Power tools are an important part of your construction arsenal, which is why you want to keep them in top condition. Some of them tend to be quite expensive, and that is all the more reason to provide them with proper care and maintenance.

However, power tools get neglected too frequently, resulting in poor performance, breakdowns, and injuries.

That is why, in this article, we’re sharing 12 maintenance tips that will drastically increase the performance and lifespan of your power tools.

Let’s get started!

In this article...

Let the Tools Cool Down

If it seems that your tool is getting hot or starts shutting down, you should immediately stop using it and let it cool down. In this way, you will not wear out the motor or damage other parts of your tool.

But there are some other causes of tools overheating besides running them for too long.

For example, you could be applying too much or too little pressure while using them. Also, some brands are simply more prone to overheating than others.

If you’re noticing your power tools overheat regularly, our best advice is to nip this problem in the bud and take overheating into account when buying new tools.

For instance, if you are buying a new drill and want one that won’t overheat as much, you should avoid cordless ones, one-speed ones, and those that don’t have an anti-heating mechanism.

However, the key thing to do is to let your tools cool down. Just like your employees, your tools deserve to take a break every now and then, or they will overheat and get overused and damaged.

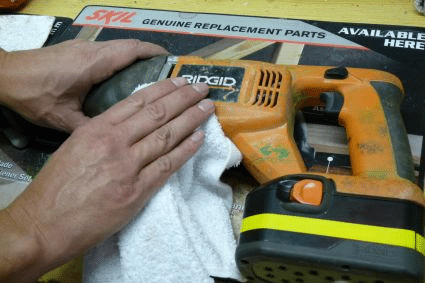

Clean the Tools After Every Use

If you want your tools to live long and prosper, you should clean them after every use. Most people have probably read that somewhere in their maintenance manual but choose to ignore it.

We understand that cleaning is the last thing on your mind after a hard day of work, but it’s not that hard and won’t take much time out of your busy schedule.

Start by simply wiping your tools with a clean, soft cloth to remove any dirt and debris. Don’t forget to inspect small crevices on your tools as well. You can use an air compressor or a pipe cleaner to reach them.

And that’s pretty much it! Easy, right? See, cleaning your tools takes only a few minutes a day, but it will keep your tools in top shape without being a strain on your budget.

Lubricate Your Power Tools

Another thing that will prolong the life of your tools is proper lubrication. Lubricating your power tools prevents corrosion, chafing, and overheating.

What is important here is to choose the right kind of lubricant suited to your tool. Different lubricants have different viscosity. Some tools may require wax, while others require graphite.

You can find out which lubricant is best for your tool in the user’s manual, together with the information on the frequency of application. When lubrication is done at appropriate intervals, the movable parts of your tools last longer.

The main point here is that using the correct lubricant at regular intervals helps maximize the life of your power tools.

Sharpen the Bits and Blades

Even though dulling is a natural process, dull bits and blades can strain the motor, reducing the efficiency of your drills, circular saws, chainsaws, broaching machines, and other tools.

Therefore, to avoid downtime and costly repairs and replacements, you should sharpen the working bits and blades.

But how do you recognize a blunt blade?

Well, several signs might indicate it’s time to sharpen your blade. For instance, the sound of your saw can change, or the blade might start to tear the wood. Also, a dull blade will take longer to cut through material than a sharp one.

When it comes to other bits, similar rules apply. The frequency of sharpening depends on how much you are using your tool and the materials you are using it on.

For example, if you notice that it has become more difficult to drill a hole into softer materials, it’s time to sharpen it.

Therefore, to prolong the service life of your chains, drills, and other tools, make sure to sharpen their bits and blades when needed.

