware

QR labels + mobile apps + training. Others charge $2K for scanners alone

Mobile-first for warehouse reality

Scan with any smartphone. Works offline in dead zones. No trips to computer terminals

Hidden Costs of Poor Warehouse Tracking

Manufacturing and distribution operations lose billions annually to inefficient inventory management. But for mid-sized warehouses managing 5,000-50,000 SKUs, the real pain hits closer to home:

Warehouse workers waste significant shift time hunting for items

1/3 of businesses ship orders late due to inaccurate stock counts

Emergency purchases cost 50% more than planned procurement

Equipment hoarding creates artificial shortages while duplicates gather dust

How Warehouse Inventory Tracking Actually Works

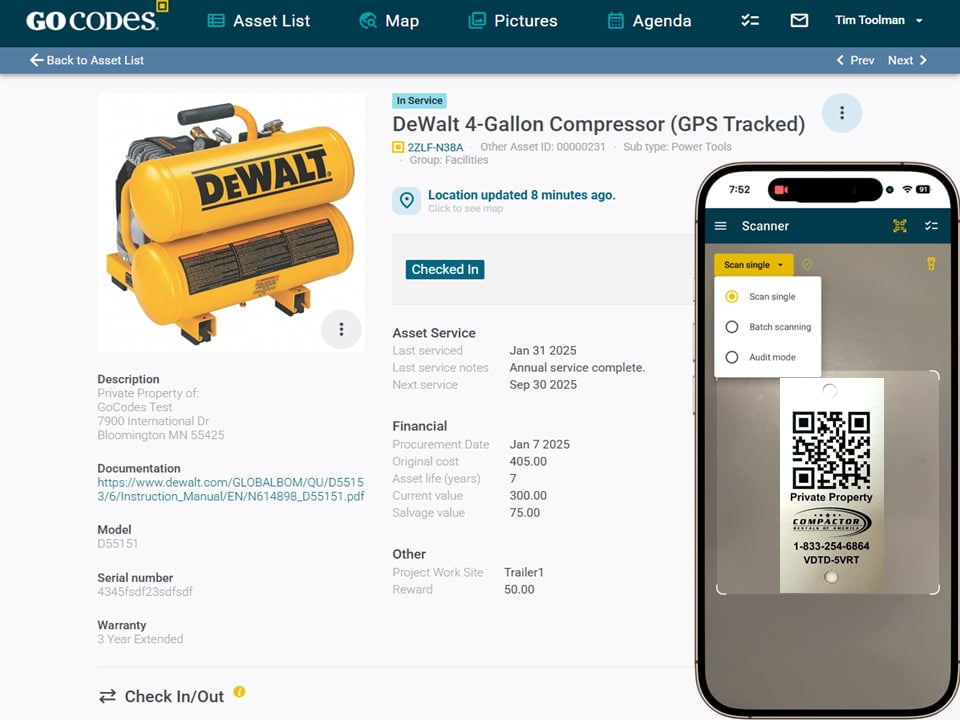

1. Rapid QR Code Deployment

Apply weatherproof QR labels to tools, equipment, parts bins, and storage locations. Unlike RFID systems requiring $50,000 in readers, QR codes work with any smartphone camera.

