Regardless of the size of the project your team is working on, the construction site is likely to get busy.

With construction workers buzzing around, and tools and equipment everywhere, the last thing your crew wants to worry about is finding outlets to plug in their tools or making sure they don’t trip over power cords.

Cordless power tools are a simple solution to these problems.

In this article, we are focusing on 8 different cordless power tools that are going to make work easier for your construction crew.

In this article...

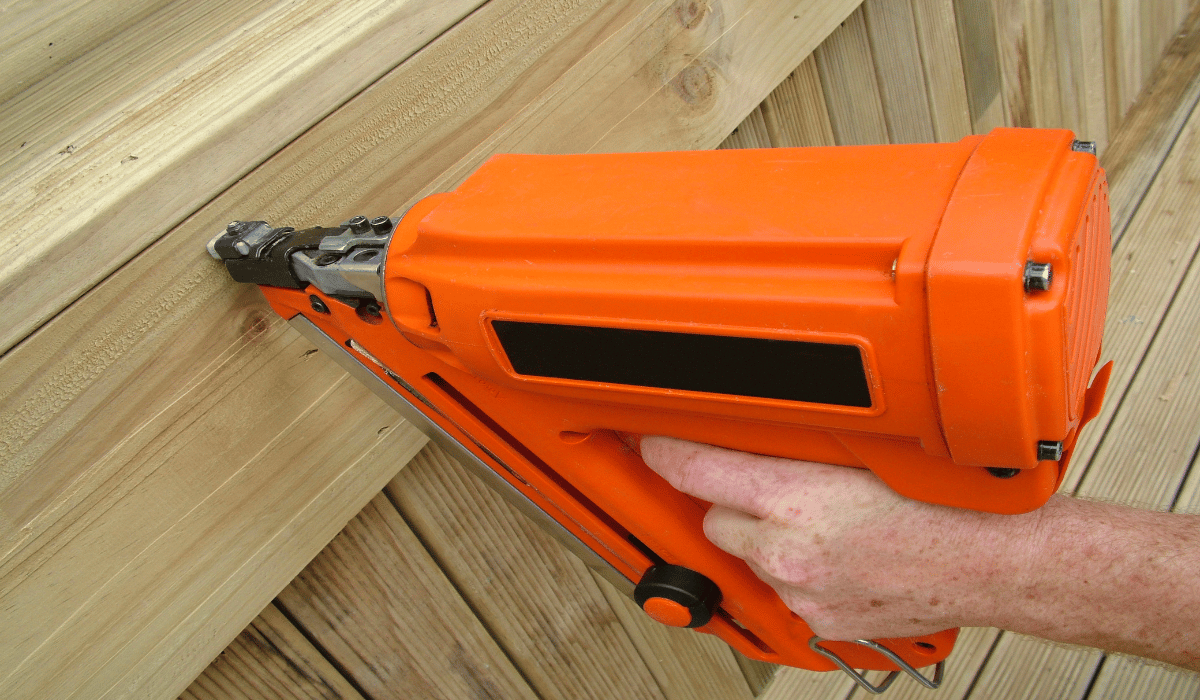

Cordless Nail Gun

A cordless nail gun is a must-have for construction work.

Also known as a nailer, a nail finisher, or a framing nailer, this cordless power tool is used more and more as a replacement for the hammer, for driving nails into wood or other materials.

Because they fire nails and nail them into the target as you pull the trigger, cordless nail guns can save your crew a lot of time that would otherwise be spent hammering.

They also reduce the risk of your crew hurting their fingers, as they might with the old-fashioned hammer.