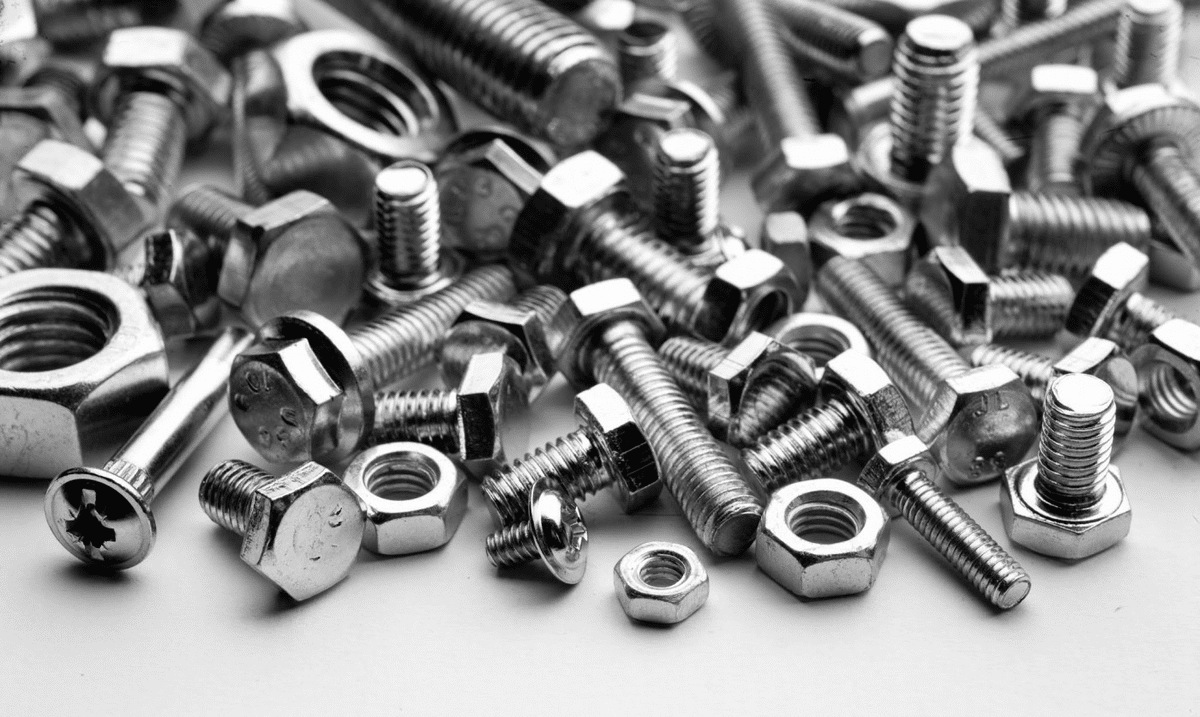

Tighten the Bolts and Screws

The constant use of your precious machines will inevitably lead to some loose bolts and screws.

You might be risking several issues by not addressing the loosenings and using your tools in such conditions.

For instance, the efficiency of your tools might decrease, or, even worse, your tools might end up severely damaged.

This is why it’s important to check your bolts and screws periodically and tighten all those that seem to be a little loose. For this purpose, you can use a number of tightening tools; screwdrivers, wrenches, drills, etc.

In short, you should check your power tools for loosened bolts and screws every now and then and tighten any you might find.

