Trusted by 1,000+ businesses for the past 14 years

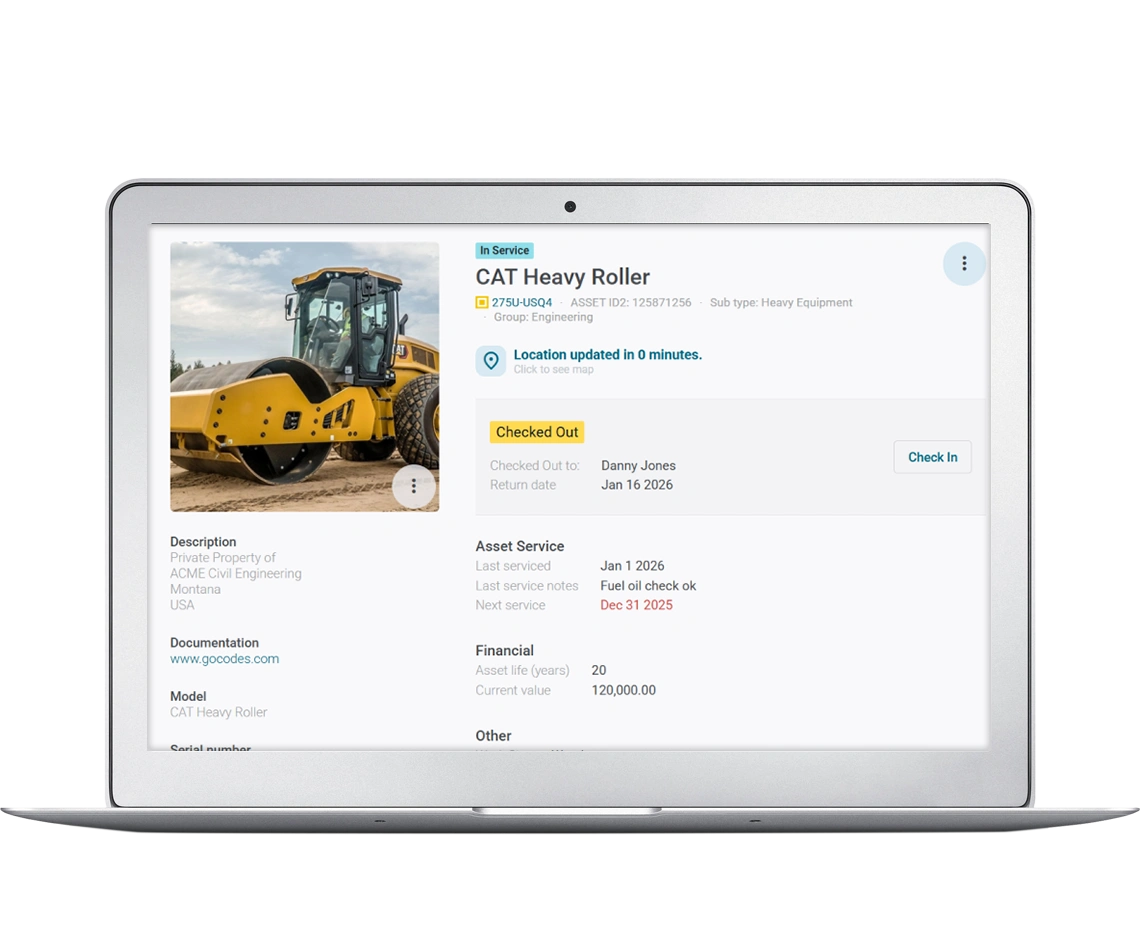

Asset Tracking That Understands Infrastructure Projects

DOT-Compliant Documentation

Generate audit-ready reports in seconds, not days

Multi-Project Visibility

See every asset across all active infrastructure sites instantly

No IT Infrastructure Required

Deploy in days with QR codes that survive concrete pours

The hidden cost of poor infrastructure asset management:

Civil engineering firms lose 15-20% of project margins to inefficient equipment management. When your survey crew drives to a bridge inspection site, only to discover the required testing equipment is 200 miles away at another project, you’re not just losing productivity, you’re risking contract penalties and compliance violations.

