Asset tagging is a vital part of asset management. Using adequate labels helps you track all of your valuable assets and prevent mishandling or theft.

Asset tags are extremely accessible, easy to use, and come in various sizes and materials. Because of this, they can be found virtually everywhere, from construction sites to public institutions such as libraries.

In this article, we’re going to cover metal asset tags: their characteristics, main benefits and applications, as well as how to use them with your equipment. This way, you’ll have a better understanding of whether this type of tag is suitable for your needs.

Let’s dive in!

In this article...

Characteristics of Metal Tags

First, what are metal asset tags?

As their name suggests, they are identification tags made from sturdy metals that display the information necessary to identify the object they’re attached to. The materials they’re made from guarantee durability in most harsh environments.

Those are usually very robust metals, such as:

- brass

- anodized aluminum

- stainless steel

- cold-rolled steel

Each of these materials is resistant to a wide range of temperatures, but they also prevent scratches and corrosion.

The next thing you need to know is how asset information is put onto the metal tag. This will determine for how long the information will be legible on the metal tags. Some tags are more durable, while others fade within a couple of years.

Here are some of the main processes used to put asset information on a metal tag:

| Process | Pros | Cons | How it works |

|---|---|---|---|

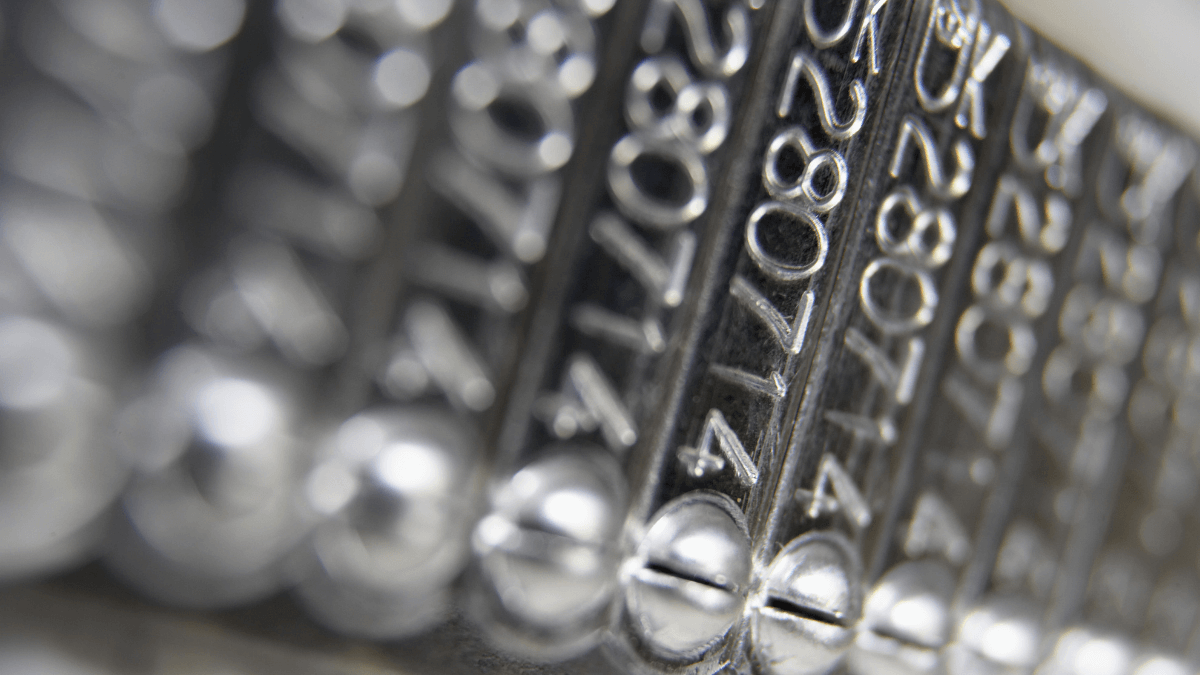

| Embossing | Extremely durable Information stays permanently Wide range of applications | Only essential information is stamped. | Use stamps to set information permanently. The tags have an indented design with raised characters. |