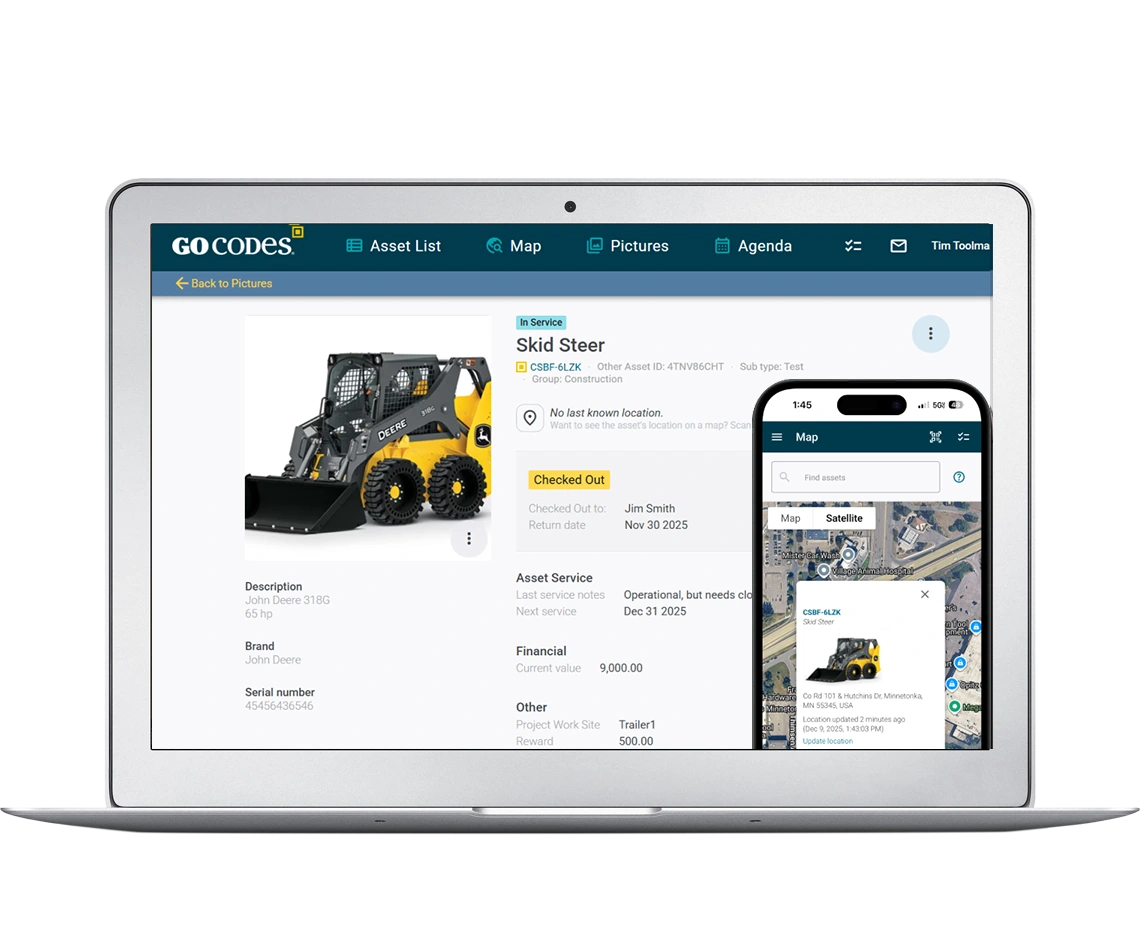

2. Mobile-First Tracking

Workers scan items during picking, putaway, transfers, and usage. The mobile app works offline in dead zones and syncs automatically. No handheld scanners, no docking stations, no IT headaches.