Equipment utilization rates below 40% while rental costs exceed $500,000 annually

3-5 hours weekly per project manager searching for equipment and updating spreadsheets

Compliance audit failures risk contractor prequalification status

Project delays average 2-3 days due to missing critical path equipment

Insurance premiums 20% higher without documented asset management protocols

Calibration Management Software Features and Capabilities

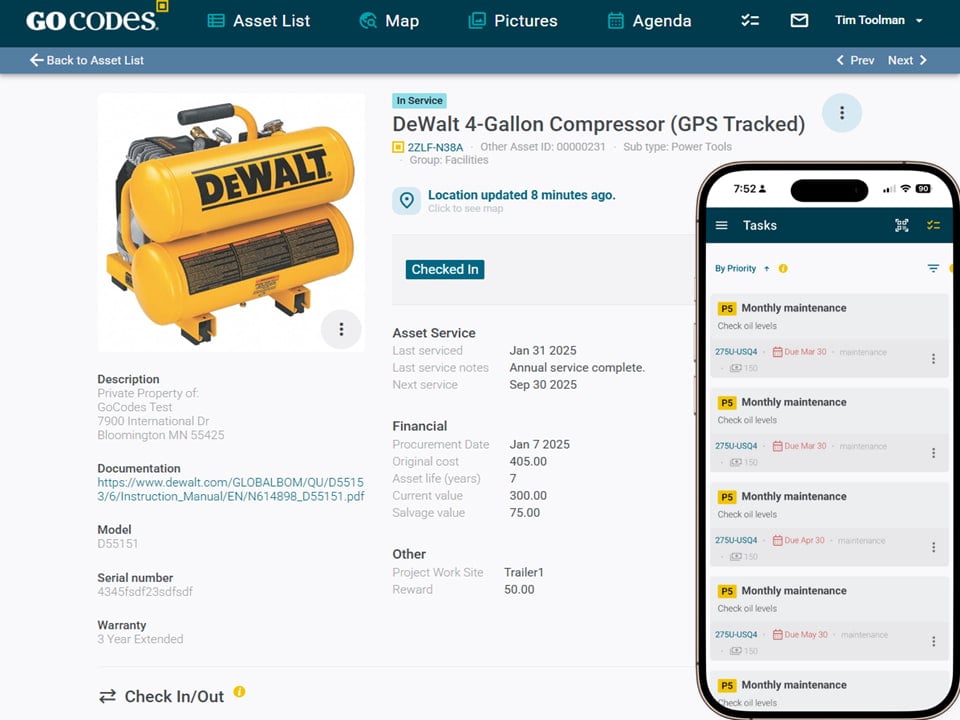

Lifecycle Management for High-Value Assets

Track your $75,000 total station from purchase through disposal, with complete service history, calibration certificates, and depreciation schedules integrated into your capital planning process.

Multi-Project Asset Allocation

Instantly see which boring rig is on the highway expansion project versus the water treatment plant upgrade. Schedule equipment moves based on critical path requirements, not guesswork.

Government Compliance Documentation

Generate DOT-required asset reports with one click. Maintain FHWA compliance for federally funded projects. Document equipment inspections per OSHA 1926 standards for infrastructure work.

GIS and CAD Integration Ready

Export asset location data for integration with your existing GIS systems. Link equipment tracking to project drawings and infrastructure mapping databases.