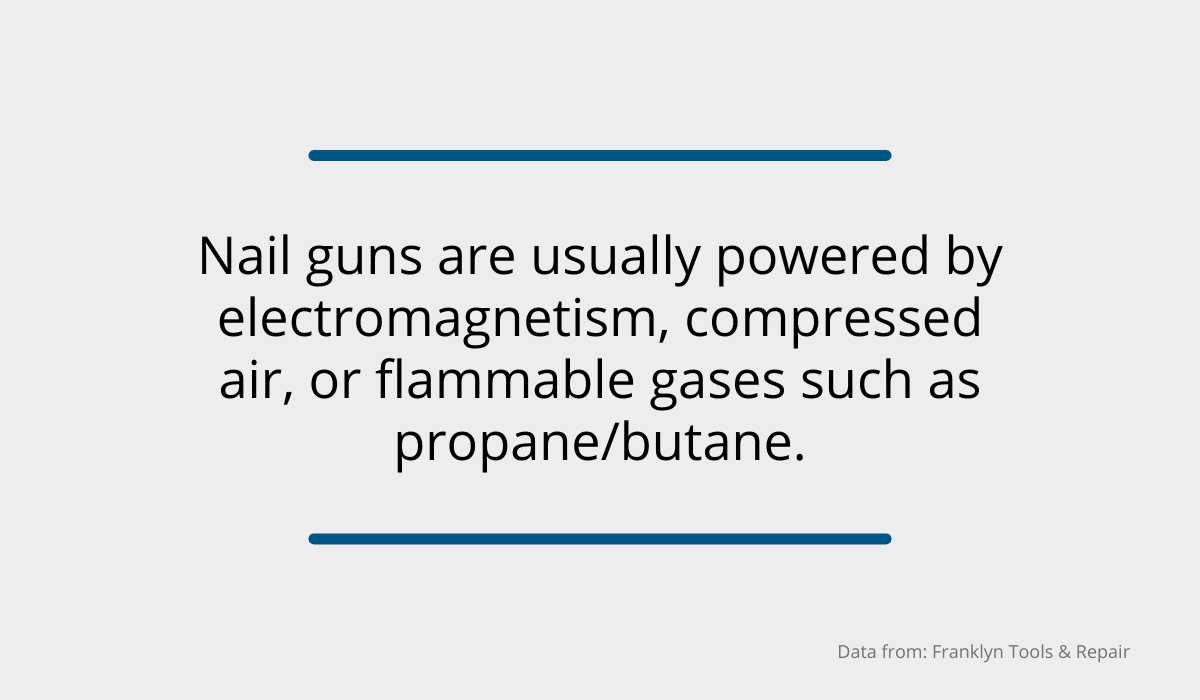

So, how do cordless nail guns actually work?

Most nail guns are powered by compressed air, so when the trigger is pulled, air pressure travels through the tubes and the barrel, pushing the nail out.

Apart from the fact that they make nailing things down quick and effortless, cordless nail guns are also extremely convenient, thanks to the very fact that they don’t have a cord.

This means that, when using them, your workers will be able to move around the construction site freely, without having to worry about tripping on the cord or not finding an outlet.

However, remember that a cordless nail gun can be dangerous if your workers don’t take proper precautions while operating it, so encourage them to use safety gear in order to protect themselves from debris and injury.

Cordless Drill

A cordless drill is another toolkit staple that will make work easier for your construction crew.

It is powered by rechargeable batteries and used for drilling circular holes, as well as driving screws and other fasteners into wood, metal, and various other materials.

While they are bulkier than their corded counterparts, cordless drills have the advantage of not restricting your crew’s mobility on the construction site.

An important feature to take into account when choosing the right cordless drill for your construction crew is the torque of the drill.

Torque is measured in Newton meters (Nm), and it is “a measure of how much rotational force a drill can produce.”

While those working on DIY projects or typical household tasks will need a cordless drill with up to 50 Nm (and even 25 Nm will often be enough for smaller projects), your crew will need a drill with more torque, i.e., above 50 Nm.

Nowadays, most cordless drills come with a side handle that needs to be attached to the drill.

The side handle will not only allow your workers to have a better grip while drilling, but also prevent kickback.

Kickback happens when the drill bit binds up in the material while drilling.

When that happens, if the worker isn’t using a side handle, they are at risk of wrist and arm injuries.

Therefore, it is important for you to encourage your crew to use this powerful and versatile tool with caution.