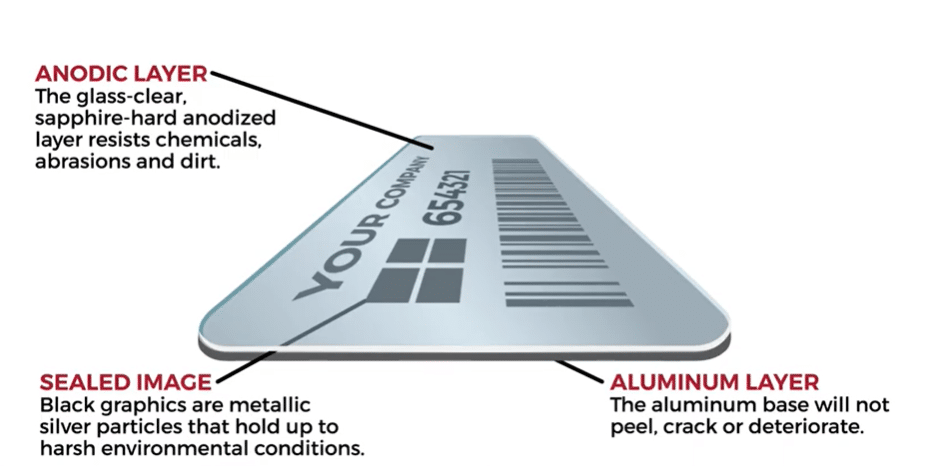

| Photo anodization | Allows you to create custom logos and barcodes Great outdoor durability Corrosion-resistant Resistant to fading and wear | Metal is impregnated with a silver compound and creates an image under the anodized layer. | |

| Etching | Last for 5-10 years, depending on the conditions | If the etching is colored, the color will fade quicker than the etching. | The laser removes a small amount of surface material. |

| Screen printing | Economical Produces colorful designs and images | A lower level of durability Wears easily | Ink is printed directly onto the metal surface. |

The final great thing about metal tags is that they come in many shapes and sizes. They can be square or round, with various metal thicknesses. But in the end, most companies can provide custom metal tags according to your specifications.

With a wide range of metal characteristics and processes used to set information onto metal, there’s surely the perfect metal tag for your business out there.

Benefits of Metal Tags

Now, let’s take a closer look at some benefits of using metal asset tags.

First, there is no better way of tagging equipment when you need durability. Metal tags often outlast the equipment they’re attached to! It’s no wonder that this is the primary reason most companies opt to use metal tags.

As mentioned before, the materials used in their production allow such tags to withstand extreme temperatures of over 900 degrees Fahrenheit.

Additionally, they can remain undamaged by almost any harsh chemicals or in extreme weather conditions and are abrasion-proof.

Basically, whatever you throw at your metal tags, they’ll be able to handle it.

What is more, they’re nearly impossible to remove once attached. Nobody will be able to tamper with your tags without some serious effort, so they’re excellent for theft prevention.

Another thing to keep in mind is that once you etch your data onto the metal, you can’t change it.

That is an added security measure for most companies, but it means you have to be exceptionally careful when you’re putting information on your metal tags. If you make any mistake, you’ll have to remake the entire tag.

Metal tags are not only functional, they can also be decorative. You can make them in any shape and color you want, as well as include text and company logos.

These reasons make metal tags the perfect solution for tagging equipment where durability in a harsh environment is necessary.

Where to Use Metal Tags

We’ve already emphasized how durable metal tags are. This is particularly true when compared to asset tags made of other materials, such as paper or plastic.

But if you compare different types of metal tags, some are better suited for certain equipment and environments than others.

For example, anodized aluminum tags can last for 20 years in outdoor environments, so they’re ideal for your heavy equipment. Nevertheless, you can also use them on lighter assets such as laptops and machine tools.

The same goes for stainless steel tags because they have similar resistance abilities. You’ll see stainless steel metal tags in medical, chemical, and food processing facilities.

Their incredible resistance to harsh chemicals and solvents allows them to be widely used in these industries.

On the other hand, screen-printed metal tags last between 1 and 3 years, so they’re best used for indoor spaces. If you expose them to sunlight and rain, they deteriorate more quickly.

A similar thing happens with etched metal tags. While they’re more durable, with an expected lifespan of 5-10 years, they’ll last longer in indoor warehouse conditions than in areas exposed to rain.

As you can see, there are many applications for metal tags, so it’s easy to find the types that fit your equipment and conditions better than others.