Real-Time Visibility Across Your Infrastructure Portfolio

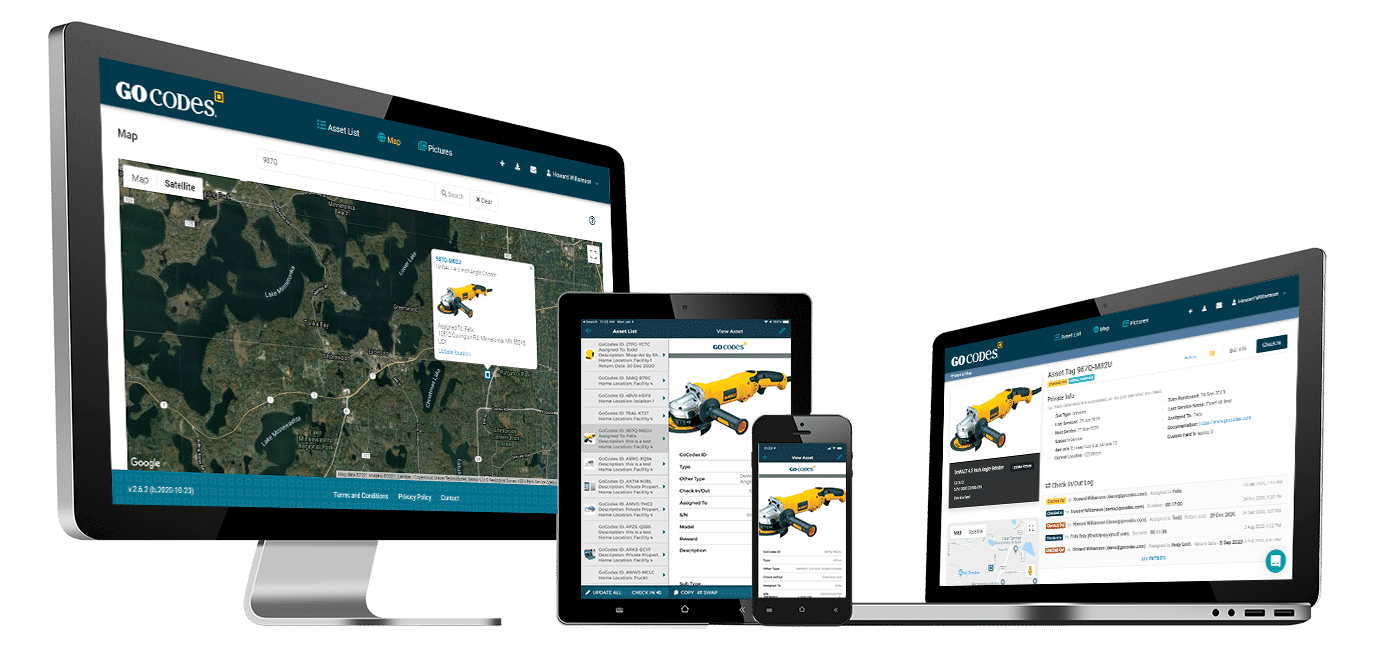

GoCodes delivers complete equipment visibility without the 6-month enterprise implementations that derail project schedules.

Intelligent asset tracking designed for field conditions

QR Codes That Survive Infrastructure Environments

Our patented metal QR tags withstand concrete pours, asphalt operations, and underground utility work. Unlike paper labels or plastic tags, they remain scannable after years of UV exposure, chemical contact, and extreme temperatures from -40°F to 200°F.