3. Instant Stock Intelligence

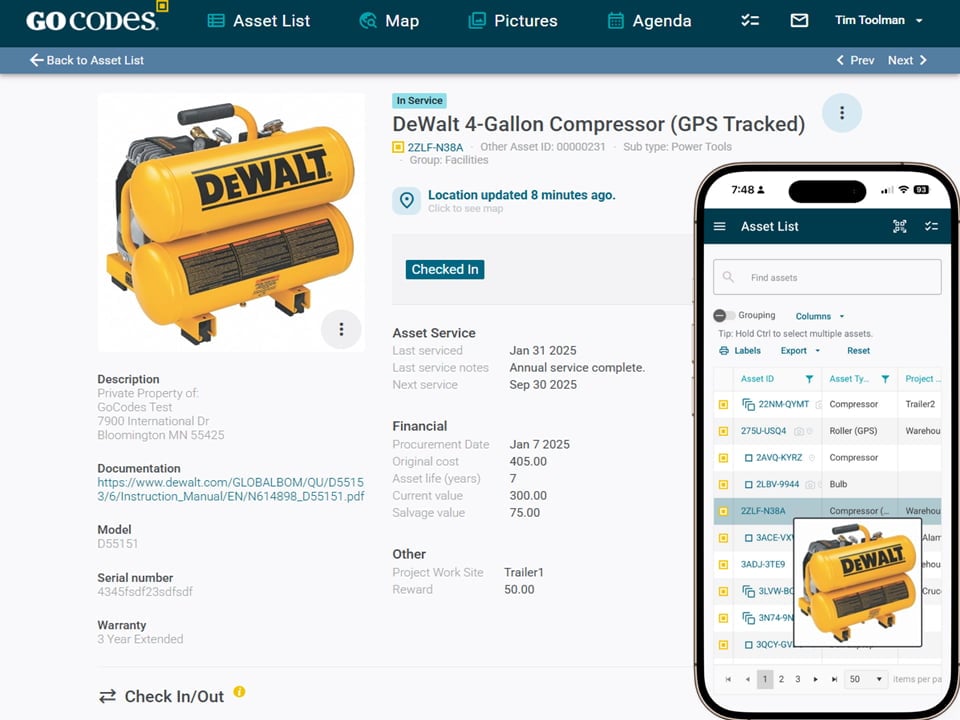

Real-time dashboards show exactly what’s where, by zone, rack, bin, or project. Low-stock alerts prevent stockouts. Usage reports reveal consumption patterns. Audit trails track every movement.

4. Seamless Integration

Connect with existing ERP, accounting, or procurement systems via API. Export to Excel for management reports. No rip-and-replace required.

Built for Manufacturing & Warehouse Reality

Tool & Equipment Management

Your maintenance team’s $50,000 tool inventory walks out the door faster than you can reorder. GoCodes stops the bleeding:

