Trusted by 1,000+ businesses for the past 14 years

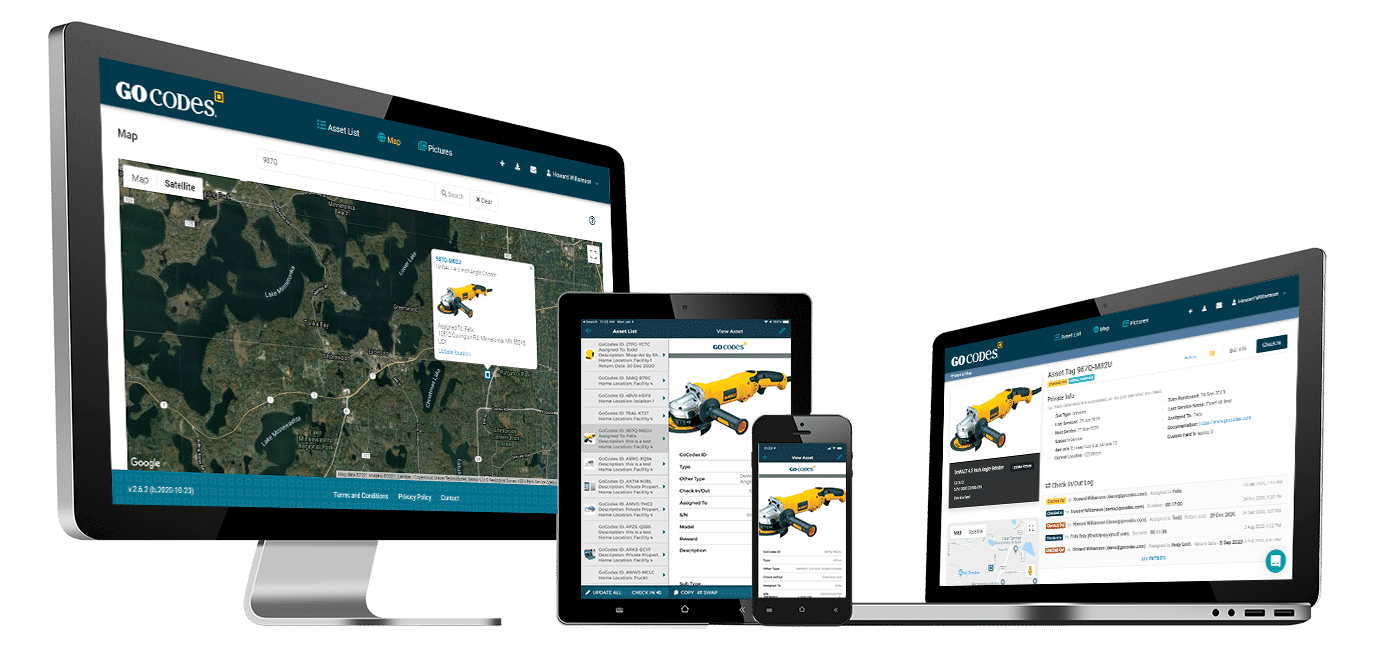

The Only Asset Tracking System That’s Actually Easy to Use

Implemented in days, not months

Start tracking equipment in under 2 weeks

Total solution software + hardware

Software + mobile apps + free QR code labels

Complete asset visibility

Know where every asset is and who has it

The tool tracking problem every contractor faces

Tool replacement eats 15-20% of your equipment budget. Crews waste time hunting for tools. Projects delay because equipment isn’t where it should be. And you’re buying duplicates of tools you already own and don’t need.

Tools Walk Off Jobsites

Spreadsheets Can’t Keep Up With Field Reality

Nobody Knows What Equipment Is Where

Your Accounting System Doesn’t Track Physical Assets

Maintenance Gets Skipped Until Equipment Fails

GoCodes gives you real-time asset visibility, crew accountability and preventive maintenance automation. All accessible from your teams’ smartphones.