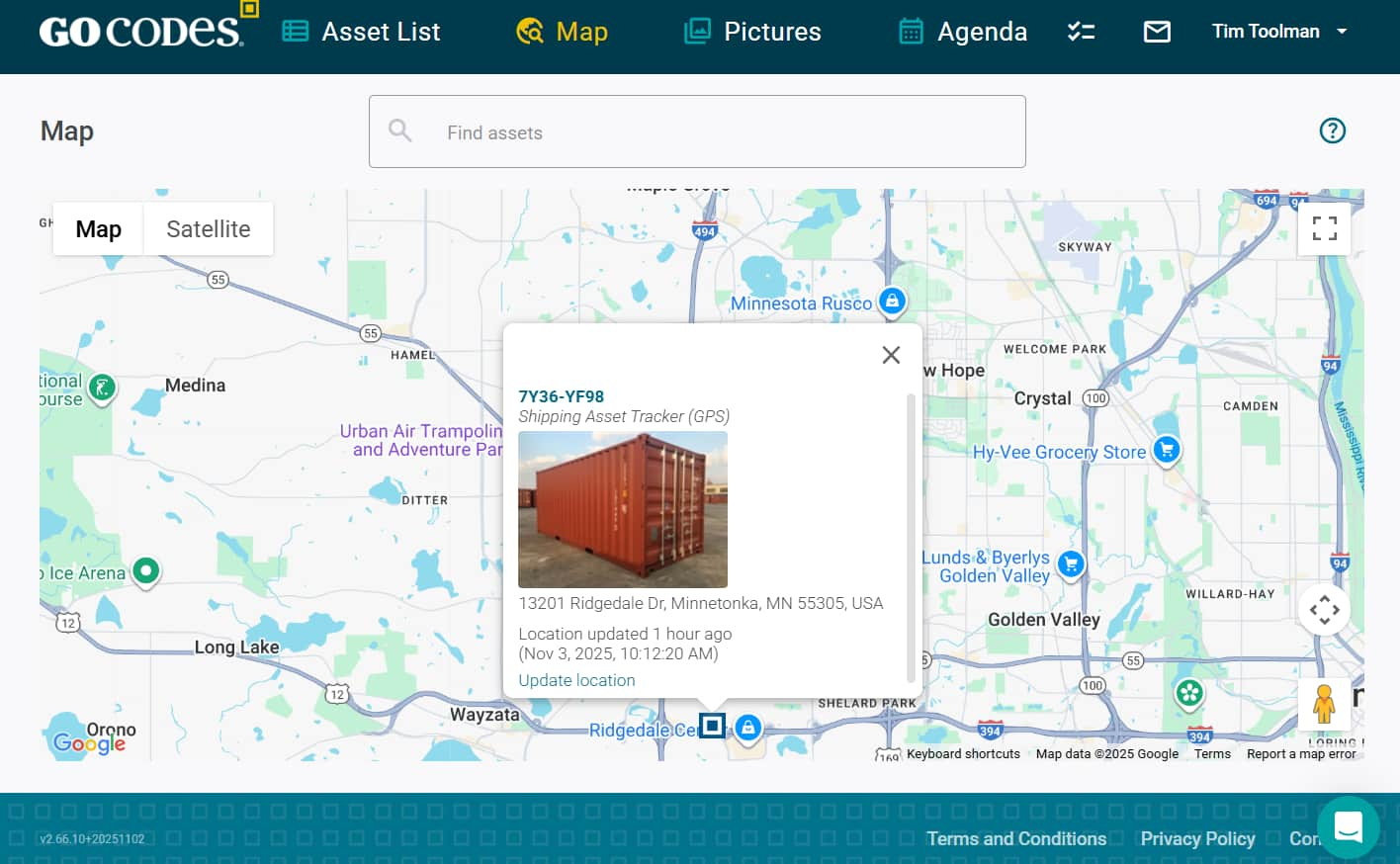

GPS Tracking for Mobile Equipment

Monitor your paving trains, drill rigs, and excavators in real-time. Set geofence alerts when equipment leaves project boundaries. Track operating hours for warranty compliance and preventive maintenance scheduling.

No App Downloads for Field Personnel

Scan QR codes with any smartphone camera – no special apps, no IT deployment, no training budget. Your survey crews and equipment operators adopt the system immediately because it works like taking a photo.

Compliance and Documentation That Passes Audits

Automated Inspection Reminders

Never miss crane certifications, confined space equipment checks, or fall protection inspections. The system alerts responsible parties, preventing work stoppages due to expired certifications.

Digital Chain of Custody

Track who used which testing equipment on specific infrastructure samples. Maintain legally defensible records for materials testing, soil analysis, and quality control documentation.

Instant Audit Reports

Generate equipment lists by project, funding source, or depreciation schedule. Export to Excel for GASB 34 reporting or integrate with your enterprise asset management system.

Built for How Civil Engineers Actually Work

Everything you need to start tracking inventory today. There’s no hidden costs and no expensive add-ons.

Field-first design philosophy

Project engineers managing interstate reconstruction don’t have time for complex software training. GoCodes deploys in days, not months:

- Tag and catalog 500 assets in one day with bulk import

- Instant Adoption – Field teams start scanning immediately with zero training

- Flexible Configuration – Customize fields for your specific compliance requirements

- Scalable Architecture – Add projects, crews, and equipment types without IT involvement

Professional

QR labels

GoCodes complements your existing infrastructure management tools:

- Export to existing systems via CSV, API, or automated reports

- Maintain current workflows while adding real-time visibility

- Preserve historical data with unlimited asset history retention

- Support hybrid tracking for transition from spreadsheets to digital

Tool Tracking ROI Calculator

How much money are you losing every year due to lost and stolen tools?

