Maintenance Management Resources

Equipment Maintenance: 5 Best Practices to Follow

Want to improve your equipment maintenance routine? This article will walk you through five best practices that keep operations smooth.

Equipment Maintenance: 5 Best Practices to Follow

Want to improve your equipment maintenance routine? This article will walk you through five best practices that keep operations smooth.

How to Reduce Equipment Maintenance Costs

Want to reduce equipment maintenance costs? This guide will show you practical strategies that lower expenses and improve asset performance.

Preventive Maintenance Checklist: What You Need to Know

In this article, you’ll learn how to build and use a preventive maintenance checklist to keep your equipment running longer.

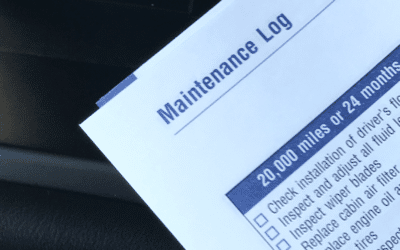

Equipment Maintenance Log: A Complete Guide

Tracking equipment issues manually? This article will teach you how a structured log can streamline your maintenance operations.

Equipment Scheduling & Booking Software: Our Top Picks

Explore our list of software solutions for scheduling and booking construction equipment, including their pros, cons, and key features.

How to Track Equipment Maintenance

Let this article provide you with the steps you need to take in order to successfully keep track of your equipment maintenance.

Best Practices for Equipment Maintenance Tracking

Join us as we explore the best practices for equipment maintenance tracking in construction.

Equipment Inspections Checklist: The Full Guide

Wondering why you need equipment inspection checklists, how to create them, and what to include? In this guide, we’ll answer all of those questions.

Equipment Inspections: 5 Best Practices to Follow

Discover best practices to follow for equipment inspections. This article covers them in-depth so you can implement in your own business.

The Ultimate Guide to Equipment Maintenance Software

Looking for the ultimate guide to equipment maintenance software? Learn how to choose the right software for your maintenance needs in this comprehensive guide.

10 Important Benefits of Using Equipment Maintenance Software

We’ll explores 10 important advantages of implementing equipment maintenance software, including improved efficiency, reduced downtime, and increased productivity.

7 Important Benefits of Work Order Tracking

In this article, we’ll go over some important work order tracking benefits.

Work Order Tracking Best Practices

This article will discuss five best practices for tracking maintenance work orders for equipment in the construction industry.

Importance of Equipment Inspections

You will learn all about the importance of equipment inspections and why they are a good addition to your equipment management strategy.

How to Keep Track of Equipment Inspections

We’ll explore five key actions that will allow you to streamline the tracking of equipment inspections.

Guide to Equipment Inspections

We’ll cover benefits of regular equipment inspections, as well as explain what they should cover and how often they should be conducted.

7 Benefits of Preventive Maintenance for Construction Equipment

This article will discuss seven benefits of preventive maintenance for construction companies.

Key Facts and Statistics on Equipment Maintenance

When equipment breaks down, companies suffer excessive downtime and are left with substantial repair costs. The best way to avoid both is to maintain your equipment regularly. In this post, you’ll find the key facts and statistics to help you understand the importance of adequate equipment maintenance. The Global Maintenance Market Is Predicted To Reach The Value Of $701.3 Billion By...

Tips to Improve Equipment Maintenance Safety

Equipment maintenance is a must for any company that deals with numerous assets. You have to know what condition your equipment is in to avoid any kind of injuries or risks in the workplace—and you can do that through maintenance. But how do you ensure safety for your maintenance team? We’ll explain what risks your upkeep team faces daily and how to structure your maintenance...

What are Equipment Maintenance Goals?

What are the most important equipment maintenance goals, and how do they affect your business? Read on to keep your staff, equipment, and business safe.

Equipment Maintenance Key Performance Indicators (KPIs)

Equipment maintenance KPIs are a step towards reaching your goals, no matter what kind of company you’re leading. They help you understand what you need to do to improve your company’s performance. First, however, you have to ensure that each KPI relates directly to a goal and that it is measured using specific metrics. This article will explain what maintenance KPIs are, how you can...

Super Simple Guide to Equipment Maintenance Metrics

Maintenance metrics measure the success of servicing and equipment, how long it takes to fix a malfunction, or how much time passes between breakdowns.

Equipment Disposal Guide: How to Remove What You No Longer Need

Every asset eventually reaches the end of its life cycle. Once the asset no longer serves its intended purpose, slows down significantly, or costs you more than it is worth, it is time to replace it. This article is for any company that has to dispose of equipment. It will explain when the time is right for disposal, what to do before it, and how to get rid of assets while saving...

Types of Maintenance: Different Strategies Explained

Understanding different types of maintenance and various strategies of undertaking and tracking them enables a company to make the most of its assets. This information is especially useful for COOs of companies with inventory or physical assets, businesses with a great deal of equipment, and businesses involved with fieldwork projects. Maintenance can be either preventive (also referred to as...

Tool Crib Management: Guidelines and Best Practices

If you’ve invested in a secure and well-stocked inventory of tools for your company, it makes sense to have a safe and organized place to keep them. A well-managed tool crib is significant for you as well as your employees and stakeholders. The importance of good tool crib management applies especially to the COO’s of companies with a wide range of physical assets or inventory. If your company...

How Technology is Changing Routine Equipment Inspections

If there's one thing a poor equipment maintenance strategy guarantees every time, it's unplanned downtime, which, according to recent estimates, can cost a business hundreds of thousands of dollars per hour. While routine asset inspections can mitigate that, gone are the days when the best such plans involved engineers wandering about facilities or plants looking for the right item to repair,...

Five Best Practices for Annual Equipment Inspections

Equipment inspections involve multiple processes and can be a time-consuming task to perform every year. Regular annual inspections are critical to the core of any business and have far reaching consequences on both short term and long-term growth of the company.Why Carry Out Annual Inspections?Annual inspections enable detection of minor wear and tear or any other defects that can lead to...

Coordinate and Track Equipment Maintenance and Inspections Using an App

Regardless of the industry, chances are good that you rely on some sort of equipment to do your job. Maintaining and inspecting that equipment is vital to your success; after all, you can’t perform a service with equipment that doesn’t work as it should. These days, a simple smartphone app can help you coordinate and keep track of equipment maintenance and make your job a lot...

How do you cut the cost of tracking equipment maintenance?

Equipment is the biggest investment for many companies. It’s a powerful incentive to engage in regular preventive maintenance to extend the useful life of that equipment, and it helps save money and improve the financial position of the company. Tracking maintenance may also help prevent potential liability for incidents related to inadequately maintained equipment and regulatory...