How GoCodes Tracks Construction Equipment Across Jobsites

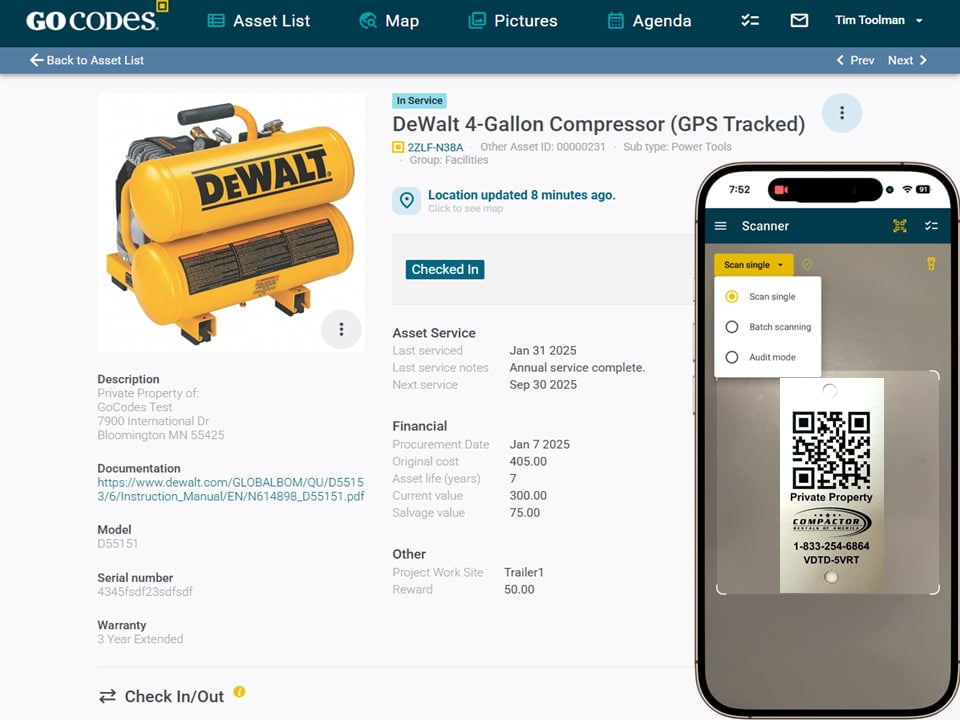

Scan QR codes with any smartphone

Every asset gets a rugged QR code label designed for construction environments:

- Metal tools: Poly labels withstand impacts, chemicals, and outdoor exposure

- Heavy equipment: Metal foil labels survive high-heat, vibration, and UV exposure

- Vehicles & trailers: Rigid aluminum tags mount permanently with tamper-evident fasteners

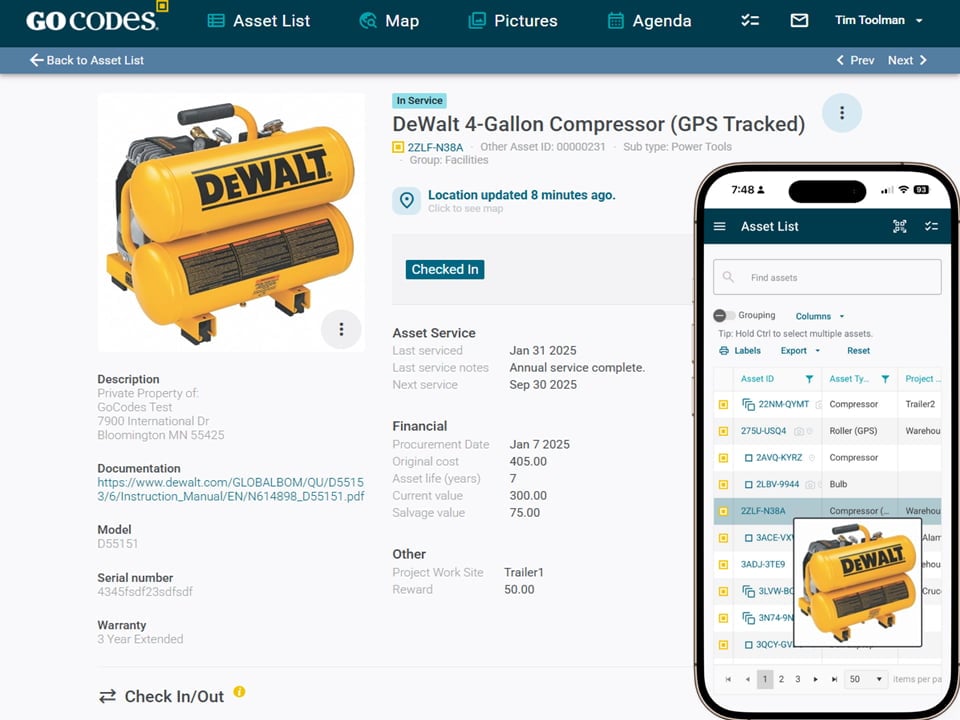

Foremen scan tools in/out using the free GoCodes’ mobile app that works on any iPhone or Android device. No expensive barcode scanners. No special hardware. Just the phones your crews already own.