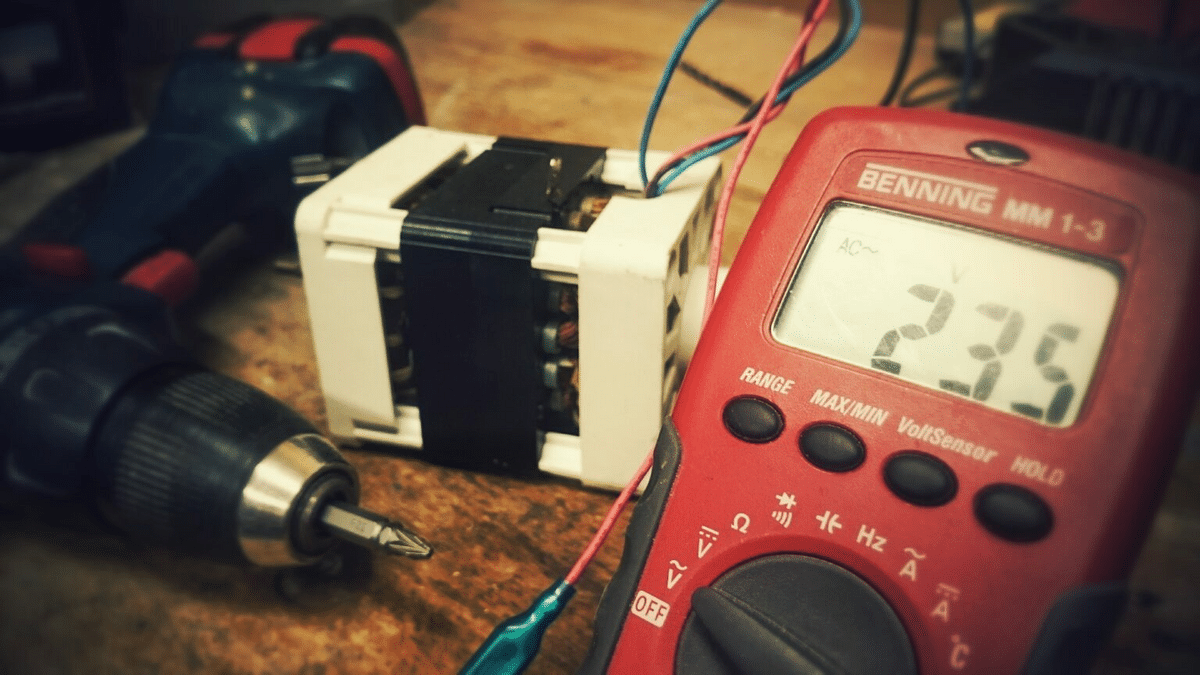

Pay Attention to the Motor Contact

The motor contact is an essential part of your power tools and should be cleaned after every use. Also, make sure to check if there is any damage to it and if you find a problem get it fixed or replaced as soon as possible.

Brushless motors are more durable, but if you have one with brushes, you will have to do your best to keep it in mint condition.

Your motor gets heated with use, so to cool it down, try blowing air through the vents for a few minutes every day. This will remove dirt and debris and increase the longevity of the brushes.

We’ve already mentioned the importance of cleaning your tools after every use. While doing so, don’t forget to clean motor contact as well and check it for damage to keep it in top shape.

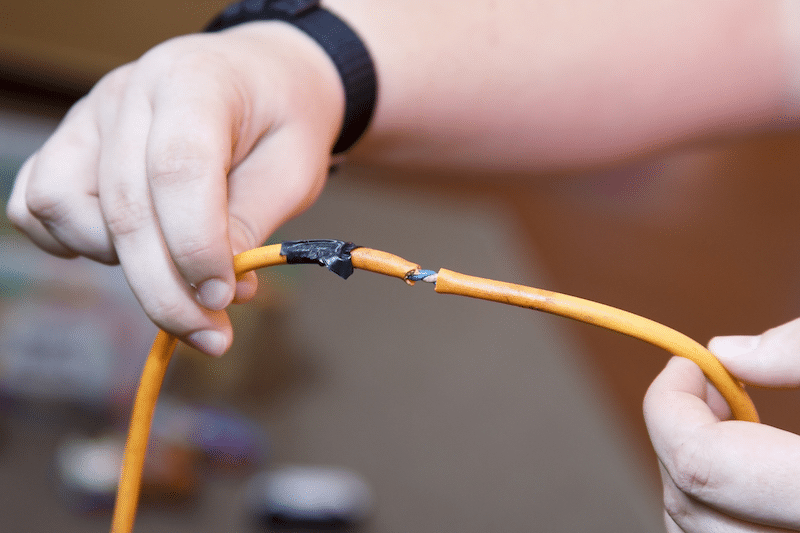

Keep the Cord in Good Shape

Power cords are definitely one of the most neglected parts of any tools and equipment, both in the household and the workplace.

It seems like nobody cares about electrical cords and cables, which is concerning since they can be a real safety hazard.

For instance, they can cause short circuits and even start fires. This is because cables get damaged, loose, or frayed over time.

Of course, all of this can also affect the performance of your power tools. That is why it’s important to regularly check your cords for any defects. Keep an eye out for any cracks or signs of wear and tear every time you use your power tools.

If you find something suspicious, don’t try to fix it yourself. Instead, have a professional take care of it. Trying to fix exposed wires on your own with scotch or duct tape is a bad idea.

All in all, cords are crucial for the life and performance of your tools, so make sure to check them for damage regularly and get them fixed if needed.

Calibrate Your Power Tools

Not all of your power tools require calibration, but some of them rely upon accuracy, so you’ll need to calibrate them on a regular basis to ensure that their power output is correct.

If the power output is too low, your tool will perform incorrectly. On the other hand, if the power output is too high, it might cause damage.

Calibration of some of your tools is actually specified by the ISO 9001:2015 standard, and you’ll need to get certified by professionals to prove they abide by it. Usually, this needs to be done once a year.

In this way, you will ensure that the precision of your tools remains at the required level.

Professionals usually say that if your power tool isn’t calibrated correctly, it’s better not to have one at all, and we have to agree with them. A correctly calibrated tool will have improved speed, performance, and life span.