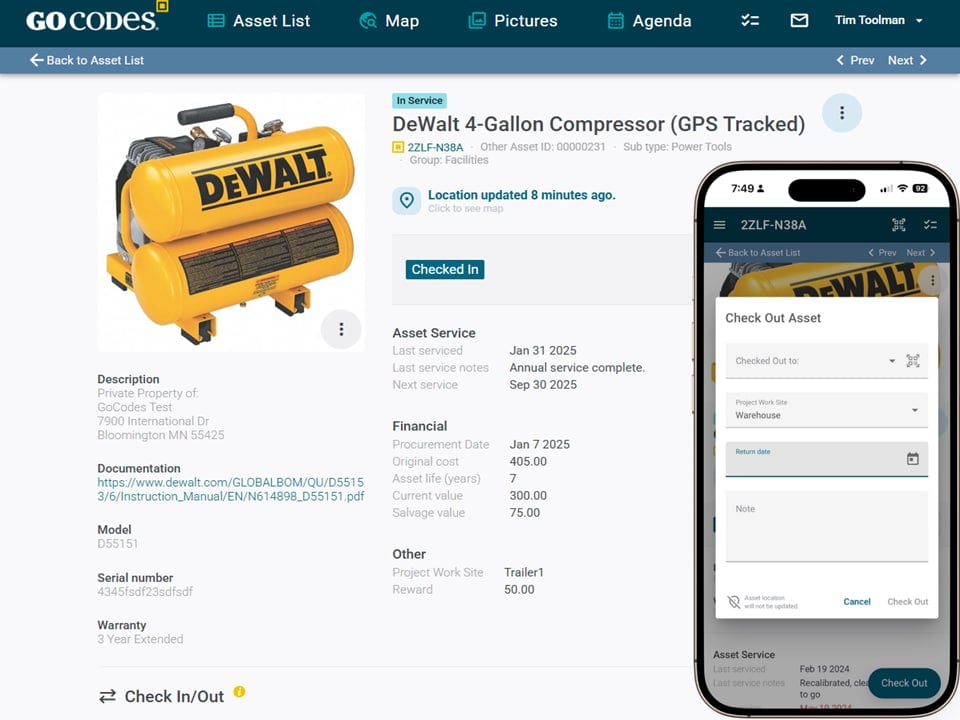

- Check-out/Check-in System: Workers scan tools when taking them to job sites

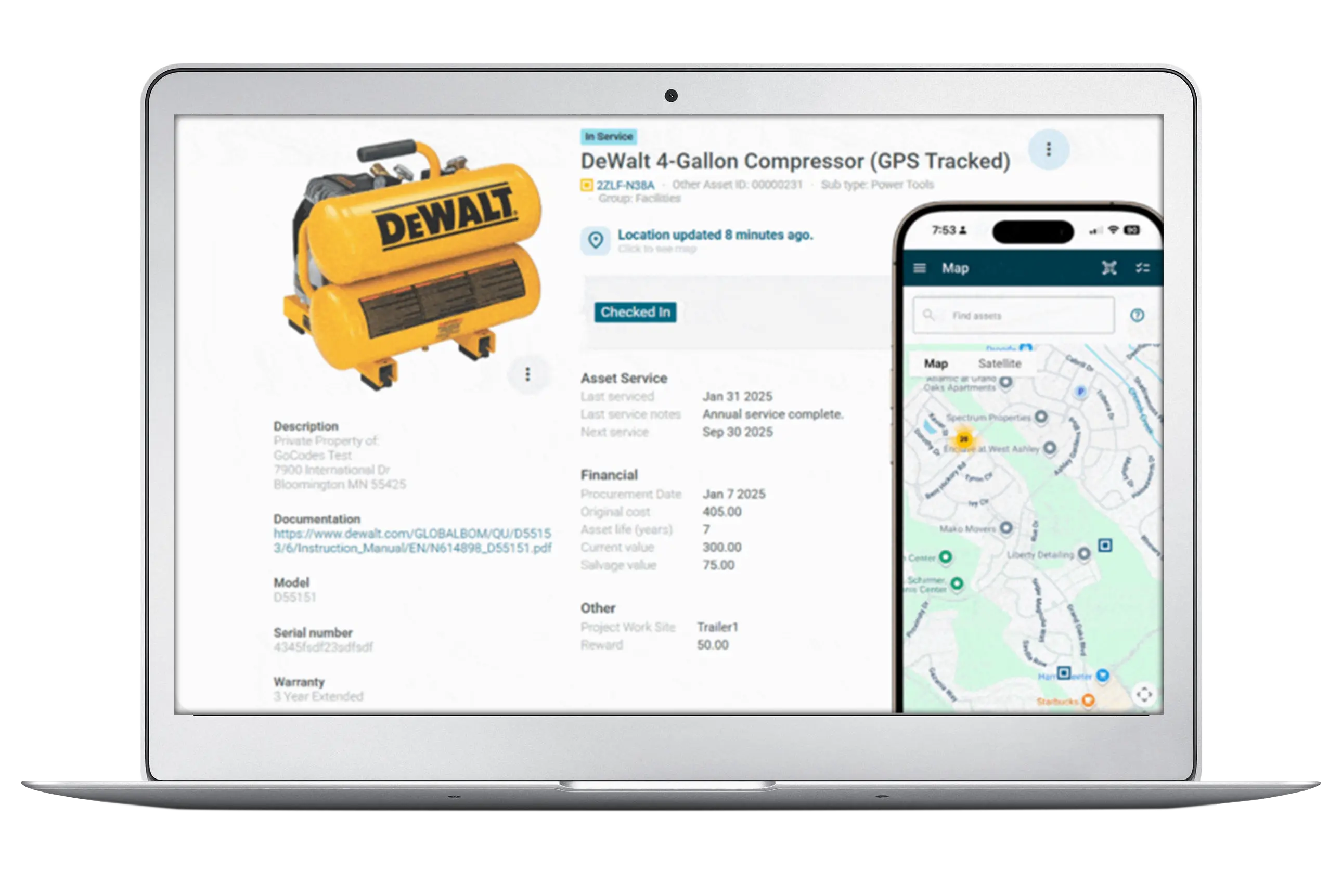

- GPS Location Tracking: See which tools are at which facility or truck

- Automated Return Reminders: Text alerts when equipment is overdue

- Usage Analytics: Identify underutilized assets for redistribution

Parts & Components Tracking

Managing thousands of parts across multiple bins, racks, and storage areas? GoCodes brings order to chaos:

- Bin Location Management: Track parts down to specific rack/bin locations

- Cycle Count Automation: Schedule and execute counts 70% faster

- Min/Max Level Monitoring: Automatic reorder alerts based on consumption

- Kitting & BOM Tracking: Ensure all components are available before production

Manufacturing Inventory Software

Bridge the gap between shop floor consumption and warehouse supply:

- Work Order Integration: Link inventory consumption to specific jobs

- Material Requirements Planning: Track components needed for production runs

- Quality Control Tracking: Monitor batch numbers and expiration dates

- Cost Allocation: Assign material costs to projects automatically

Industry-Specific Solutions

Small Business Warehouse Management

Mid-market operations need professional capabilities without enterprise complexity:

- Start tracking 100 items or scale to 50,000+

- No dedicated IT staff required

- Predictable flat-rate pricing

- Export data anytime, you own it

Manufacturing Execution Integration

While not a full MES system, GoCodes bridges critical gaps:

- Track WIP inventory between production stages

- Monitor tool availability for scheduled jobs

- Link material consumption to work orders

- Generate production efficiency reports

Construction & Contractor Warehouses

Manage inventory across multiple job sites and storage yards:

- Transfer equipment between projects instantly

- Track consumables’ usage by job

- Prevent tool hoarding with accountability

- Integrate with project management systems

“What if we need custom workflows?”

GoCodes adapts to your processes, not vice versa. Configure custom fields, approval workflows, and automation rules. Our Success’ team, helps optimize for your specific needs.

Asset Tracking ROI Calculator

How much money are you losing every year due to lost and stolen tools?

Warehouse Inventory Tracking Software Comparisons

GoCodes delivers 80% of the value at 10% of the cost and complexity.

Enterprise WMS (SAP, Oracle)

Enterprise systems are built for Fortune 500 complexity. For mid-market warehouses, that means:

- 6-12 month implementations

- $250,000+ total cost

- Extensive IT requirements

- Steep learning curves

GoCodes provides the structure of enter-prise software with spreadsheet simplicity.

Spreadsheet Tracking

Excel works until it doesn’t. Manual tracking creates:

- No real-time visibility

- Version control nightmares

- Zero mobile accessibility

- Human error multiplication

GoCodes is purpose-built for industrial operations, not retail stores.

Basic Inventory Apps

Consumer-grade apps lack critical warehouse features:

- No location management

- Limited user permissions

- No hardware included

- Minimal reporting

Key Features

QR Code & Barcode Scanning

Instant item identification with any smartphone

- Scan QR codes, barcodes, or serial numbers

- Works offline in warehouse dead zones

- No expensive handheld scanners required

- Bulk scanning for faster receiving

Real-Time Location Tracking

Know exactly where everything is, always

- Track items to specific bin/rack/shelf locations

- GPS tracking for tools and equipment

- Multi-warehouse visibility

- Visual warehouse maps and heat zones

Mobile-First Platform

Built for warehouse floor reality

- iOS/Android apps for all workers

- Offline mode with automatic sync

- Voice-to-text for hands-free notes

- Photo capture for condition documentation

Stock Level Management

Prevent stockouts and overstock

- Min/max threshold alerts

- Automatic reorder notifications

- Real-time quantity updates

- ABC analysis and optimization

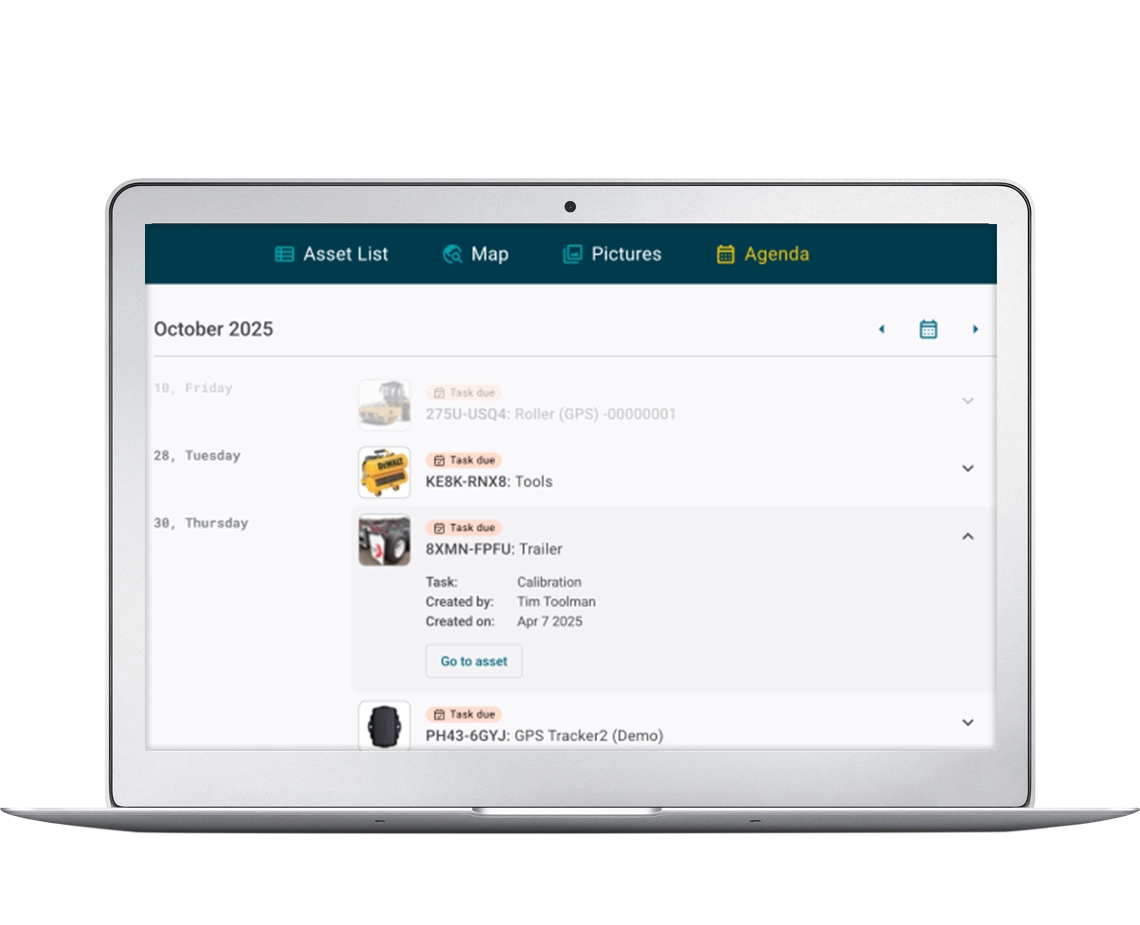

Cycle Counting

85% faster inventory audits

- Scheduled and ad-hoc counts

- Variance tracking and reporting

- Blind counts for accuracy

- Exception-based counting

Check-Out/ Check-In

Complete accountability for tools and equipment

- Employee assignment tracking

- Return date reminders

- Usage history and patterns

- Reservation system for high-demand items

Custom Reporting

Data that drives decisions

- 50+ pre-built report templates

- Custom dashboard creation

- Scheduled report delivery

- Excel export for analysis

Usage Analytics

Understand consumption patterns

- Track usage by project, department, or person

- Identify underutilized assets

- Predict future needs

- Cost allocation by job

Audit Trail

Complete transaction history

- Who, what, when, where for every movement

- Compliance documentation

- Loss investigation tools

- Chain of custody tracking

Automated Workflows

Reduce manual tasks

- Low-stock reorder triggers

- Maintenance schedule alerts

- Expired item notifications

- Transfer approval routing

Complete Hardware Package

Everything included, no hidden costs

- Unlimited QR code labels (weatherproof)

- Mobile scanner apps (unlimited users)

- Cloud hosting (99.9% uptime)

- Regular feature updates

Flexible Deployment

Adapts to your operation

- Start small, scale unlimited

- Add locations anytime

- Configure custom fields

- Role-based permissions

Why Customers Choose GoCodes.

See Why Our Customers Rate Us!

GoCodes Asset Tracking

Case Studies

At GoCodes, we pride ourselves on facilitating meaningful asset management. But don’t just take our word for it. Learn how we have created impact for our satisfied users.

FAMILY LEGACY MISSIONS

Transforming Lives In Zambia

J&M Keystone

Flood and Damage Restoration

Articles & Insights

Information to give you more tracking power

How to Start Barcoding Tools and Equipment In 5 Steps

Ready to automate your tool and equipment tracking with barcodes? Barcoding has been around far longer than technologies like BLE and RFID, and it remains one of the simplest, most effective asset tracking solutions your construction business can adopt. But before you...

QR Code Inventory Management Software Explained

Want better inventory control? QR code inventory management software simplifies tracking and organization!