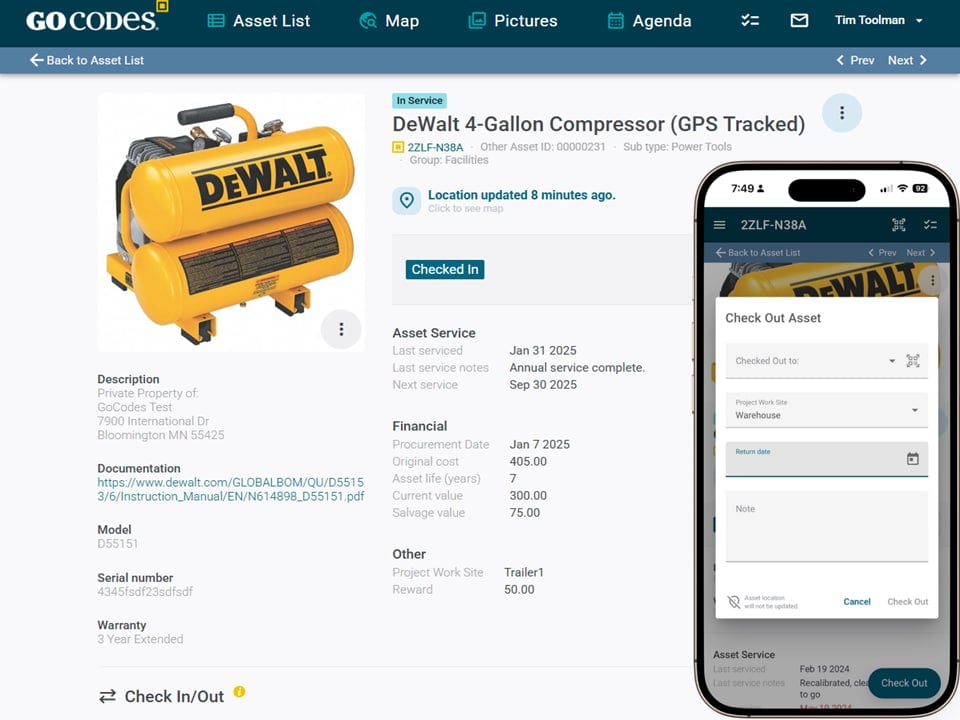

Check-in/check-out creates crew accountability

Every tool movement generates an audit trail:

- Who took the rotary hammer to the Westside project

- When the welding equipment left the shop

- Which foreman signed out the $12,000 laser transit system

- Where your generator was last seen before it disappeared

Crews scan tools out when loading trucks. Then scan back in when returning equipment. The mobile app captures GPS location, timestamp, and employee assignment automatically. No paperwork. No manual logs. Just tap, scan, track.