Key Civil Engineering Asset Management Features

Asset Tracking Features That Matter

Compliance and Documentation Management

DOT Certification Tracking: Automated alerts for equipment certifications, inspection deadlines, and safety compliance requirements. Generate audit-ready reports that meet state DOT and FHWA standards instantly.

Multi-Year Project Support: Track assets across decade-long infrastructure programs with complete historical data retention. Allocate equipment costs accurately across project phases and funding sources.

Chain of Custody Documentation: Maintain legally defensible records for materials’ testing equipment. Document who handled specific instruments for soil samples, concrete tests, and quality control verificat ion.

Integration and Reporting

Project Management Software Compatibility: Export data to Procore, P6, and Microsoft Project via API or CSV. Maintain single source of truth while feeding existing project workflows.

GIS/CAD Data Export: Integrate equipment locations with infrastructure mapping systems. Link asset tracking to project drawings and geographic information systems.

Custom Compliance Fields: Configure tracking for agency-specific requirements. Support federal, state, and local documentation standards without system modifications.

“These features transform civil engineering asset management from reactive spreadsheet tracking to proactive equipment optimization, ensuring infrastructure projects complete on time, within budget, and in full compliance with regulatory requirements.”

High-Value

Equipment Tracking

Surveying Instrument Management: Specialized tracking for total stations, GPS rovers, and levels with calibration history. Monitor $50,000+ instruments with tamper-evident seals and service records.

Heavy Equipment GPS Monitoring: Real-time location tracking for excavators, boring rigs, and paving trains. Set geofence boundaries for project sites and receive alerts when equipment moves unexpectedly.

Testing Equipment Control: Track specialized tools like core drills, compaction testers, and environmental monitoring devices. Schedule calibrations to maintain measurement accuracy for legal surveys.

Project and Resource Management

Multi-Site Equipment Allocation: View available assets across all active infrastructure projects instantly. Transfer equipment between highway expansions, bridge repairs, and utility installations efficiently.

Utilization Analytics: Identify underused equipment creating rental redundancies. Track actual usage hours versus available time to optimize fleet size and reduce costs by 30-40%.

Preventive Maintenance Scheduling: Automate service intervals based on operating hours, not just calendar dates. Prevent equipment failures that delay critical path activities and trigger liquidated damages.

Safety & Risk Management

Operator Certification Verification: Ensure only qualified personnel operate specialized equipment. Track training expiration dates and restrict access to uncertified users.

Incident Documentation: Record equipment-related safety events with photos and descriptions. Maintain comprehensive records for insurance claims and OSHA investigations.

Emergency Equipment Location: Instantly locate safety equipment, spill kits, and confined space gear during incidents. Critical for infrastructure projects with environmental and safety risks.

Field Operations Support

Offline Functionality: Continue tracking at remote project sites without cellular coverage. Data syncs automatically when connectivity returns, ensuring no gaps in equipment records.

No-App QR Scanning: Field personnel scan tags using any smartphone camera without downloads. Instant access to equipment manuals, safety sheets, and maintenance history from the job site.

Weather-Resistant Tagging: Metal QR tags survive concrete pours, asphalt operations, and extreme temperatures from -40°F to 200°F. Remain scannable after years of UV exposure and chemical contact.

Cost Control Features

Rental vs. Owned Analysis: Compare owned equipment costs against rental rates automatically. Identify when purchasing assets delivers ROI versus continuing rentals.

Project-Based Cost Allocation: Assign equipment expenses to specific infrastructure projects or cost codes. Support accurate job costing for fixed-price contracts and time-and-materials work.

Depreciation Tracking: Monitor asset values for GASB 34 reporting and capital planning. Plan equipment replacement cycles based on actual condition and utilization data.

Why Customers Choose GoCodes.

See Why Our Customers Rate Us!

GoCodes Asset Tracking

Case Studies

At GoCodes, we pride ourselves on facilitating meaningful asset management. But don’t just take our word for it. Learn how we have created impact for our satisfied users.