6 Inventory Tracking Tips to Boost Efficiency and Accuracy

Looking to improve inventory management? These 6 inventory tracking tips will help you to streamline your operations!

5 Best Ways to Track Inventory Effectively

Learn key strategies and tools for maintaining accurate inventory records and optimizing supply chain management.

End-of-Year Inventory: The Ultimate Guide

Learn everything important about doing end-of-year inventory. Why do it, how, and which tools to use? We bring the answers!

We include patented QR code tags that can be customized to your project. They come ready to use with our web software and smartphone scanner apps.

Works on devices you already own

Our FREE scanner apps and tags mean there's no hand-held barcode scanners or printers to purchase – so you’re up-and-running fast.

Frequently Asked Questions

Learn more about features, security, integration capabilities, and more!

What is Warehouse Inventory Tracking Software?

Warehouse inventory tracking software is a cloud-based system that monitors stock levels, item locations, and inventory movements in real-time using barcode or QR code scanning. It replaces manual spreadsheets and clipboard tracking with digital workflows that show exactly what you have, where it’s stored, and who’s using it. The software combines mobile scanning apps, cloud databases, and automated alerts to prevent stockouts, reduce loss, and eliminate hours of daily searching. Unlike complex Warehouse Management Systems (WMS) which require 6-month implementations, modern tracking software deploys in days using smartphones and provides instant visibility across multiple warehouses, job sites, and storage locations.

How Does Warehouse Inventory Tracking Software Work?

Warehouse inventory tracking software works through four integrated components:

- QR code or barcode labels attached to items, bins, and locations

- Mobile scanning apps that capture movements in real-time

- Cloud software that processes transactions and updates inventory levels instantly

- Dashboards that display current stock, locations, and analytics

When workers receive, pick, transfer, or use items, they scan the code with their smartphone, select the action, and the system automatically updates quantities, tracks locations, and logs the transaction. The software works offline in warehouse dead zones, syncs when reconnected, sends low-stock alerts, generates reports, and integrates with existing ERP or accounting systems. Most systems include check-out/check-in workflows for tools, cycle counting features for audits, and usage analytics for optimization.

What's the difference between WMS and inventory tracking software?

Warehouse Management Systems (WMS) orchestrate entire fulfillment operations, wave picking, cross-docking, slotting optimization. Inventory tracking focuses on knowing what you have and where it is. GoCodes provides powerful tracking without WMS complexity, perfect for operations needing visibility without restructuring entire workflows. Most mid-sized warehouses need better tracking, not complex fulfillment orchestration.

How does this compare to RFID warehouse systems?

RFID requires $50,000+ in readers, gates, and infrastructure. QR codes work with any smartphone, no special hardware needed. While RFID reads multiple tags simultaneously, QR provides item-level detail and costs 90% less to implement. For most mid-sized operations, QR delivers better ROI without the complexity.

Can we track parts down to bin locations?

Yes, create hierarchical locations: Warehouse > Zone > Rack > Shelf > Bin. Scan items during put-away to record exact locations. Update locations during moves. Search by partial location names. Cycle count specific bins. Generate pick lists with location routing.

How does tool inventory software functionality work?

Specialized tool tracking features include check-out/check-in workflows, overdue return alerts, usage history by employee, maintenance scheduling, calibration tracking, and GPS location for mobile tools. Prevent hoarding, reduce loss, and ensure critical tools are available when needed.

How quickly can we implement warehouse barcode systems?

Most operations go live in 14 days. Week 1: Apply labels, configure system, import data. Week 2: Train team, pilot deployment, refine processes. This isn’t enterprise software requiring months of consulting. It’s practical tracking that works immediately. Complex operations might need 30 days for full deployment.

What's the real cost of warehouse tracking software?

Cloud-based warehouse management software typically costs from $100 – $500 per user per month. Onsite solution can cost from $2,500 to millions of dollars depending on the size of the operation and number of locations. Implementation fees can be considerable too. Lastly, any solutions require dedicated scanner hardware and special RFID tags that can run into thousands of dollars.

What about expiration date tracking?

Track expiration dates for perishables, chemicals, or certified materials. Set alerts for items approaching expiration. FIFO/FEFO picking recommendations. Compliance reporting for regulated industries. Prevent waste and ensure quality.