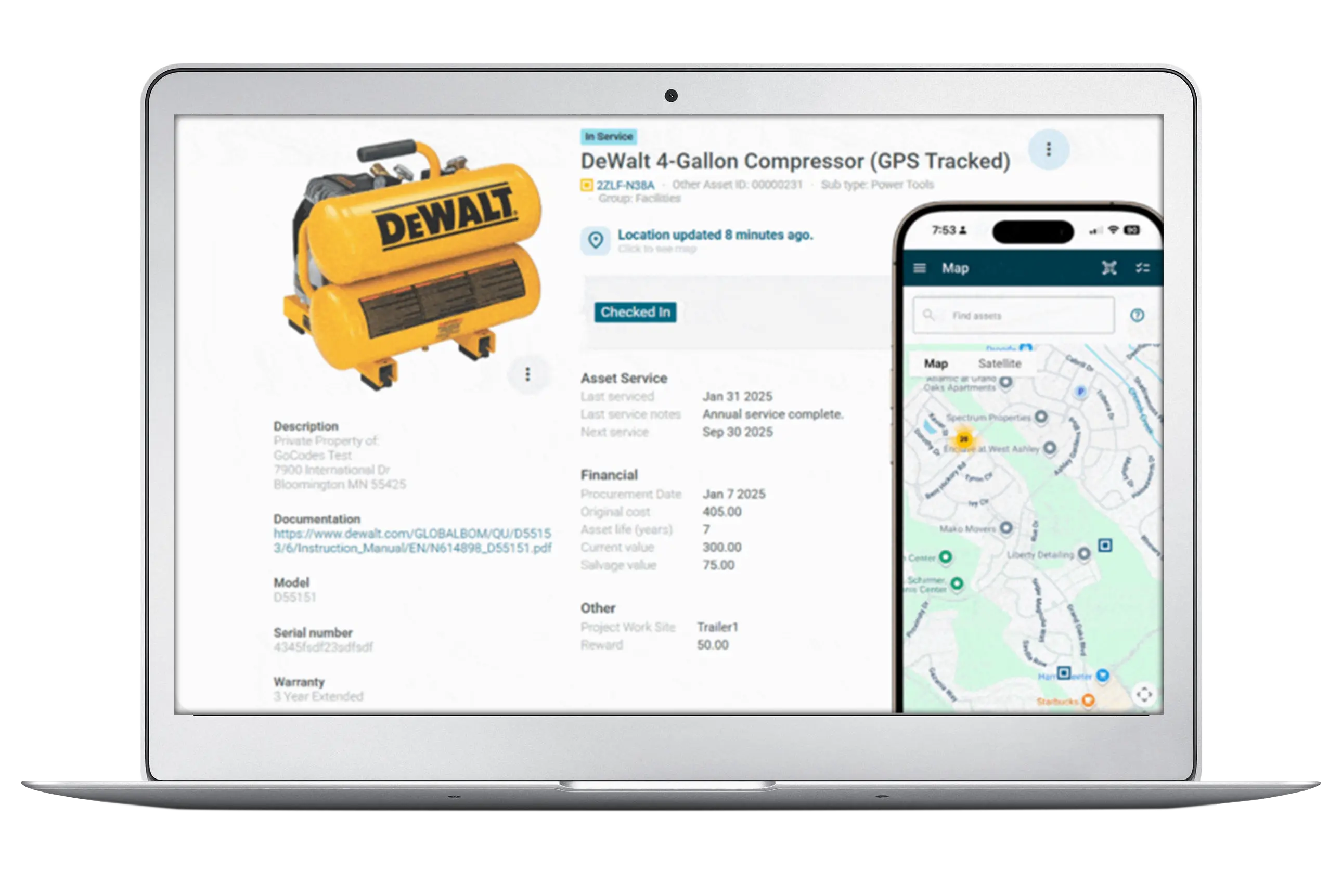

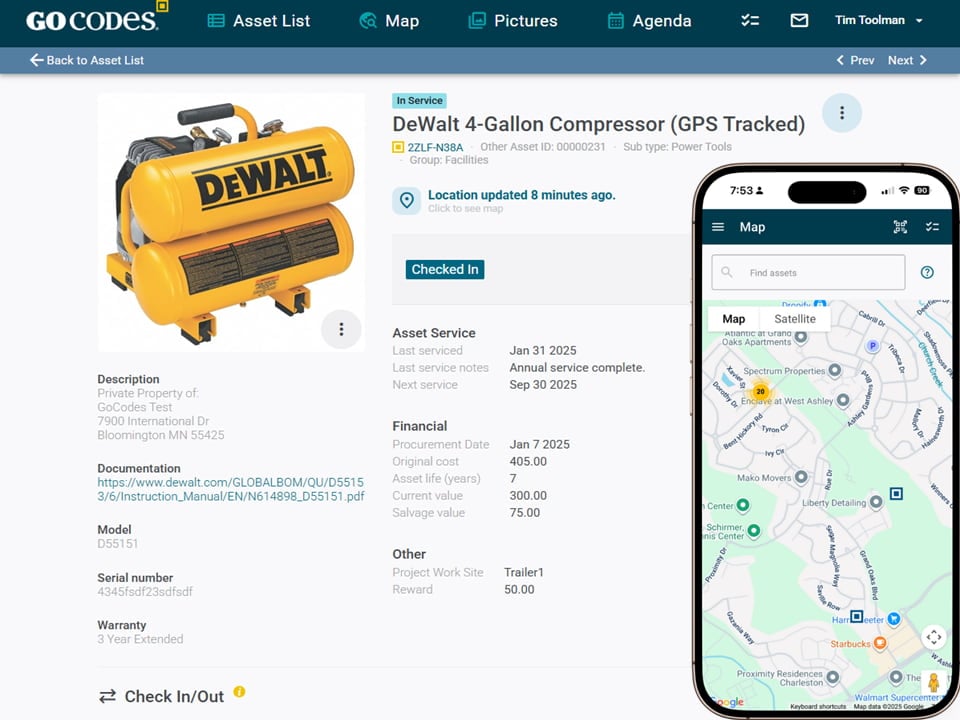

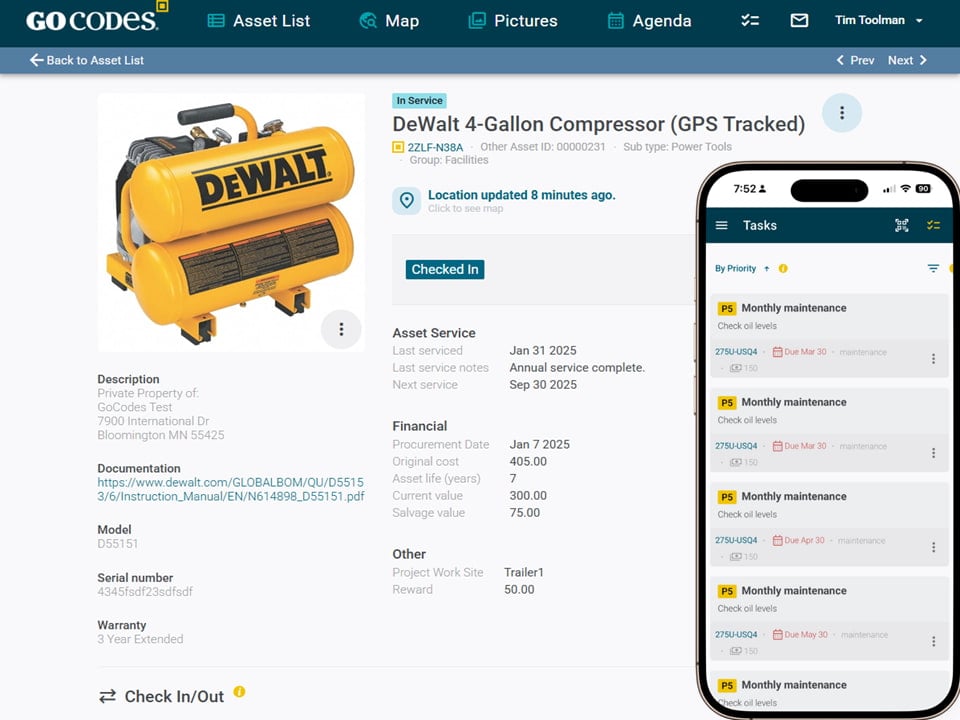

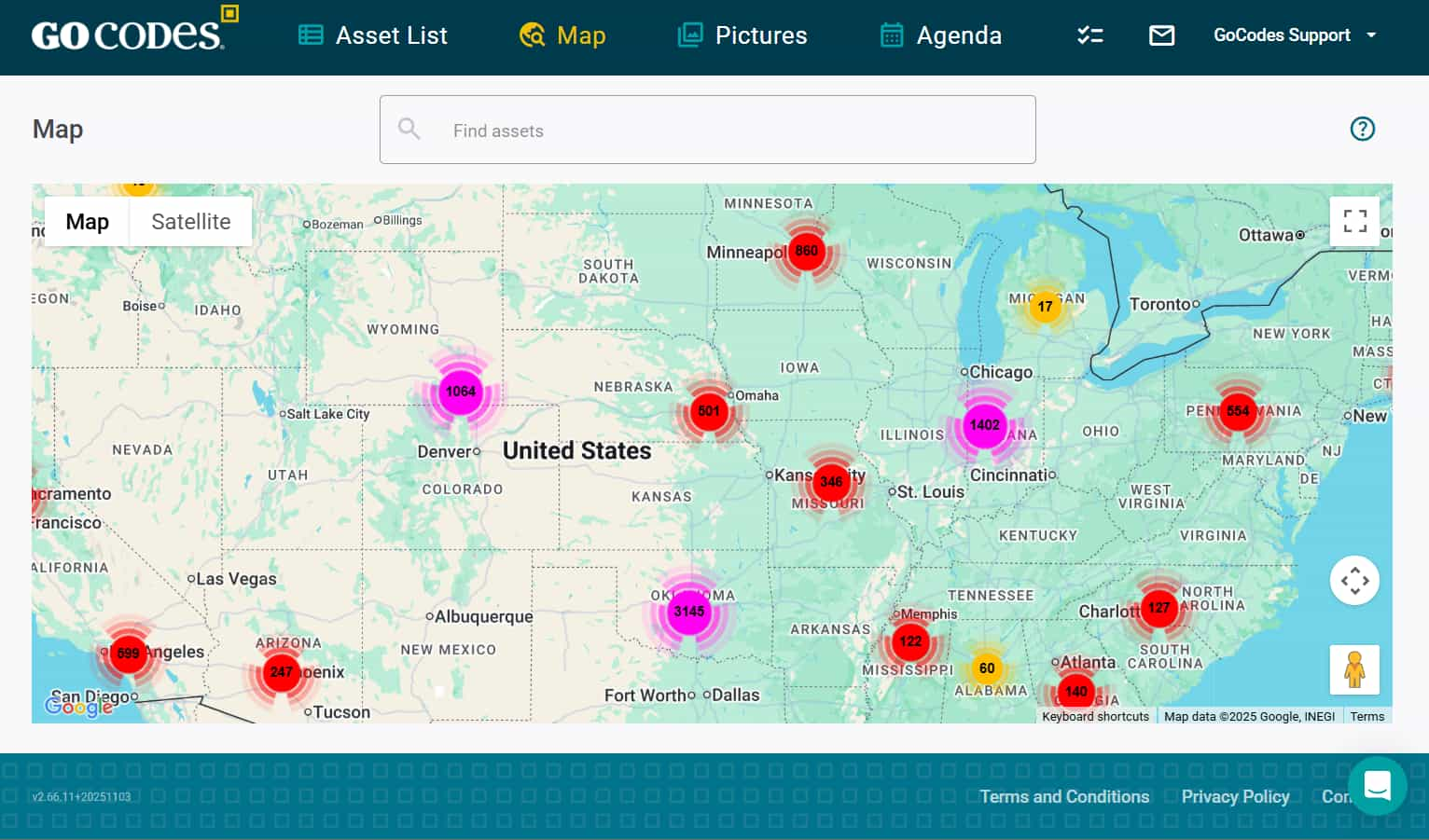

Real-time GPS tracking for high-value equipment

Add GPS trackers to critical assets for live location monitoring:

- Track excavators, skid steers, and heavy equipment 24/7

- Get theft alerts when equipment moves outside geofenced jobsites after hours

- Locate “lost” generators and compressors instantly from your office

- Monitor vehicle fleets and trailer locations across project sites

The GPS data integrates with your QR code tracking in one system that shows everything from $50 drills to $50,000 excavators. No switching between platforms.

Automatic maintenance scheduling that prevents equipment failures

Set maintenance intervals by your usage cycle (daily/weekly/monthly):

- Service excavators every 250 engine hours

- Inspect fall protection equipment every 90 days per OSHA requirements

- Replace saw blades after 100 cuts

- Recertify welding equipment annually

GoCodes calculates next service dates automatically. Send automated maintenance reminders to equipment managers. Track service history for warranty claims and compliance documentation. Never miss preventive maintenance that extends equipment life.

ROI insight: A $35,000 skid steer properly maintained lasts 12,000 hours. Neglected, it fails at 6,000 hours. Maintenance tracking extends equipment life by 5-7 years, deferring a $35,000 replacement cost.