FAMILY LEGACY MISSIONS

Transforming Lives In Zambia

J&M Keystone

Flood and Damage Restoration

Articles & Insights

Information to give you more tracking power

10 Best Asset Tracking Softwares for 2026

In this guide we evaluate the 10 leading asset tracking platforms across multiple categories, from comprehensive hardware and software solutions to specialized IT asset management tools. So whether you manage a construction fleet, warehouse inventory, or enterprise IT...

The Full Guide to Check-In/Check-Out Software

Want to optimize your check-in and check-out process? Let our guide teach you how software can automate and simplify everything.

How to Find Stolen Construction Equipment

Discover how to find stolen construction equipment using modern tracking tools, best practices, and expert tips to boost recovery chances.

7 Asset Tracking Methods You Need to Know About

Want to improve how you track your assets? This article introduces 7 key asset tracking methods, with pros, cons, and use cases.

Why You Shouldn’t Use AirTags for Commercial Asset Tracking

Thinking about using AirTags to track business assets? This article explains why they’re not a good fit and what alternatives are better.

We include patented QR code tags that can be customized to your project. They come ready to use with our web software and smartphone scanner apps.

Works on devices you already own

Our FREE scanner apps and tags mean there's no hand-held barcode scanners or printers to purchase – so you’re up-and-running fast.

Frequently Asked Questions

Learn more about features, security, integration capabilities, and more!

What is Civil Engineering Asset Tracking Software?

Civil engineering asset tracking software is a digital platform that monitors and manages equipment used in infrastructure projects like highways, bridges, and utilities. It combines QR codes, GPS tracking, and mobile scanning to provide real-time visibility of assets from total stations to excavators. The software handles DOT compliance documentation, multi-year project tracking, and maintenance scheduling specifically required for civil engineering work. Unlike basic construction tools, it manages high-value surveying equipment and generates audit-ready reports for government contracts.

How Does Civil Engineering Asset Tracking Software Work?

Civil engineering asset tracking works in three steps:

- Tag Equipment – Attach durable QR codes or GPS trackers to assets

- Scan to Update – Field crews scan tags with smartphones to log location, user, and project

- Track Centrally – Cloud dashboard shows all equipment across project sites in real-time

The system automatically captures maintenance schedules, compliance certificates, and equipment history. GPS tracks mobile assets like boring rigs continuously. Data syncs when back online at remote sites. Project managers receive alerts for maintenance deadlines and generate DOT reports instantly.

What Are the Best Tool Tracking Solutions for Civil Engineers?

Top 5 Asset Tracking Solutions for Civil Engineering:

- GoCodes – Complete solution under $10K/year with QR codes, GPS, and DOT compliance. Deploys in days. Best for mid-market firms.

- Trimble – Enterprise platform with CAD integration. $100K+ investment with 6-month implementation. Best for large contractors.

- Tenna – Strong GPS tracking for heavy equipment. Limited surveying instrument support. Good for fleet-focused operations.

- ShareMyToolbox – Basic tool tracking at low cost. Lacks compliance features and lifecycle management. Suitable for small projects.

- Asset Panda – Flexible platform with custom fields. Requires significant configuration. Works for firms with IT resources.

Choose based on project scale, compliance requirements, and equipment mix. Most civil engineering firms achieve best ROI with purpose-built solutions like GoCodes.

How do you handle multi-year infrastructure projects?

GoCodes maintains unlimited historical data, allowing you to track assets across decade-long infrastructure programs. Project-based reporting lets you allocate costs accurately regardless of project duration.

How do you handle DOT and federal compliance requirements?

GoCodes includes customizable compliance fields, automated certification tracking, and audit-ready reporting formats accepted by state DOTs and federal agencies.

How quickly can we deploy across multiple active projects?

Most firms achieve full deployment within 2-4 weeks. Our implementation team has deployed systems for organizations with 10,000+ assets across hundreds of locations.

Can we integrate with our existing project management software?

Yes, GoCodes provides CSV export, API access, and automated reporting to share data with Procore, P6, Microsoft Project, or any system accepting standard formats.