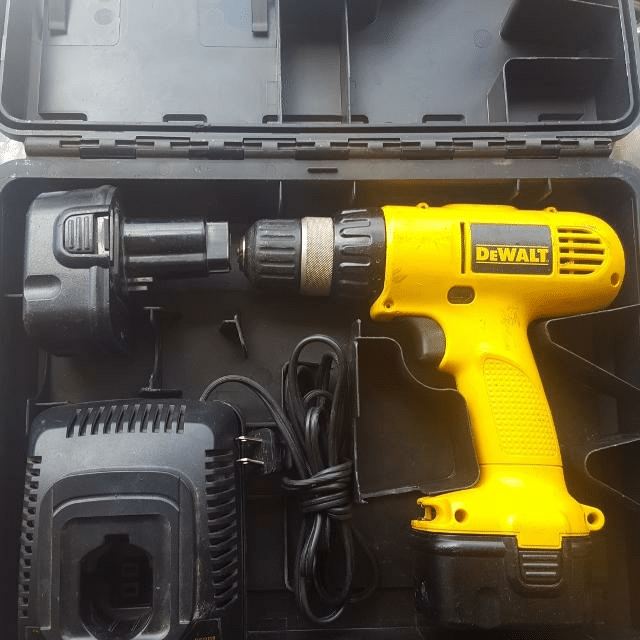

Store Your Tools Adequately

Proper storage is essential if you want your tools to last longer. It goes without saying that electronics get damaged if they come in contact with moisture, so make sure to store your power tools in a dry and clean place.

However, if you’re still worried, silica gel packs might provide you with some extra protection. You can put some in the drawers and on the shelves next to your power tools to keep the moisture away.

Our next advice in battling moisture is to keep your tools in their original cases. Most of the time, when you buy a power tool, it will come with a nice sturdy case, so don’t throw it away!

We know that it takes up some extra room, but it also protects your tools from various environmental factors and dust.

So, to protect your tools, you should store them in a dry place, use silica packs and keep them in their original cases.

Replace Worn Parts on Time

Some parts of your power tools are disposable and in need of regular replacement, while other parts might simply get worn out over time.

For example, after many years of hard work, the handle on your drill might get loose. Layers of duct tape won’t do the trick; you should replace the handle to prevent further damage to your drill.

You can perform some simple replacements by yourself, but be sure to leave more complex ones to the professionals.

Even if your tool has a small and seemingly insignificant defect, it can cause major issues down the line. Hence, it’s better to replace the problematic part straight away and save yourself money and trouble in the future.

So, the takeaway is; never delay the replacement of worn-out parts because even the most minor defects can turn into larger problems quickly.

Take Care of the Battery

Another thing that can cause you a lot of trouble is neglecting the batteries of your cordless power tools.

Did you know that a faulty battery can damage the entire tool? This is why it’s important to handle it with care and keep an eye on its condition.

For instance, if the battery is running out too quickly, that’s an indication it won’t last much longer and that it’s time to replace it.

However, there are several practices that can prolong the life of your batteries. The first one is simple; you should use them.

Yes, the more you use your batteries, the longer they will last you, so put your battery-operated power tools in use as much as you can.

The second thing that will help your batteries last longer is proper storage. Make sure to keep them in a dry place, away from moisture.

And the third thing is to recharge your battery as soon as it starts to decrease in power. It’s a good practice to recharge it when it reaches 70% of its capacity.

To sum up, while it’s important to replace your batteries on time before they damage your tools, taking good care of them will prolong their lifespan.

Keep Track of All Tools and Their Parts in a Centralized System

It’s a known fact that good organizing skills save time and money, so having a centralized system to track all of your power tools and their parts is a must if you want to extend their lifespan.

It’s always a good idea to keep some spare parts around, and a centralized software system will help you monitor and optimize your inventory.

After all, you want to have enough spare parts, but you don’t want to overstock; it’s all about balance.

For instance, our tracking system GoCodes Asset Tracking, enables easier tracking and maintenance, and allows you to label and track all tools and their condition thanks to its patented QR tags.

You can simply scan the QR code to find out everything you need to know about a tool from your collection.

Technology has, once again, proven to be your friend. With the right choice of software, you can track and manage your power tools and monitor your inventory levels easily.

Conclusion

Power tools are very useful on a construction site, but they can easily undergo wear and tear.

It’s no secret that your tools will last longer with regular care and maintenance, and you will also prevent those costly repairs. Unfortunately, many people are unaware of this or decide to ignore it.

In this article, we’ve given you 12 maintenance tips, so put them into practice, and your power tools will last longer for sure.