Mobile-first design your crews will actually use

Built for construction field teams, not office administrators:

- Offline mode: Scan and track even without cell service then syncs automatically when back online

- Glove-friendly interface: Large touch targets work with work gloves on

- Fast scanning: Check-in/check-out takes 3 seconds per tool

- Photo documentation: Capture equipment damage photos tied directly to asset records

- Voice notes: Foremen add audio notes about equipment issues without typing

The app works on dusty touchscreens, in bright sunlight, and with gloves. Designed for real job site conditions.

Dashboards give project managers equipment visibility

See exactly what equipment is on every project:

- Which tools are checked out to what project

- What equipment is sitting unused at the warehouse

- Which jobsites are over-equipped vs. under-equipped

- Asset utilization rates across your entire fleet

Rebalance equipment between projects without calling on foremen. Identify underutilized assets that should be sold or rented out. Stop buying duplicate equipment because you didn’t know you already owned it.

Construction manager workflow: Opens dashboard Monday morning. Sees that 3 jackhammers sit unused at a completed project. Reassigns them to an active demolition site starting that week. Avoids a $6,000 rental cost.

Stop Tool Theft and Equipment Loss With Digital Accountability

Assign personal responsibility for every asset

The #1 reason contractors lose tools: Nobody feels personally responsible for equipment that “belongs to the company.”

GoCodes changes this by creating digital accountability:

- Tool checkout system: Employees scan out tools under their name, they can’t claim “I didn’t know I had it”

- Daily verification: Foremen verify all checked-out equipment before leaving jobsites

- Missing item alerts: Automated notifications when tools don’t return within expected timeframes

- Historical assignments: Full audit trail shows every person who handled an asset

Reduce equipment theft with visible tracking labels

Deterrence works. Visible GoCodes labels signal that equipment is tracked and monitored.

Layer security measures:

- Physical labels: Visible deterrent + identification if stolen equipment surfaces

- GPS tracking: Real-time location for high-value equipment movements

- Geofencing alerts: Notifications when equipment leaves jobsite boundaries after hours

- Police reports: Asset records with serial numbers and photos speed recovery efforts

Recover stolen equipment faster with asset records

When equipment gets stolen, having complete documentation improves recovery odds:

- Serial numbers: Police reports require serial numbers for stolen property tracking

- Photos: Visual identification if equipment surfaces at pawn shops or resale sites

- Purchase records: Proof of ownership for insurance claims

- GPS last-known location: Narrows search area for recovery efforts

GoCodes asset profiles store all this information automatically. When a theft occurs, you have everything law enforcement needs within 30 seconds. Data isn’t scattered across purchase orders, receipts, and Excel files.

Eliminate the “left at customer site” problem

30% of “stolen” tools aren’t actually stolen, they’re left at completed jobsites.

GoCodes checkout process prevents this:

- Foremen scan all equipment checked out to a project before crew leaves

- System flags any tools not scanned back in

- Immediate verification: “We brought 12 tools to this site, where are they?”

- GPS timestamps prove when equipment last checked in at jobsite

You catch missing equipment the same day, while crews still remember where they left it. Not 3 weeks later after tools have been lost, stolen, or mistakenly kept by customers.

Equipment Lifecycle Management From Purchase To Disposal

Track every asset’s complete journey:

Maintenance:

- Schedule preventive maintenance by hours, days, or usage

- Track service history, parts replaced, and maintenance costs

- Store service records for warranty claims and resale documentation

Disposition:

- Identify underutilized equipment for sale or rental income

- Track disposal or sale proceeds

- Maintain historical records for audit compliance

Depreciation:

- Calculate equipment depreciation for financial reporting

- Export asset data to QuickBooks or other accounting systems

- Generate fixed asset reports for tax purposes

Deployment:

- Assign equipment to specific projects, crews, or locations

- Track utilization rates: Which assets are heavily used vs. sitting idle

- Calculate project-based equipment costs for accurate job costing

Procurement:

- Record purchase date, vendor, purchase price, and warranty information

- Attach invoices and purchase orders directly to asset records

- Track equipment specifications and model numbers for parts ordering

Procurement:

- Record purchase date, vendor, purchase price, and warranty information

- Attach invoices and purchase orders directly to asset records

- Track equipment specifications and model numbers for parts ordering

Deployment:

- Assign equipment to specific projects, crews, or locations

- Track utilization rates: Which assets are heavily used vs. sitting idle

- Calculate project-based equipment costs for accurate job costing

Maintenance:

- Schedule preventive maintenance by hours, days, or usage

- Track service history, parts replaced, and maintenance costs

- Store service records for warranty claims and resale documentation

Depreciation:

- Calculate equipment depreciation for financial reporting

- Export asset data to QuickBooks or other accounting systems

- Generate fixed asset reports for tax purposes

Disposition:

- Identify underutilized equipment for sale or rental income

- Track disposal or sale proceeds

- Maintain historical records for audit compliance

Asset Tracking Solutions by Industry

General contractors and commercial construction

Challenges:

- Managing equipment across 5-20 simultaneous projects

- Coordinating with subcontractors who borrow equipment

- Tracking small tools (drills, saws) alongside heavy equipment (lifts, compressors)

