If you’re looking for a great way to track your assets and prevent equipment theft, labeling is the way to go. It seems that US contractors are already in on this, as 42% of them say they will be tagging their assets by 2022.

The labeling part is relatively easy: you attach a tag with identifying information onto your machinery. You can stick these labels onto practically any type of equipment, ranging from the smallest tools to heavy machinery.

The biggest question is, how to choose the right type of material for your labels?

This article will list the four most common materials used for tags and explain the benefits and downsides of each one to make your decision easier.

In this article...

Polyester Labels

Polyester labels are small tags made of polyester that are usually digitally printed. Barcode readability is ensured since the label comes out of the printer smooth and clean.

In general, they are used to tag assets for identification and theft prevention purposes, like other labels of that kind.

The backing of polyester labels is adhesive, so you can attach them to tools, heavy equipment, or office supplies with ease.

Such labels should withstand harsh environments, like exposure to rain and sun or even liquid substances such as grease, oil, and alcohol. Polyester tags are usually abrasion-resistant, which means they are durable.

However, such tags shouldn’t be exposed to high temperatures for a long time. If they are, the adhesive backing might get loose.

However, even though it’s not recommended to use them in high temperatures for prolonged periods, polyester labels can withstand temperatures up to 250°F.

Such labels should last for at least two to three years, even as much as seven under the right conditions.

Of course, if you keep exposing the label to high temperatures or different hazardous environments, they will last less.

The ideal environment for such labels consists of indoor spaces, such as your offices or the warehouse. They are typically used for paper files, office inventory, or other types of indoor equipment.

However, you can attach polyester labels to tools and equipment you use outdoors, too, even though it’s not recommended to use them out in the open for too long.

The benefits of using polyester labels include the following:

- They can conform to all types of surfaces.

- They are waterproof and chemical-resistant.

- Subsurface printing gives an additional protection layer.

- Because of the material, there’s no need to laminate the label.

- Easy to print in different colors for easier recognition.

- Their adhesive is usually permanent and extremely powerful.

However, polyester tags also have some downsides. Firstly, you can’t use them outdoors long-term, which means you can’t use them on all your equipment.

They are not as durable as some other types of labels, such as metal. Even though they can conform to different surfaces, they still lack flexibility, unlike other label materials.

Anodized Metal Foil Labels

Anodized metal foil labels are versatile due to their flexibility, ensuring they can be attached to a wide variety of surfaces.

On top of that, such tags are highly durable, thanks to the anodic seal layer. This additional layer protects the label against defacing, abrasion, and environmental damage.

At the same time, it doesn’t compromise readability: you still get maximum clarity and detail.

Labels made out of anodized metal foil can withstand harsh conditions, including chemicals, abrasion, solvents, and high temperatures. This makes them the perfect choice for challenging environments.

You can use anodized metal foil labels at up to 300°F in temperature. Anything over that can compromise legibility and loosen the tag.

Labels of this kind are incredibly durable and can last you a whole decade if you don’t subject the tags to extreme weather conditions or prolong their exposure to temperatures over 300°F.

The ideal application for metal foil tags is on equipment meant to be used in different environments.

In other words, you can use such tags on tools and assets that aren’t intended solely for outdoor or indoor use since they were made to withstand a variety of conditions.

So, you can use such labels to tag your office inventory, warehouse goods and equipment, and your field tools and equipment.

The benefits you get when opting for anodized metal foil labels are:

- Extreme durability that often helps the tag outlast the equipment

- Flexibility that makes it easier to attach the label to tools and equipment of various shapes and sizes

- Anodizing offers additional protection from chemicals, abrasion, and high temperatures

- Maximum adhesion

The only downside to metal foil labels of this type is that they can be fairly easy to remove, so they don’t offer as much protection from theft as other types.

Metal Tag Labels

If you want an incredibly durable label, opt for the metal kind.

These tags are permanent metal plates that you can attach or even mount to your equipment, which means they are tough to remove and impossible to alter.

However, keep in mind that the latter quality can be a challenge for companies that frequently update and change their labels.

Despite that, the durability and the material make metal tag labels perfect for harsh environments. You never have to worry about bad weather or dirt destroying them, and they offer good readability while being quite detailed.

Metal tags can withstand temperatures of up to 400°F, and even beyond. However, at 700°F, the readability of metal labels becomes limited.

Of course, certain tag manufacturers offer an optional process of intensification that maximizes heat resistance. If you choose to invest in this upgrade, the metal tags will withstand temperatures of up to 1000°F for short periods.

Metal tags can last you for decades, with some manufacturers reporting limited readability after 20 years. Still, even with this limitation in mind, metal tags are a reasonable investment.

The best part about metal tags is that you can use them in any kind of environment. You can use metal labels on tools and equipment both indoors and outdoors, and they’ll be equally valuable.

As you can see, metal tags are extremely versatile as you don’t have to switch between different types of labels for different kinds of machinery used by your company.

Using metal tag labels brings you the following benefits:

- They are extremely hard to remove or damage.

- This type of tag is impossible to alter.