How to Apply Metal Tags to Equipment

After you choose the right type of metal asset tag, the main question is, how do you apply them to your equipment?

First, the placement of your tags is very important. Because most metal asset tags are rigid, they should be attached to a flat surface. Additionally, put them where you can easily find them and make sure they’re the right size.

After you’ve determined the location and size of your tags, you can look for suitable ways to put them on your equipment, such as:

| Holes | Some metal tags come with predrilled holes in one, two, or four corners. Use screws or bolts to mount them on a surface. |

| Welding | Attach the metal tag directly to the surface to avoid screws getting loose. |

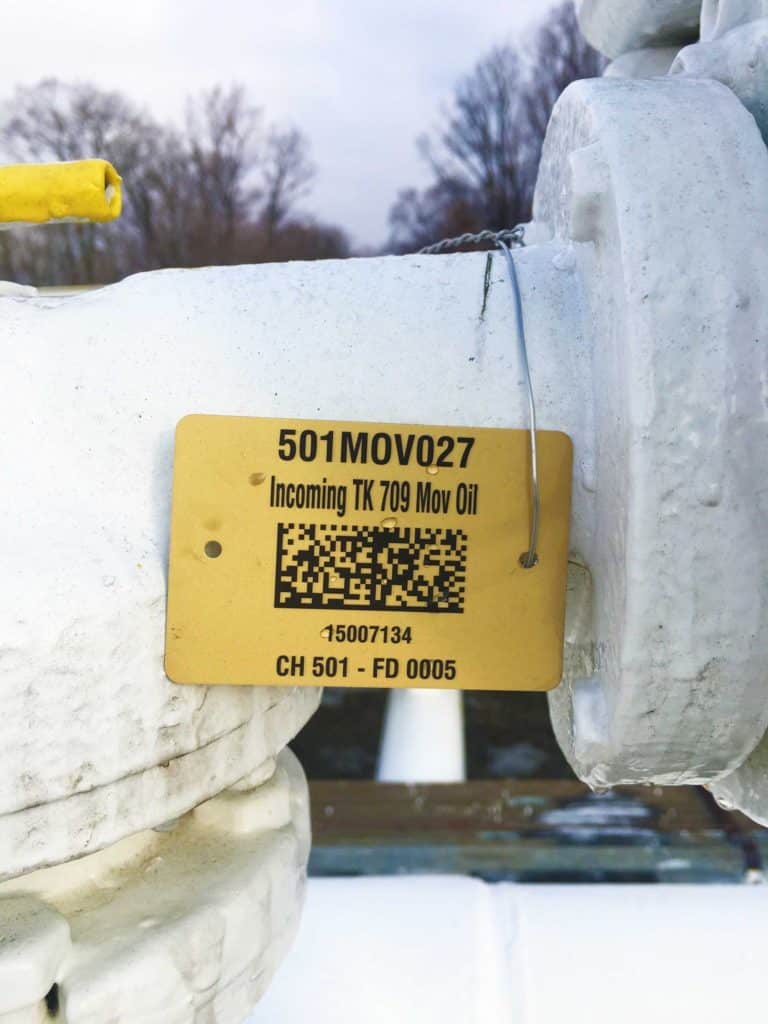

| Wires/chains | For non-flat surfaces, attach a metal tag to a wire and wrap it around your asset. |

| Adhesive backing | Add a thin paper to the back of your metal plate that you can easily peel off if necessary and apply a strong adhesive. Place on a clean surface and leave to set for 24-48 hours. That’s a quick and mess-free way of attaching metal tags. |

In the end, properly placing and applying your metal tags also ensures that you maximize their durability. Your equipment will be easy to scan and track throughout its lifecycle.

Conclusion

Your work environment will dictate which type of asset tags you’ll need, but if you want the best and most permanent solution, metal asset tags are the obvious choice.

They will provide you with the necessary protection from moisture, extreme temperatures, and strong chemicals, so you’ll be able to read your labels for years to come.

Some types of metal tags are better suited for indoor spaces, while others will fare better in outdoor environments. Some will degrade faster when exposed to rain, while others will stay intact in extremely high temperatures.

All of these factors need to be considered, but your best option is to ask a reputable company to customize your asset labels according to your specific needs.

Contact GoCodes Asset Tracking today to get the right solution for your asset tags and management!