- Preventing tool loss when crews move between jobsites daily

GoCodes solution:

- Multi-project dashboard: See equipment distribution across all active jobsites

- Subcontractor equipment loans: Track which GC borrowed your compressor, when it’s due back

- Mixed asset types: Track $50 hand tools and $50,000 excavators in the same system

- Daily check-in workflow: Crews verify all equipment before leaving jobsites

Electrical contractors and specialty trades

Challenges:

- High-value specialized tools (conduit benders, wire pullers, testing equipment)

- Tools distributed across service trucks—need per-vehicle inventory

- Calibration requirements for testing and diagnostic equipment

- Mixed ownership: Company tools, personal tools, rental equipment

GoCodes solution:

- Vehicle-based inventory: Track which tools live in each service truck

- Calibration scheduling: Automate testing equipment certification reminders

- Ownership tracking: Differentiate company-owned from employee-owned tools

- Rental management: Track rental start/end dates, return reminders, rental costs

Heavy civil and infrastructure contractors

Challenges:

- Very high-value equipment: Excavators, graders, pavers ($100,000-$500,000 each)

- Remote worksites miles from the nearest office

- Equipment theft at isolated construction sites

- Mixed fleet: Owned equipment, long-term rentals, short-term rentals

GoCodes solution:

- GPS tracking integration: Real-time location monitoring for all heavy equipment

- Geofencing alerts: Get notified if equipment moves outside project boundaries

- Rental vs. owned tracking: Differentiate rental equipment, track rental periods

- Offline mobile mode: Track equipment at sites without cellular coverage

Residential construction and remodeling companies

Challenges:

- Tools frequently left at customer homes after job completion

- Crews working independently at 10-30 locations simultaneously

- Customer property liability: Proving your tools didn’t damage customer belongings

- Small team budgets: Can’t afford $2,000/month enterprise systems

GoCodes solution:

- Customer site checkout: Scan tools in/out at each residential location

- GPS timestamps: Prove when your equipment left customer properties

- Photo documentation: Show equipment condition before/after jobsite deployment

- Affordable pricing: $150-$400/month for small residential contractors

Mechanical, plumbing and HVAC contractors

Challenges:

- Specialized diagnostic tools: Leak detectors, pressure testers, refrigerant gauges

- Tools stored in service trucks—need per-vehicle accountability

- Expensive hand tools with high theft risk (pipe threaders, crimping tools)

- Technicians working independently across metro areass

GoCodes solution:

- Service truck inventory: Know exactly which tools are assigned to each vehicle

- Technician accountability: Track which employee has each specialized tool

- Maintenance tracking: Schedule calibration for diagnostic equipment

- Quick checkout: Scan tools in/out in 3 seconds when swapping between trucks

Demolition and site preparation companies

Challenges:

- Extreme equipment abuse: Demolition tools take brutal punishment

- Dusty, dirty jobsites hostile to electronics

- High equipment turnover from damage and wear

- Need maintenance tracking to prevent catastrophic equipment failure

GoCodes solution:

- Ultra-durable labels: Metal tags survive demolition environments

- Rugged mobile app: Works on dusty touchscreens with work gloves

- Damage photo documentation: Capture equipment condition before/after jobs

- Maintenance-hour tracking: Service equipment by hours used, not calendar days

GoCodes Complete Solution

Software + Hardware + Labels + Support

Competitors sell software and leave you to figure out the rest. GoCodes provides everything you need:

Cloud-based tracking software:

- Web dashboard for office staff

- Mobile apps for field crews

- Unlimited asset tracking

- Automatic no cost software updates

Rugged QR code labels:

- Professional label design service

- Material recommendations for your equipment types

- Pre-printed labels or print-on-demand

- Multiple durability tiers for different environments

Implementation and Lifetime support:

- Account setup and configuration

- Label design and production

- Team training (web, video, or on-site options)

- 30-minute onboarding call included

- Phone support during business hours

Optional GPS trackers:

- Battery-powered and hardwired options

- Magnetic mounting or permanent installation

- Cellular connectivity included

- Integration with GoCodes platform

Tool Tracking ROI Calculator

How much money are you losing every year due to lost and stolen tools?

Why Customers Choose GoCodes.

See Why Our Customers Rate Us!

GoCodes Asset Tracking

Case Studies

At GoCodes, we pride ourselves on facilitating meaningful asset management. But don’t just take our word for it. Learn how we have created impact for our satisfied users.

FAMILY LEGACY MISSIONS

Transforming Lives In Zambia

J&M Keystone

Flood and Damage Restoration

GoCodes makes asset tracking, easy!

GoCodes Use Cases

Asset Tracking

Instantly track and update the location, condition and status of your assets anywhere, on your phone (No Mobile Apps needed.) End loss and reduce cost.

Calibration Maintenance

Easily monitor, schedule and document equipment calibration and prevent equipment downtime. Now equipment is safe to use and legally compliant.

Compliance Management

Automate schedules, track maintenance history and ensure assets meet regulatory standards for everyone’s safety.