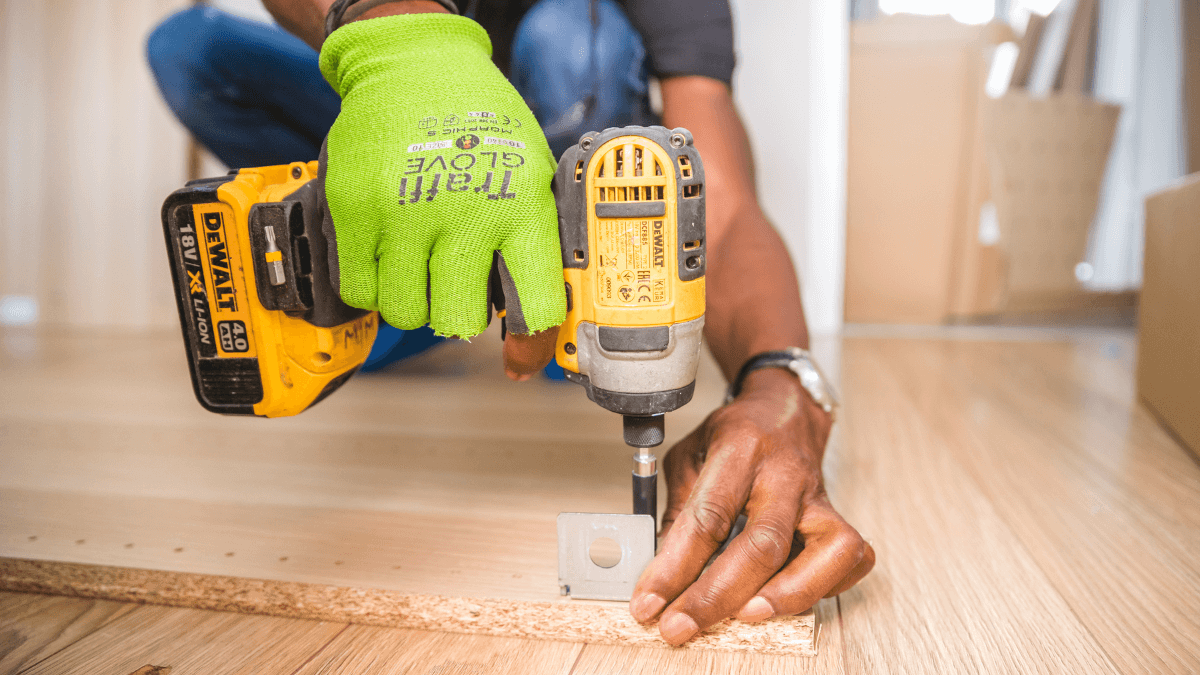

Cordless Impact Driver

A cordless impact driver is a tool that “uses rotational force to drive a screw and saves its bursts of quick power when it feels resistance.”

While it resembles a cordless drill, an impact driver has the ability to deliver more torque and handle larger screws and bolts.

That is one of the reasons why it’s a great tool to use for larger projects where a cordless drill might not be the best choice.

Furthermore, an impact driver uses less battery than a cordless drill, and it is smaller and lighter, so it puts less strain on the arm and the wrist.

Despite its advantages, a cordless impact driver does have a downside, too—the loud noise it makes when it’s being used.

If that is an issue for your construction crew, you may want to consider investing in a hydraulic impact driver, also known as a pulse driver.

Hydraulic impact drivers have the same advantages as regular cordless impact drivers, but they are quieter and even more powerful than impact drivers of the same size.

For example, the Ryobi 18-Volt ONE+ QUIETSTRIKE Pulse Driver is faster and more powerful than a drill, but 50% quieter than an impact driver, so it might be a good choice for your crew.

Cordless Hammer Drill

A cordless hammer drill is another essential drilling tool your construction crew is going to need.

Also known as a percussion drill, this power tool is “a form of the rotary hammer that uses an impact mechanism to generate a hammering motion.”

The hammer drill is often used for drilling holes in hard materials such as brick, stone, or concrete.

It is not a tool that your crew should use for putting holes in wood, plastic, or metal, though, as it would slow them down and cause unnecessary vibrations.

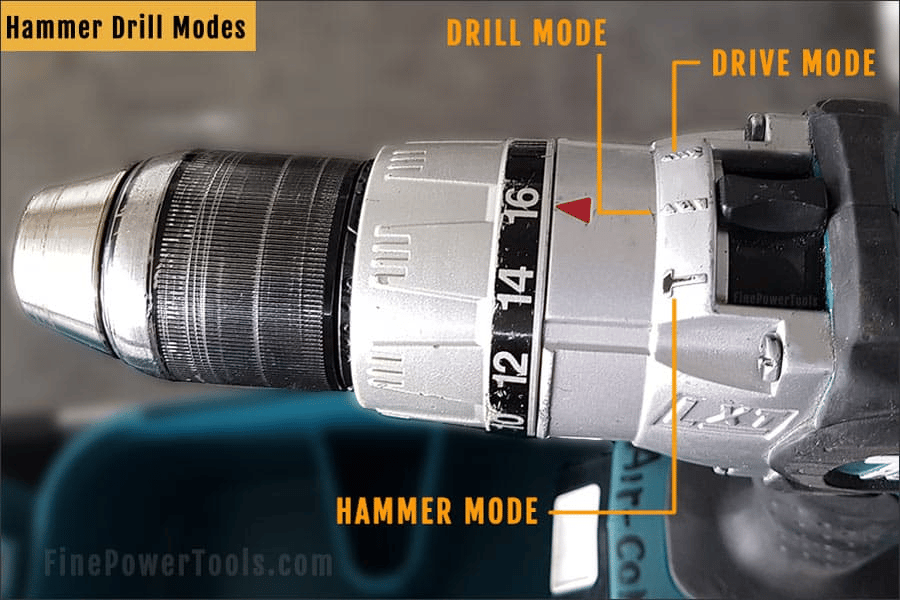

At first glance, a hammer drill looks very similar to a regular cordless drill.