- They are great for outside use.

- Because of the aluminum, such labels don’t rust and damage the equipment.

- They are very durable.

There are a couple of possible downsides to metal tags, depending on their primary purpose for your assets. Firstly, they can be expensive, but they are worth the money if you’re worried about theft and want to stop it.

Then, you can’t alter metal tags, so they’re not the right choice if the nature of your business compels you to update your labels often.

However, if you’re more worried about someone from outside of your company removing or altering your tag, metal ones are the perfect option for you.

Polycarbonate Labels

Polycarbonate is known for its flexibility, which makes it the perfect choice for an asset label. Though adaptable, the material is also strong and durable, so you can rely on its quality.

You can mechanically attach such tags to your equipment or use the adhesive to stick them on your tools. Either way, the labels will fit on any type of surface, so you can use them for more kinds of equipment.

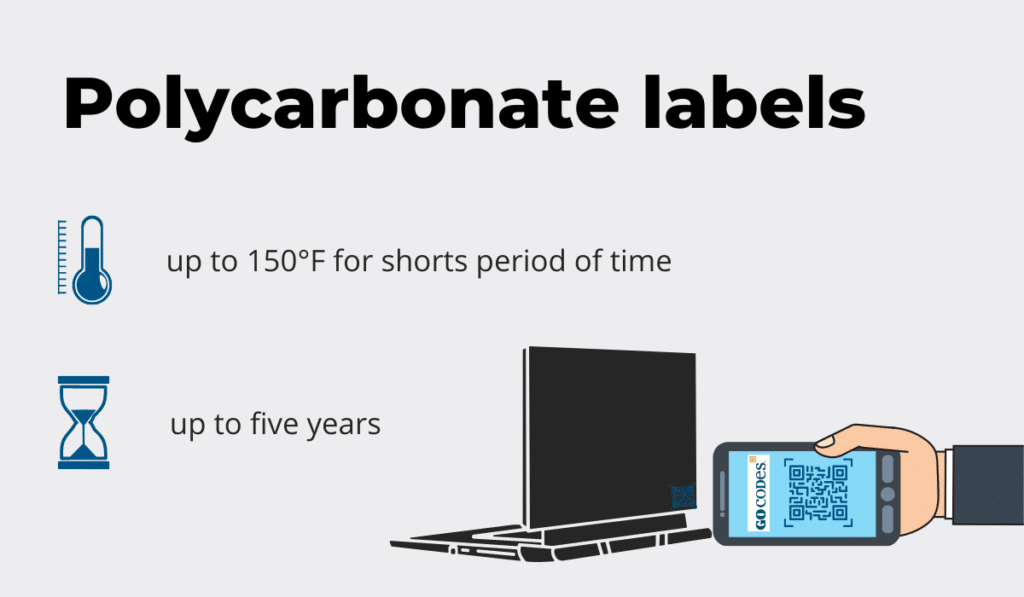

However, polycarbonate asset tags are not suitable for higher temperatures. You can use them in temperatures up to 150°C, but only for limited times if you want them to stay intact and perfectly readable.

Labels made out of polycarbonate should last up to five years, which means you won’t have to invest in new tags that often.

You should use polycarbonate labels indoors. However, this doesn’t mean the labels aren’t durable. Quite the contrary, such tags are resistant to stains, abrasion, moisture, corrosive chemicals, heat, and flames.

Therefore, you can use them for your office inventory, indoor equipment, and warehouse tools.

However, keep in mind that long-term outdoor use of polycarbonate labels is not recommended.

You benefit from using polycarbonate for your labels in more ways than one, because the material is:

- water-resistant

- hard-wearing and durable

- resistant to corrosive chemicals, stains, heat, and abrasion

- offers greater impact resistance than polyester

The downside of polycarbonate labels, as already mentioned, is that you aren’t supposed to use them outdoors, at least not long-term. Therefore, if you use both indoor and outdoor equipment, you’ll have to use different kinds of tags for each.

What to Consider When Choosing a Label

When picking the perfect label, you’ll make the most informed decision if you consider:

- The environment you want to use it in

- The temperature in this environment

- The desired durability

Here’s a recap of all the essential characteristics for each type of label we’ve discussed:

| Polyester | Metal Foil | Metal | Polycarbonate | |

| The environment | indoor environment | indoors and outdoors | indoors and outdoors | indoor environment |

| Service temperature | up to 250°F | up to 300°F | up to 400°F | up to 150°F |

| Durability | 2-3 years | Ten years | Multiple decades | Five years |

Based on these criteria, you’ll be able to decide between polyester, polycarbonate, metal foil, or metal tag labels. Each of these options brings you certain benefits, but each also has at least one downside.

Which one suits your needs best?

Conclusion

Tagging and labeling are an important part of asset management as they allow you to keep track of your possessions easily, preventing loss or theft.

And just like there are different kinds of assets you might want to track, there are many types of tags you can use on them.

Apart from the type of asset, your choice of material for the tag will depend on the environment you use it in and how long you want the tag to be legible.

We hope our guide proves useful in helping you make the right decision.