Inventory Tracking

Re-order when inventory levels are low with custom low-stock alerts and put an end to low stock emergencies. Charge inventory usage to departments and projects and increase productivity.

Lifecycle Management

Manage your assets from acquisition to disposal and maximize asset value and their operational efficiency. Use real-time data for asset forecasting, too.

Fixed Asset Management

Calculate depreciation and manage repairs, maintenance and disposal. Streamline year-end financial reporting and tax return filings and get the financials done fast.

Facilities Management

Monitor and manage the location, condition and maintenance of your facility’s physical assets for compliance and optimize their lifespan for an economic win.

Our total solution comes with training & support, included in the base software price. And you get tags, too!

We include patented QR code tags that can be customized to your project. They come ready to use with our web software and smartphone scanner apps.

Works on devices you already own

Our FREE scanner apps and tags mean there's no hand-held barcode scanners or printers to purchase – so you’re up-and-running fast.

Frequently Asked Questions

Learn more about features, security, integration capabilities, and more!

How does asset tracking work for construction companies?

Construction asset tracking uses QR codes, GPS, or RFID tags to monitor tools, vehicles, and equipment in real time. Workers scan tags with any smartphone to record check-in/out and update locations instantly. GoCodes’ patented QR labels work offline and survive harsh job site conditions, syncing automatically when reconnected. You’ll see live visibility across all sites, automatic alerts for missing tools, and maintenance reminders.

What’s the best way to track tools across multiple job sites?

The best multi-site tool tracking system combines QR labels, GPS trackers, and cloud software. QR codes manage small tools; GPS handles vehicles and heavy machinery. GoCodes automatically logs transfers between sites, no spreadsheets or manual updates. Use a location hierarchy (Company → Project → Trailer) and simple scan routines to keep records accurate. Construction firms using this setup cut tool loss by up to 90% and save hours each week.

How do you prevent tool theft on construction sites?

Preventing construction tool theft starts with visible tracking and accountability. GoCodes labels display “This item is tracked,” deterring theft instantly. Each scan logs who has the tool and where it is. GPS geofencing sends alerts if equipment leaves a site. Photo logs, after-hours alerts, and proof-of-ownership records support recovery and insurance claims. Most companies cut tool loss by 90% after adding tracking and worker accountability.

What’s the difference between construction inventory management and asset tracking?

Construction inventory management tracks consumables like lumber and fasteners. Whereas, asset tracking monitors durable equipment like tools, vehicles, and heavy machinery used across multiple projects.

Key Differences Between Inventory Management and Asset Tracking:

Inventory Management

- Focuses on consumables like materials and supplies

- Tracks quantities (e.g., “How many 2x4s do we have?”)

- Items deplete with use

- Involves restocking and ordering workflows

- Emphasizes cost tracking per project

- Manages warehouse and supplier relationships

Asset Tracking

- Focuses on durable equipment like tools and vehicles

- Tracks locations (e.g., “Where is the excavator?”)

- Items are reused across projects

- Uses check-in/check-out workflows

- Emphasizes utilization and maintenance tracking

- Supports multi-site location management

What types of construction equipment can GoCodes track?

GoCodes tracks any physical asset your construction company needs to manage: Hand tools (drills, saws, hammers, measuring equipment), Power tools (rotary hammers, impact drivers, pneumatic nailers, grinders), Heavy equipment (excavators, skid steers, loaders, forklifts, boom lifts), Vehicles (trucks, trailers, service vans), Generators and compressors, Welding equipment, Safety gear (harnesses, hard hats, protective equipment requiring periodic inspection), Ladders and scaffolding, Materials (lumber inventory, concrete forms, piping).

How does maintenance scheduling work for construction equipment?

GoCodes automates preventive maintenance to extend equipment life and prevent breakdowns. Set maintenance intervals by engine hours, calendar days, or usage cycles, such as servicing excavators every 250 hours, inspecting fall protection equipment every 90 days per OSHA requirements, or replacing saw blades after 100 cuts. The system calculates next service dates automatically and sends email or SMS reminders to equipment managers before maintenance becomes overdue. Track completed service activities, attach receipts and work orders, and build complete service history for warranty claims and resale documentation.

How much does GoCodes cost for contractors?

GoCodes plans for contractors typically range from $1,000 to $4,000+ per year, depending on how many assets you need to track and how many team members need access.

Articles & Insights

Information to give you more tracking power

5 Common Challenges of Construction Reporting

Key Takeaways: 91% of construction teams still use paper in their processes, increasing errors and slowing decisions. Project teams spend 13 hours weekly searching for fragmented data across systems. Inconsistent standards and naming conventions make construction...

Best Construction Material Management Software

Discover the top material management tools for construction teams. Our guide will show you how to track inventory.

Best Ways to Prevent Theft On Your Construction Site

Want to reduce theft-related losses? This article covers smart and proven strategies for construction site theft prevention.

Construction Daily Reports: Why They Matter and How to Write Them

Want to improve your construction reporting process? This article will show you why daily reports matter and how to create them effectively.

6 Types of Construction Project Management Software

Find out which types of software you should consider using if you want to elevate your approach to construction project management.