However, a hammer drill consists of two sets of toothed gears that interact with each other to create a hammering motion while rotating the drill bit.

Keep in mind, however, that there are also cordless drills that come with a hammer mode.

When put in that mode, a pulsating action is added in order for the tool to be able to drill through hard materials.

Just like cordless nail guns, drills, and impact drivers, cordless hammer drills aren’t hindered by the power cord.

This means that they can come in very handy on contruction sites which don’t have an electric outlet.

Cordless Reciprocating Saw

If your construction crew needs a powerful tool to help with rough cutting jobs, a cordless reciprocating saw will come in handy.

A reciprocating saw, also known as a hognose or recip saw, has a blade at the front that moves back and forth, so the cuts are achieved through a push-and-pull (i.e., reciprocating) motion of the blade.

The foot of the reciprocating saw, located at the base of the blade, needs to rest on the surface that is being cut, and the saw needs to be held firmly during use.

By attaching different blades to this saw, your team will be able to effortlessly cut through different materials, from wood and metal to nail-embedded wood.

According to Lou Manfredini of Ace Hardware, with the reciprocating saw, “the rule of thumb is: the fewer teeth per inch, the faster and rougher the cut.”

So, keep that in mind when deciding what kind of blade you need for which task.

It goes without saying that protective gear is non-negotiable when using a reciprocating saw.

Make sure that your construction workers are wearing protection for their eyes and ears, as well as a dust mask while operating this powerful tool.

Cordless Jigsaw

A cordless jigsaw is the power tool that your crew is going to need for cutting both straight and more complicated, curved lines in wood, metal, and even drywall.

Just like the reciprocating saw, a jigsaw is also going to have the option of attaching blades with different heights and tooth counts, depending on the type of material that needs to be cut.

This compact, battery-powered tool uses a reciprocating saw blade that makes cuts in the material by rapidly moving up and down.

A cordless jigsaw works by placing the shoe (i.e., the base) of the jigsaw against the workpiece, which is then pulled against the shoe, while the blade cuts through the material.

Apart from making sure that the blade being used matches the type of material it needs to cut, it is also important to adjust the speed of cutting.

For example, higher speeds are more suitable for cutting wood, whereas plastic and metal can be cut on a slower setting.

Just like with the reciprocating saw, wearing protective gear is mandatory when using a cordless jigsaw.

It is also advisable to instruct your crew not to wear any jewelry while operating this tool in order to make sure it doesn’t get caught on it and potentially cause an injury.

Cordless Circular Saw

Another powerful tool your crew is definitely going to need at the construction site is a cordless circular saw.

Tools Owner explains that “the circular saw uses an abrasive or toothed disc or blade to make different cuts in material with a rotary motion that spins around an arbor.”

This type of saw comes with a variety of different blades that can be attached to it, depending on the kind of material that needs to be cut.

Whether it is cutting wood, plastic, or metal, this tool has the ability to make straight cuts as the saw is passed through the stationary piece of material.

In order to prevent injury and get clean cuts, it is important to keep the material that is being cut securely in place with the help of a sawhorse, for example.

Alternatively, Steve Ramsey of the Woodworking for Mere Mortals YouTube channel suggests cutting the material on the ground, on a piece of Styrofoam.

This method helps ensure a cleaner cut and prevents kickback.

Don’t forget to make sure your construction crew is staying safe while using a circular saw by encouraging them to wear protective glasses, earplugs or earmuffs, as well as a dust mask.

Cordless Angle Grinder

Lastly, it is recommended for your construction crew to have access to a cordless angle grinder.

As most tools on this list, a cordless angle grinder is powered by a rechargeable battery, so it’s convenient to use when away from a power source.

A cordless angle grinder is a versatile power tool that is used primarily for removing excess materials, grinding, sharpening, and polishing.

It can also, however, perform other tasks due to the fact that it allows for different attachments and types of cutters.

For example, you can attach a sanding disc to it in order to use the angle grinder as a sander.

Typically, angle grinders have a guard and a side handle in order to make them easier to control.

Using a cordless angle grinder requires caution, given that there is a risk of injury if not used properly.

To avoid getting injured, it’s important to angle the grinder correctly and allow it to reach its full speed before touching the work surface so that it doesn’t skip or bind up.

Apart from that, wearing hearing protection, a face shield, gloves, and a dust mask is necessary.

Conclusion

We hope that this list provided valuable insight into the benefits of using cordless power tools on the construction site.

Not having to worry about finding a power source or tripping on cords while moving around a busy construction site is sure to make your workers’ jobs easier.

Keep in mind that, although cordless power tools are convenient and easy to use, they can cause injury if not used properly.

So, make sure to keep emphasizing the importance of following safety precautions while using these tools.